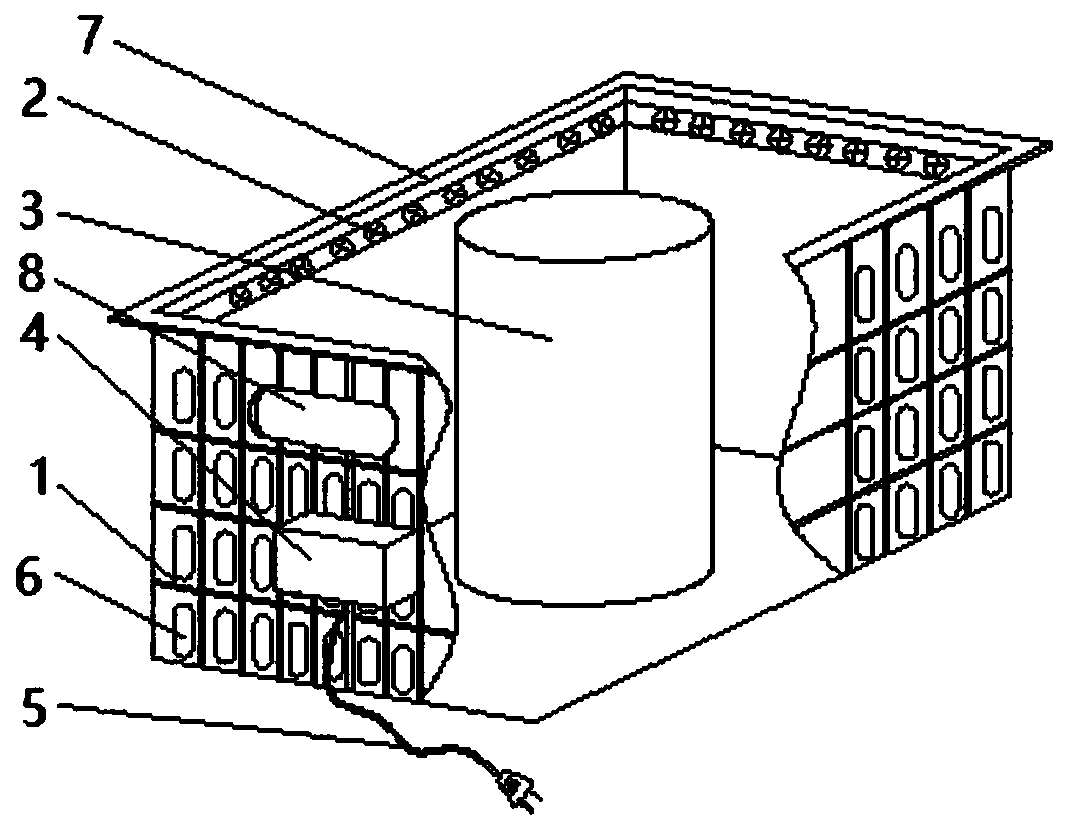

Factory-like plant tissue culture method and culture box implementing same

A plant tissue culture and incubator technology, which is applied in botany equipment and methods, plant regeneration, gardening methods, etc., can solve the problems of vacant upper bed frame, low space utilization rate, and many dead spots, so as to improve work efficiency and save The effect of controlling temperature cost and increasing the amount of culture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

