A kind of coal-water slurry additive and its preparation method and application

A coal-water slurry and additive technology, applied in the field of coal-water slurry additives, can solve the problems of large feeding volume, poor fluidity, easy to block transportation pipelines, etc., and achieve the effect of strong adaptability and accurate judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The coal water slurry additive in this embodiment is made of the following raw materials in mass percentage: 10% of β-naphthalene sulfonate sodium formaldehyde condensate, 30% of sodium lignosulfonate, and the balance is water.

[0034] The preparation method of the β-naphthalenesulfonate sodium formaldehyde condensate of the present embodiment may further comprise the steps:

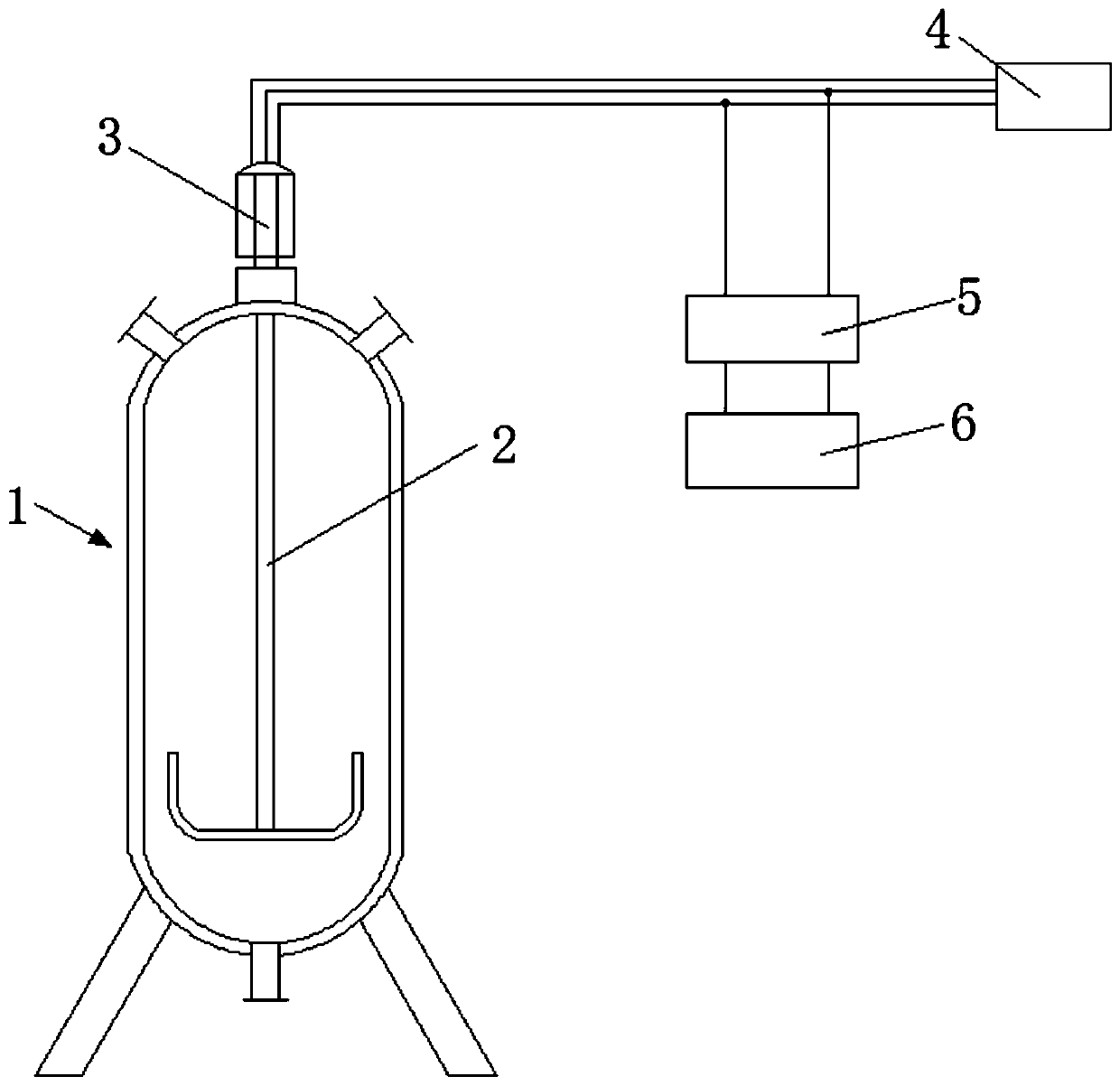

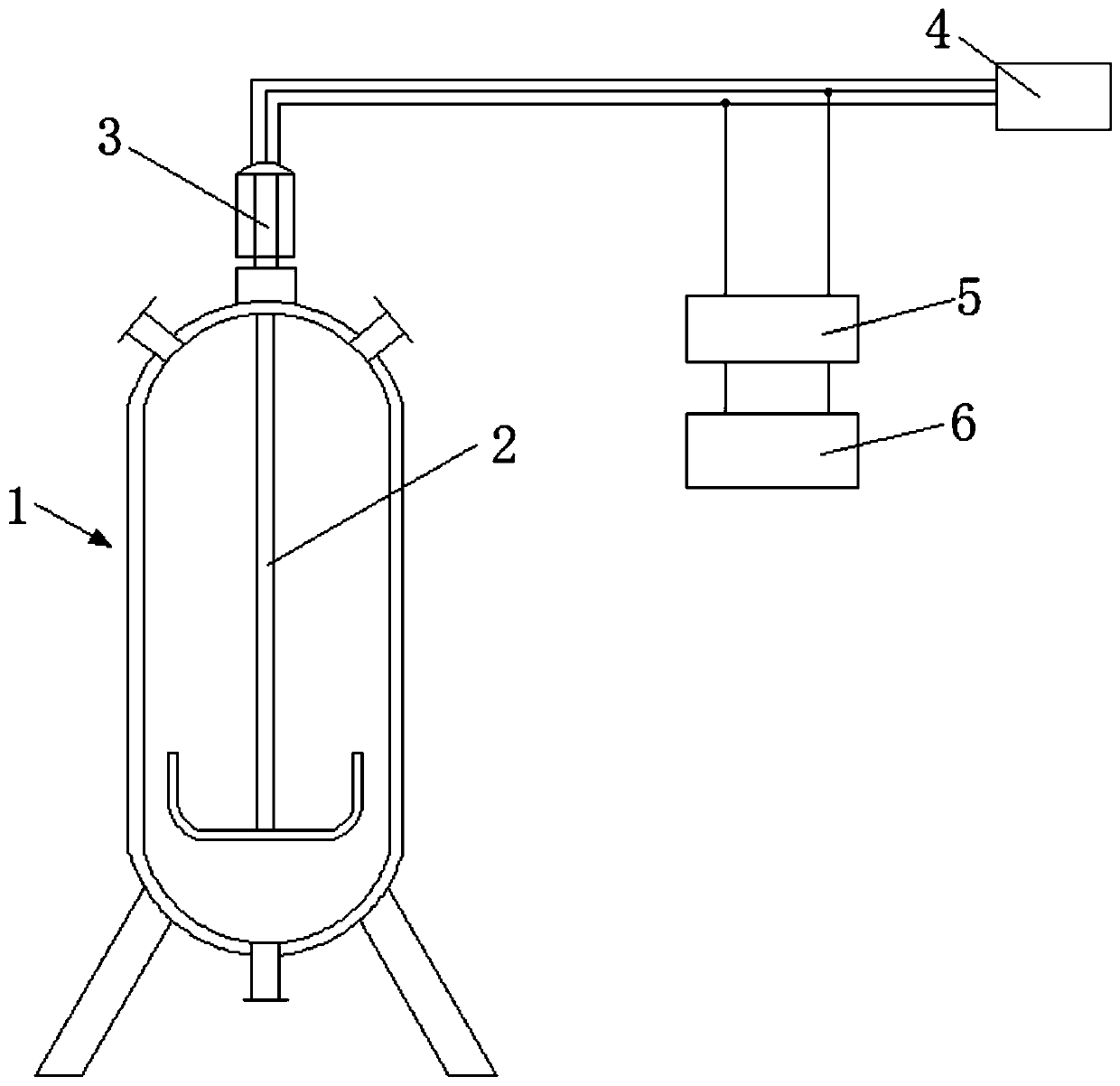

[0035] Step 1, preparation of sodium β-naphthalene sulfonate: 2.5 tons of industrial naphthalene is placed in reactor 1, sealed reactor 1, and melted at 135°C. After industrial naphthalene is completely melted, 1.6 tons of concentrated Sulfuric acid (national standard) is added to the reaction kettle 1 at a feeding rate of 0.8 tons / hour for sulfonation reaction with industrial naphthalene. After all the concentrated sulfuric acid is added, the temperature is raised to 165°C by steam and the reaction is continued for 2 hours, and then 1 ton of water is added. Carry out hydrolysis reaction, cool do...

Embodiment 2

[0049] The coal water slurry additive in this embodiment is made of the following raw materials in mass percentage: 30% of β-naphthalene sulfonate sodium formaldehyde condensate, 10% of sodium lignosulfonate, and the balance is water.

