A non-contact sensor circuit

A non-contact sensor, non-contact coupling technology, applied in the direction of instruments, measuring electricity, measuring electrical variables, etc., can solve the problems of unfavorable detection circuit stable operation, complex circuit structure, large output DC drift, etc., and achieve good physical realizability , The circuit structure is simple, and the effect of increasing the filtering characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

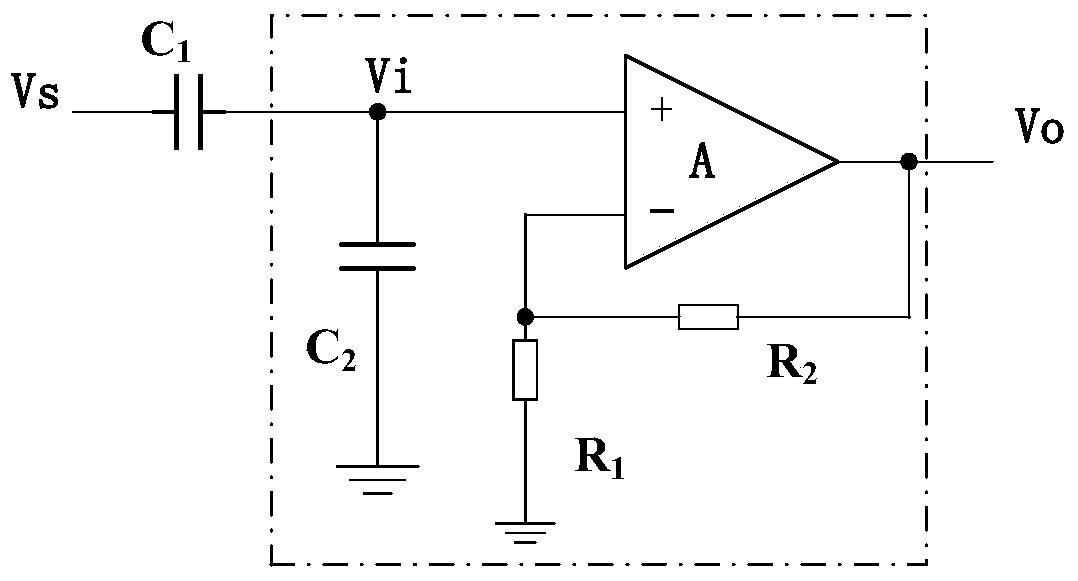

Embodiment 1

[0029] see figure 1 , including only the detection part and the basic part of the circuit. The detection part is realized by capacitive coupling, and the capacitive coupling device commonly used in the prior art can be used as the detection component to detect the measured signal Vs, and the measurement signal is generated and transmitted to the circuit input terminal Vi. The equivalent circuit diagram is as follows figure 1 The capacitance C shown 1 part. The basic part of the circuit consists of capacitor C 2 , resistor R 1 , resistor R 2 and op amp A, capacitor C 2 One end is connected to the detection signal and the non-inverting input of the operational amplifier A, and the other end is grounded; the resistor R 1 One end of the resistor is connected to the inverting input of the operational amplifier A, and the other end is grounded; the resistor R 2 One end of A is connected to the inverting input of the operational amplifier A, and the other end is connected to t...

Embodiment 2

[0033] see figure 2 , including the detection part and the circuit part. The detection part remains unchanged, and the circuit part is in figure 1 circuit basis, the capacitor C 1 A capacitor C is connected in series with the connection circuit of the non-inverting input of the operational amplifier A 3 , the capacitor C 3 The output drift of the circuit can be reduced when the input coupling capacitance is large.

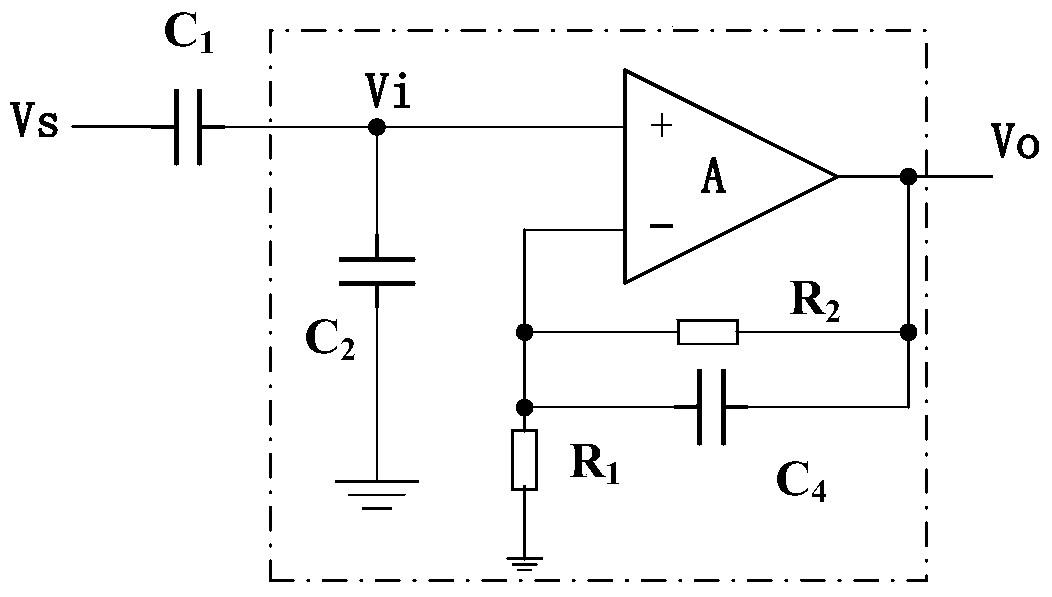

Embodiment 3

[0035] see image 3 , including the detection part and the circuit part. The detection part remains unchanged, and the circuit part is in figure 1 circuit based on the resistor R 2 Connect both ends of the capacitor C 4 , realize low-pass filtering, limit the detection signal bandwidth, and reduce the noise floor of the circuit at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com