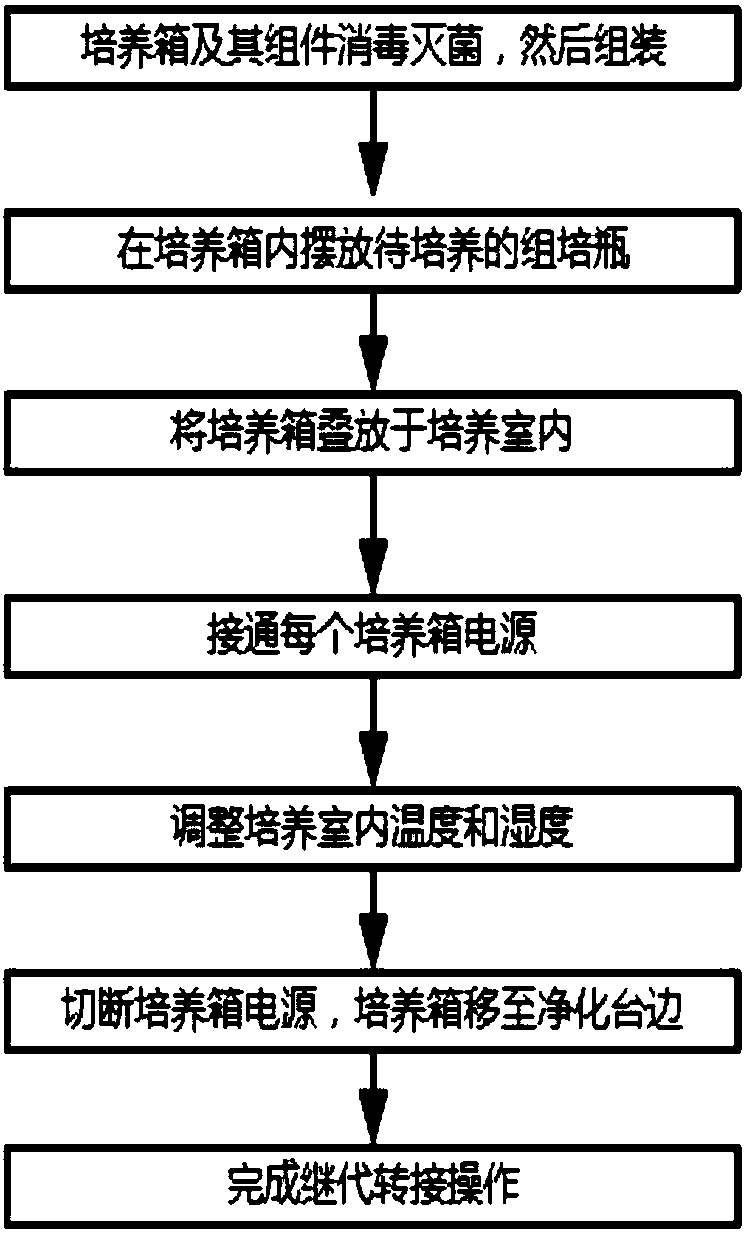

Embodiment 1

[0038] The method of plant tissue culture of the present invention mainly includes the following steps: 1) Disinfect and sterilize the incubator used for plant tissue culture and all its components, and then assemble them, wherein the power supply components or connectors in the components are not used during cleaning. Disinfectants that can cause electric leakage; 2) Place the tissue culture bottles to be cultured in the assembled incubator; 3) Stack the incubators containing the tissue culture bottles in the culture room, leaving a channel between every two rows , The distance between the channels is 60cm, and then turn on the power of each incubator; 4) adjust the temperature and humidity in the incubation room to the required range; 5) cut off the power supply of the incubator one by one when transferring Move the box to the clean bench to complete the transfer operation; 6) After the transfer is completed, put the new tissue culture bottle back into the original box or repl...

Embodiment 2

[0050] The method of plant tissue culture of the present invention mainly includes the following steps: 1) Disinfect and sterilize the incubator used for plant tissue culture and all its components, and then assemble them, wherein the power supply components or connectors in the components are not used during cleaning. Disinfectants that can cause electric leakage; 2) Place the tissue culture bottles to be cultured in the assembled incubator; 3) Stack the incubators containing the tissue culture bottles in the culture room, leaving a channel between every two rows , The distance between the channels is 70cm, and then turn on the power of each incubator; 4) adjust the temperature and humidity in the incubation room to the required range; 5) cut off the power supply of the incubator one by one when transferring Move the box to the side of the clean bench to complete the transfer operation; 6) When emptying the incubation room, cut off the power of the incubator one by one, move th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com