[0050] The preparation method of the β-naphthalenesulfonate sodium formaldehyde condensate of the present embodiment may further comprise the steps:

[0051] Step 1, preparation of β-naphthalene sodium sulfonate: 2.5 tons of industrial naphthalene is placed in reactor 1 and melted under the condition of 130° C., after industrial naphthalene is completely melted, 1.5 tons of vitriol oil (national standard) Add the feed rate of 0.5 tons / hour to the reaction kettle 1 for sulfonation reaction with industrial naphthalene. After adding all the concentrated sulfuric acid, raise the temperature to 160°C and continue stirring for 2 hours, then add 0.875 tons of water to carry out the hydrolysis reaction, and the hydrolysis reaction is over. Then cool do...

Embodiment 3

[0059] The coal water slurry additive in this embodiment is made of the following raw materials in mass percentage: 20% of β-naphthalene sulfonate sodium formaldehyde condensate, 20% of sodium lignosulfonate, and the balance is water.

[0060] The preparation method of the β-naphthalenesulfonate sodium formaldehyde condensate of the present embodiment may further comprise the steps:

[0061] Step 1, preparation of β-naphthalene sodium sulfonate: 2.5 tons of industrial naphthalene is placed in reactor 1, and it is melted under the condition of 140°C at a temperature. After the industrial naphthalene is completely melted, 1.65 tons of concentrated sulfuric acid (national standard ) was added to the reaction kettle 1 at a feed rate of 1 ton / hour to carry out sulfonation reaction with industrial naphthalene. After all the concentrated sulfuric acid was added, the temperature was raised to 170° C. and the reaction was continued for 1 hour, and then 1.075 tons of water was added to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com