Plain soil compaction pile device and construction method

A technology for compacting piles and equipment, which is used in soil protection, infrastructure engineering, construction, etc., and can solve problems such as limited processing depth and insufficient pile depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

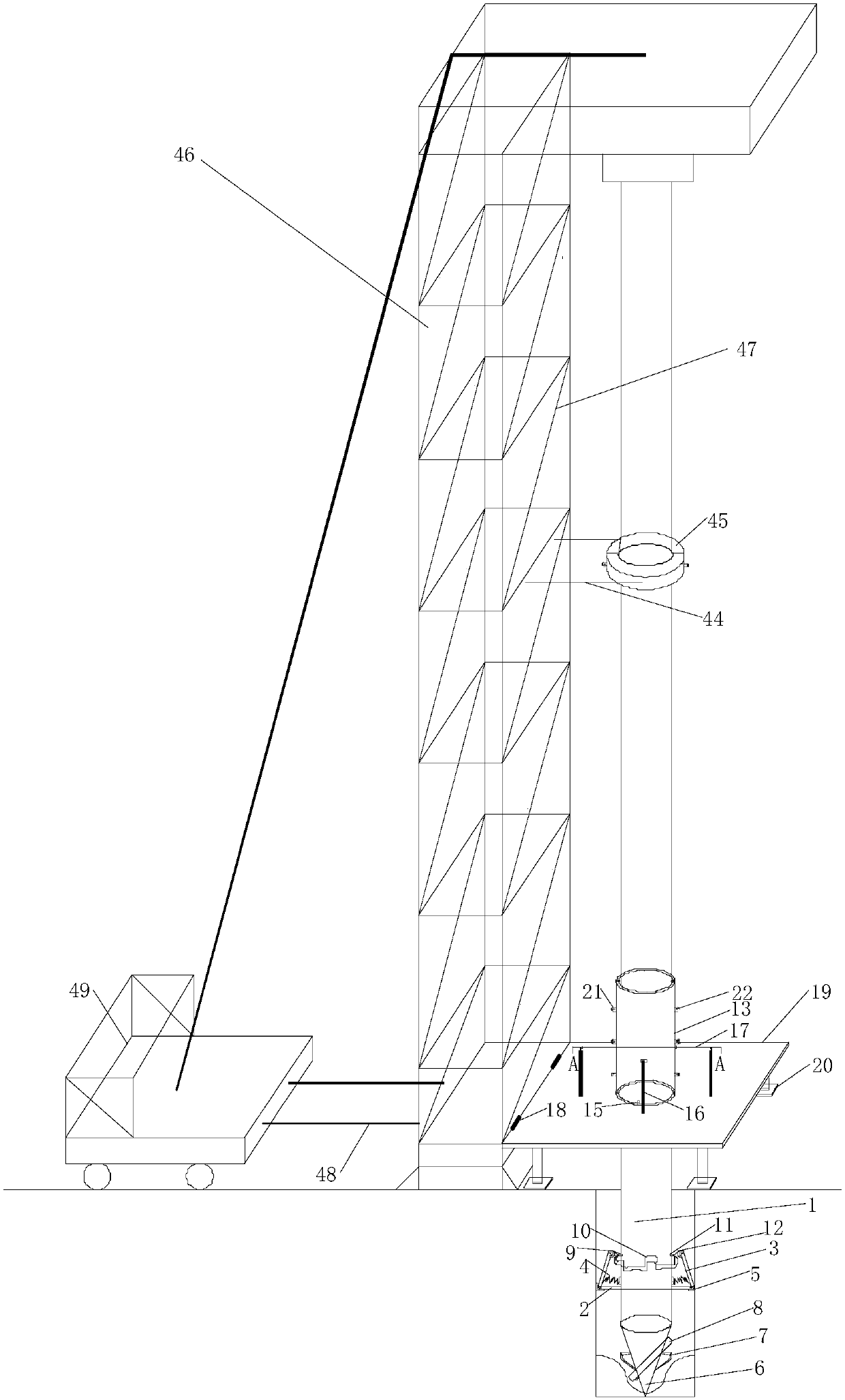

[0062] Specific implementation examples

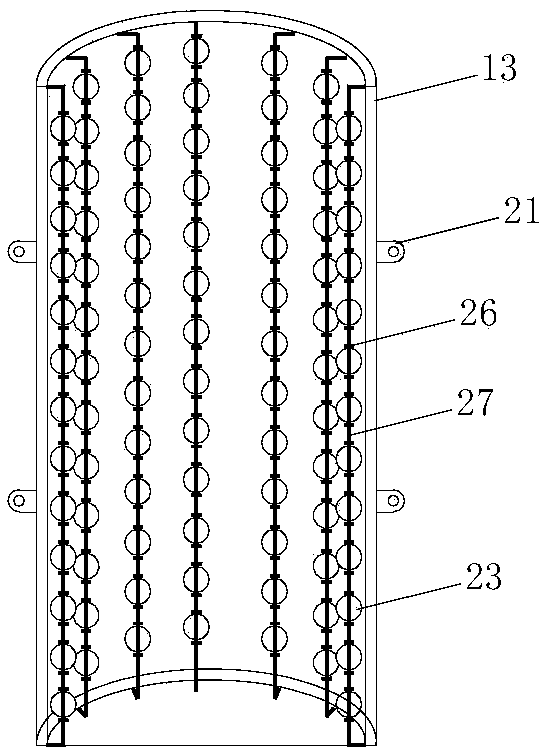

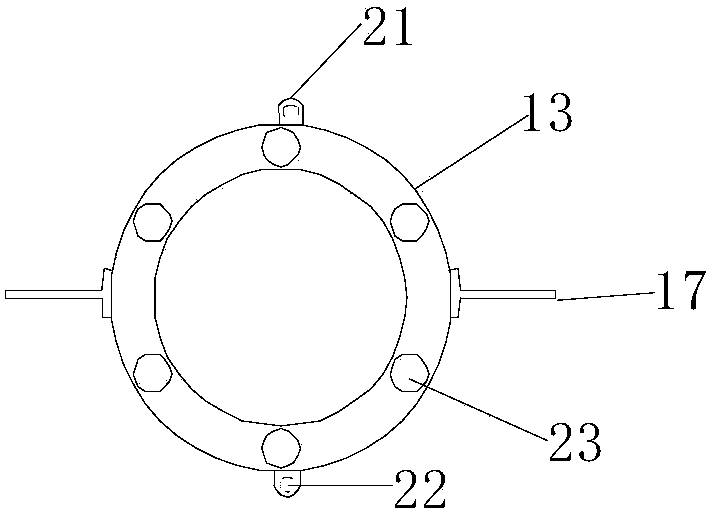

[0063] Plain soil compaction pile equipment mainly includes: hole-forming equipment, tamping equipment and supporting equipment. Hole-forming equipment consists of immersed tubes, movable pile tips, bladders, and fixed barrels; ramming equipment consists of rammers, rammers, rammer corner plates, and control rods; supporting equipment consists of support frames, support rods, and mobile vehicles. composition. The main steps of the construction method are: on-site installation of hole-forming equipment, supporting equipment, and compacting equipment; sinking with a hammer sinking tube compaction pile machine according to the designed pile length; water injection and humidification during the hole-forming process; pulling out the pipe after hole-forming , Pull out the pipe for the second punching, use tamping equipment to tamp down the fallen soil, and then the filler is tamped layer by layer to complete the construction.

[0064] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com