Nanometer heat-insulating coating

A nano thermal insulation and coating technology, applied in the field of coatings, can solve problems such as poor thermal insulation effect, and achieve the effects of improving mechanical properties, increasing porosity, and improving thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Specific embodiments of the present invention will be described in detail below.

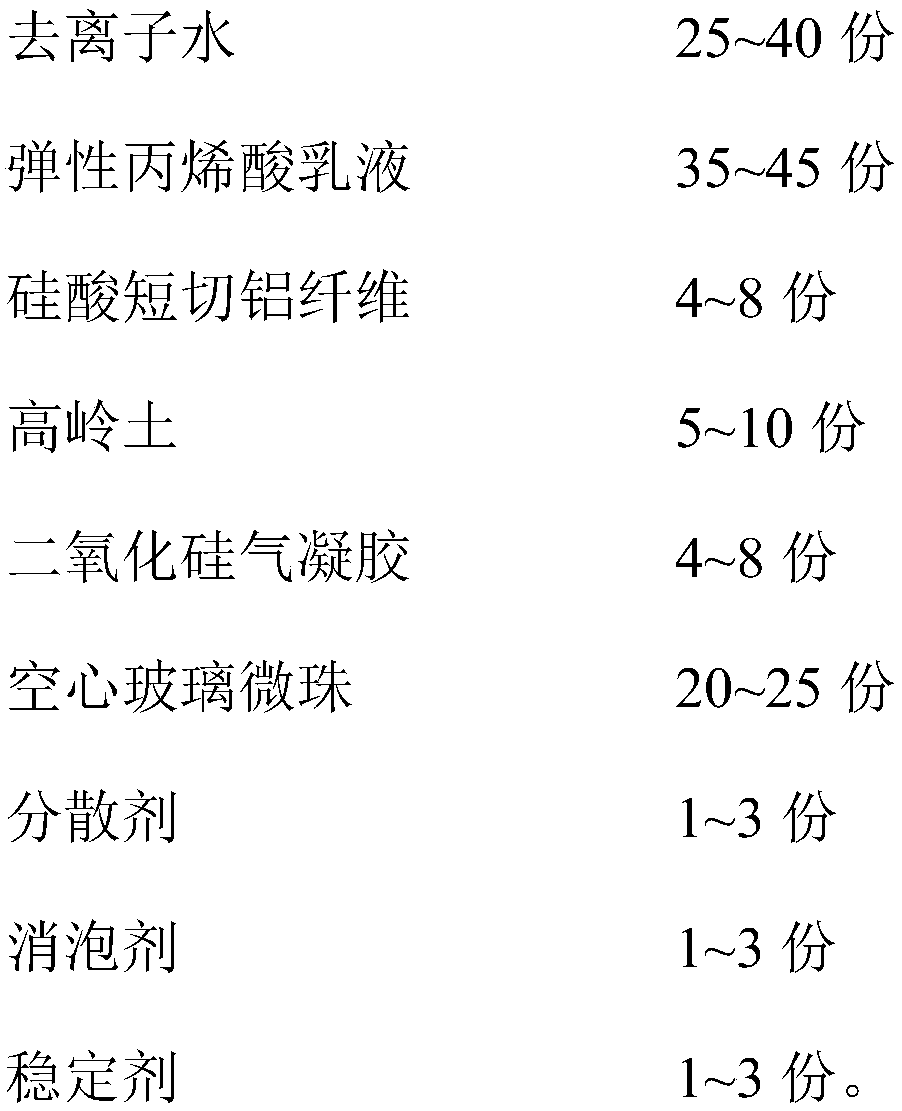

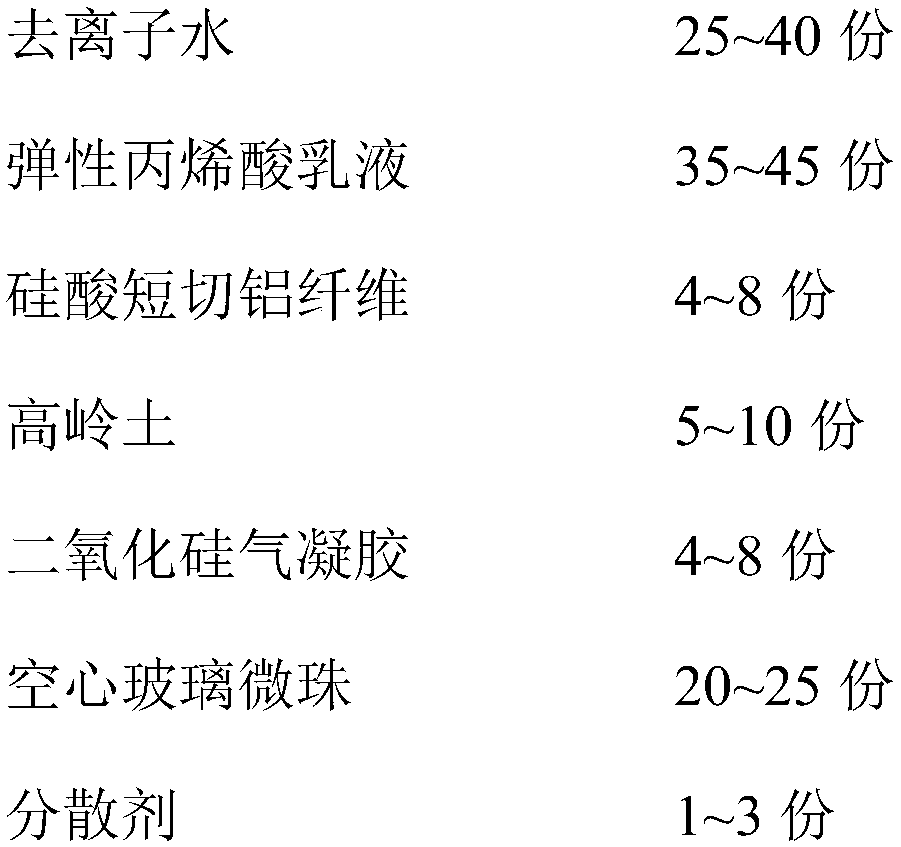

[0010] A kind of nano heat insulating paint, comprises following component and the weight ratio of each component is:

[0011]

[0012]

[0013] The beneficial effects of the present invention are: 1) The self-crosslinking elastic acrylic emulsion is selected as the film-forming material, which has high solid content, low film-forming temperature, and surface UV curing, and has excellent elasticity and high viscosity at a wide temperature. 2) The added silica airgel is a nano-scale three-dimensional network skeleton structure formed by the interconnection and aggregation of several Si-O-Si groups. Due to the existence of nearly infinite nanopores, the solid heat transfer can only be transmitted along the pore wall, and the nearly infinite pore wall constitutes a nearly "infinite long path" effect, which makes the thermal conductivity of the solid drop to almost the lowest limit; 3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com