Bucket elevator tail wheel transmission bearing air sealing and dust leakage detection device

A technology of leak detection device and transmission bearing, which is applied to the sealing of the engine, the use of liquid/vacuum for liquid tightness measurement, bearing components, etc., to facilitate manual on-site observation, eliminate serious wear and deformation, and facilitate dust leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

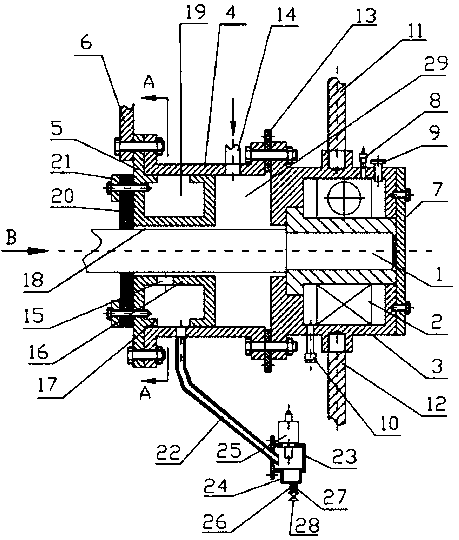

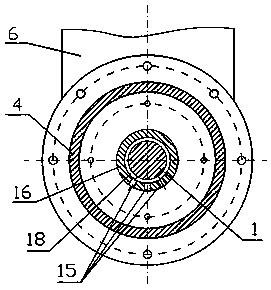

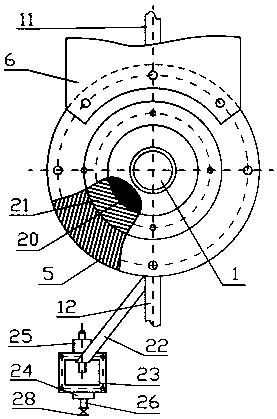

[0022] The specific embodiment of the present invention is described below in conjunction with accompanying drawing, as figure 1 , figure 2 and image 3 As shown, the technical solution adopted by the present invention is: the gas sealing and dust leakage detection device of the tail wheel transmission bearing of the bucket elevator, including the gas sealing device and the dust leakage detection device of the transmission bearing, wherein the gas sealing device of the transmission bearing includes the transmission shaft 1. Bearing 2, bearing seat 3, sealing sleeve 4, inner sleeve 5, sealing plate 20, fixing flange 21 and fixing frame 6, characterized in that: the two ends of the transmission shaft 1 are fixedly connected to the bearing 2, and the bearing 2 is externally provided with bearings Seat 3, the end of the bearing seat 3 is provided with a sealing cover 7, the sealing cover 7 is fixedly connected with the bearing seat 3 through bolts, the upper part of the bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com