Preparation method of acidized soil conditioner

A soil conditioner and a technology for preparation steps, applied in soil conditioning materials, chemical instruments and methods, other chemical processes, etc., can solve the problems of aggravating soil acidification, increasing the frequency of acid rain, air pollution, etc. Stabilizing, deepening aromatization, and promoting effects of reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

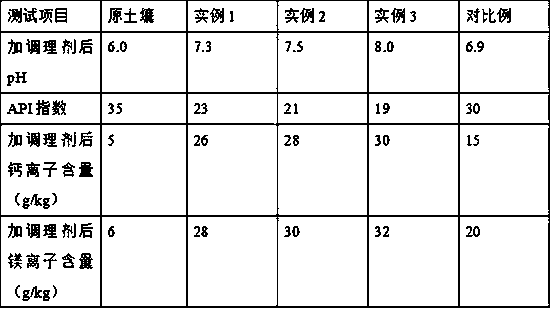

Examples

example 1

[0023] Weigh 20g of oyster shells and 10g of shrimp shells, mix and crush them for 10 minutes, wash the crushed mixed shells with deionized water, remove the filter residues, put them in a muffle furnace, roast them at 1000°C for 1 hour, and take out the roasted filter residues , continue to grind for 12 minutes and then sieve through a 100-mesh sieve to collect the sieved crushed shell powder, put the sieved crushed shell powder into a beaker, add deionized water of 1 times the mass of the above-mentioned sieved crushed shell powder to the beaker, mix and place Heat and stir in an electric furnace at 50°C for 20 minutes, then put it into an oven, and dry at 60°C for 10 minutes to obtain self-made bioactive calcium. Mix boron mud and zeolite in a crushing machine at a mass ratio of 1:1 Pulverize 16min and cross 80 mesh sieves, collect the sieved powder, put the sieved powder into a fermenter with 6% amber of the sieved powder quality and 0.5% of the sieved powder quality 0.5% o...

example 2

[0025]Weigh 25g of oyster shells and 15g of shrimp shells, mix and crush them for 11 minutes, wash the crushed mixed shells with deionized water, remove the filter residue, put them in a muffle furnace, and roast them at 1100°C for 1.5 hours, take out the roasted Filter the residue, continue to grind for 14 minutes and then sieve it through a 100-mesh sieve, collect the sieved crushed shell powder, put the sieved crushed shell powder into a beaker, add deionized water twice the mass of the above-mentioned sieved crushed shell powder to the beaker, mix and place Heat and stir in an electric furnace at 52°C for 25 minutes, then put it in an oven, and dry it at 70°C for 11 minutes to obtain self-made bioactive calcium. Mix boron mud and zeolite with a mass ratio of 1:1 and place it in a crusher Medium crushing for 18 minutes and passing through an 80-mesh sieve, collecting the sieved powder, putting the sieved powder into a fermenter with 6% amber of the sieved powder mass and 0.5...

example 3

[0027] Weigh 30g of oyster shells and 20g of shrimp shells, mix and crush them for 12 minutes, wash the crushed mixed shells with deionized water, remove the filter residues, put them in a muffle furnace, roast them at 1200°C for 2 hours, and take out the roasted filter residues , continue to grind for 16 minutes and then 100 mesh sieve, collect the sieved crushed shell powder, put the sieved crushed shell powder into a beaker, add deionized water 3 times the mass of the sieved crushed shell powder to the beaker, mix and place Heat and stir in an electric furnace at 55°C for 30 minutes, then put it in an oven, and dry it at 80°C for 12 minutes to obtain self-made bioactive calcium. Mix boron mud and zeolite with a mass ratio of 1:1 and place them in a crusher Pulverize 20min and pass through 80 mesh sieves, collect the sieved powder, put the sieved powder into a fermenter with 6% of the sieved powder quality amber and 0.5% sieved powder quality of river bottom sludge, and seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com