Mobile motherboard heat dissipation graphite sheet and mobile phone

A technology of graphite sheet and mobile phone, applied in the direction of telephone structure, cooling/ventilation/heating transformation, etc., can solve the problems of low strength, easy to be torn, cannot be reused, etc., so as to reduce production cost and improve bonding quality , The effect of solving the problem of sleepiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

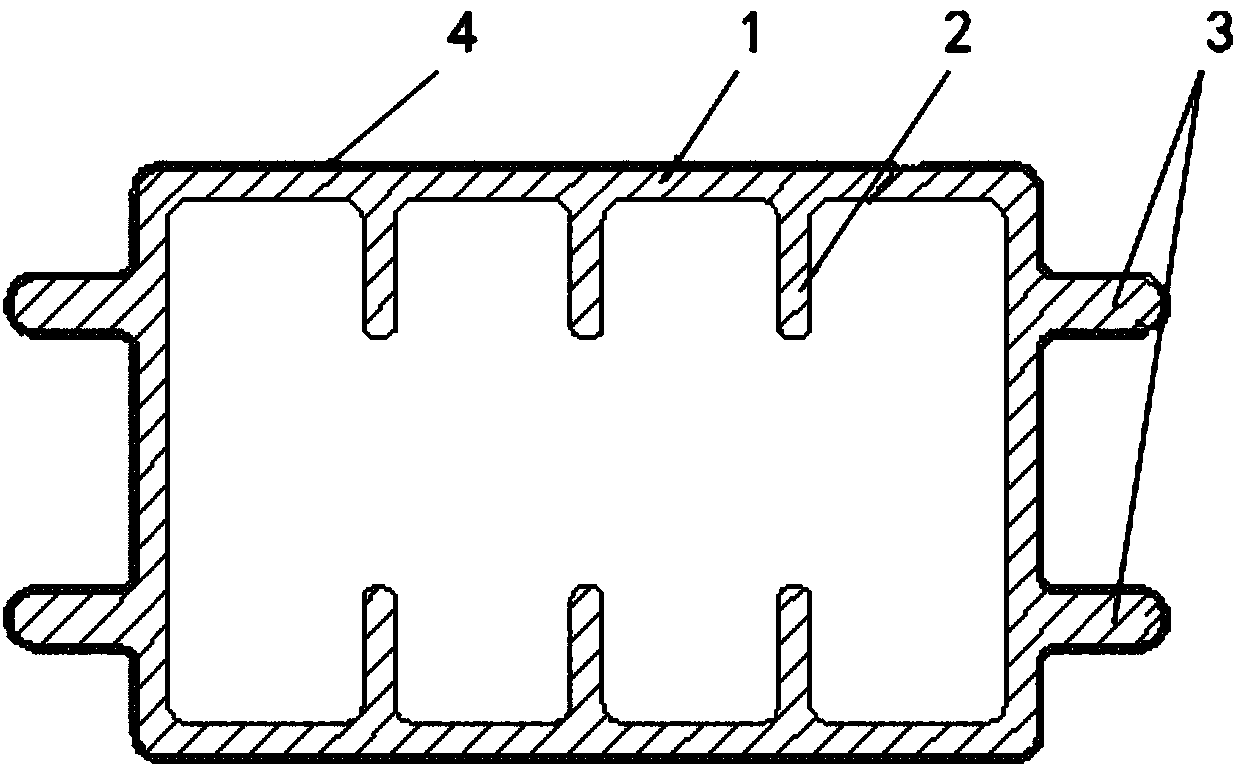

[0018] like figure 1 As shown, the embodiment of the present invention provides a kind of heat-dissipating graphite sheet for mobile phone motherboard, including graphite substrate 5, release film and between graphite substrate 5 and release film, a double-sided adhesive layer is provided, and it is characterized in that, also includes A font-shaped heat dissipation pipe 1, a number of inner fins 2 are evenly distributed in a symmetrical structure on the corresponding two sides of the pipe wall of the heat dissipation pipe 1, and the inner fins 2 are embedded in the graphite matrix 5, and the heat dissipation pipe 1 Wrapped outside the graphite matrix 5, the other corresponding two sides of the tube wall of the heat dissipation tube 1 are symmetrically d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com