IZO sintered compact sputtering target and method for producing same

A manufacturing method and a technology for sputtering targets, which are applied in the directions of sputtering plating, ion implantation plating, coating, etc., can solve the problems of inability to obtain density, increase, etc. The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

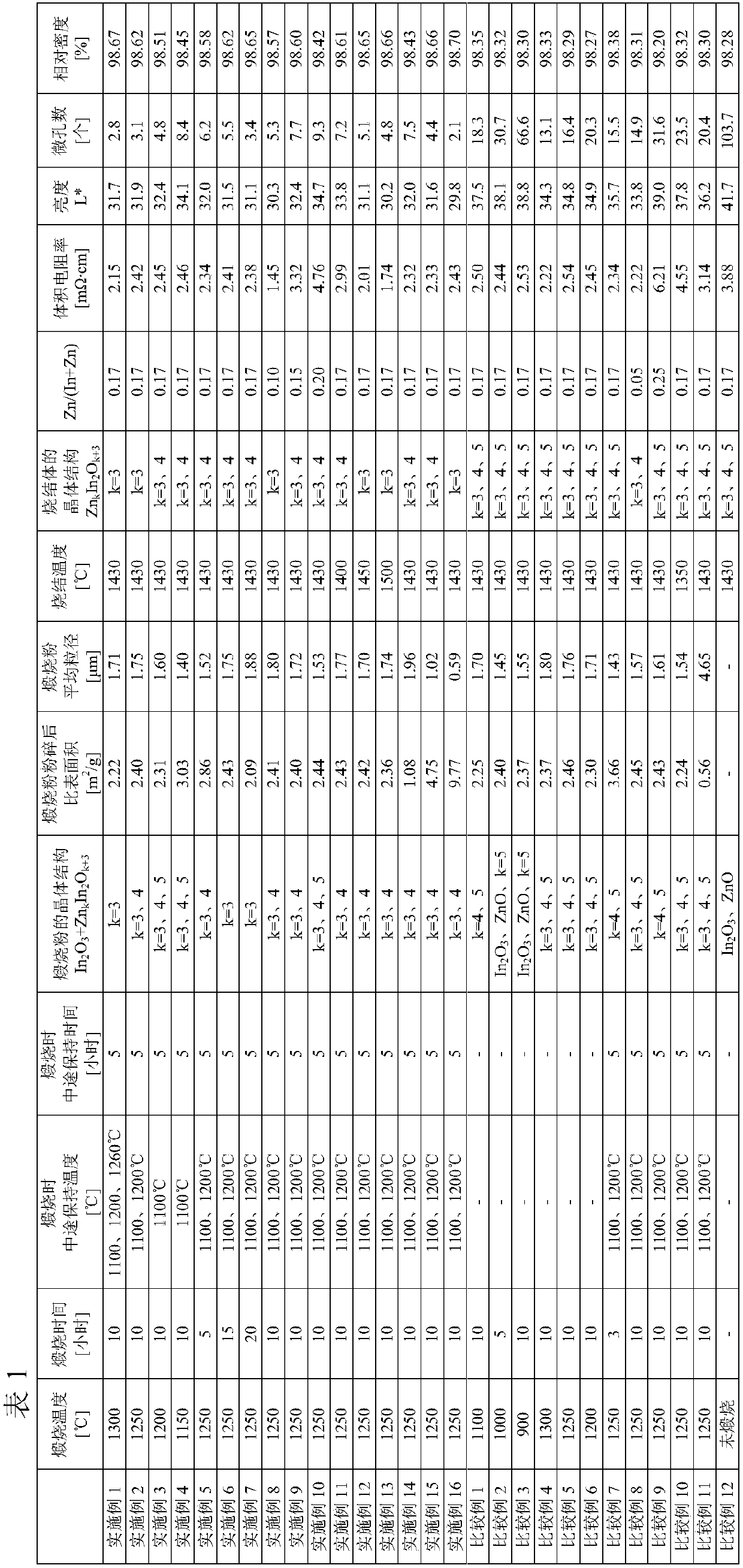

[0064] Indium oxide powder and zinc oxide powder were mixed at a predetermined ratio, and the mixed powder was calcined at 1300° C. for 10 hours in an air atmosphere. In addition, during the calcination process, it is kept at 1100°C, 1200°C, and 1260°C for a certain period of time. The oxide structure of the calcined powder is In 2 o 3 and Zn k In 2 o k+3 (k=3) Composite oxide. The calcined powder is finely pulverized using a jet mill pulverizer and a wet media agitation mill, and then granulated to obtain a specific surface area of 2.22m 2 / g, particles with an average particle size of 1.71 μm. This is then molded to produce a molded body composed of IZO.

[0065] Next, this molded body was held in an oxygen atmosphere at a sintering temperature of 1430° C. for 14 hours to manufacture an indium oxide-zinc oxide-based oxide (IZO) sintered body. The atomic ratio Zn / (In+Zn) of the sintered body to In is 0.17, and the oxide structure of the sintered body is In 2 o 3 a...

Embodiment 2-16

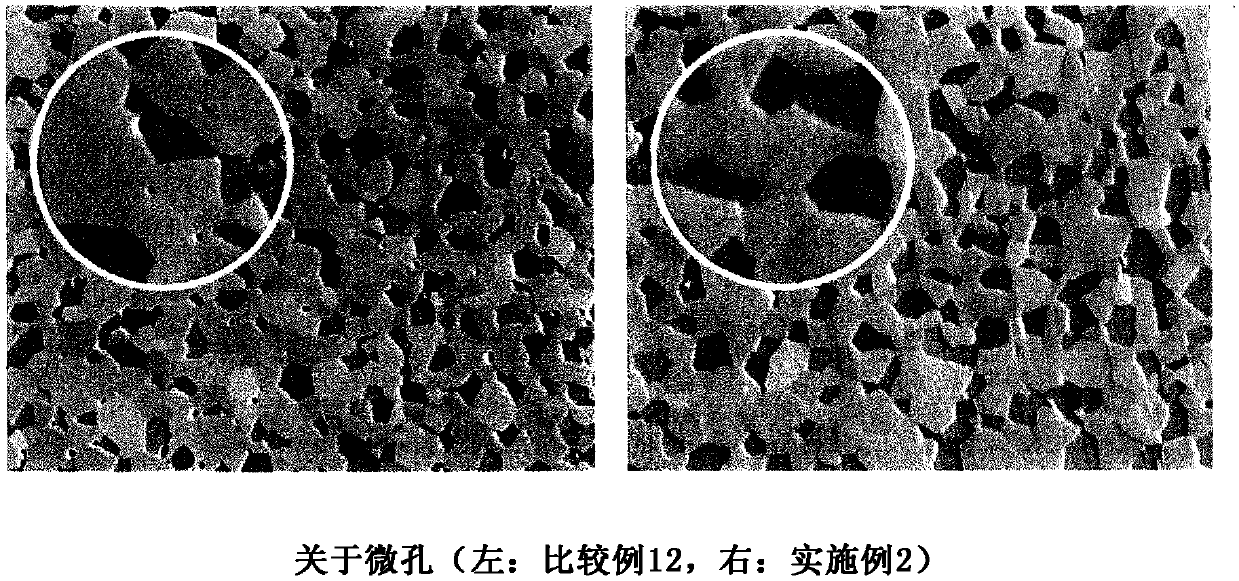

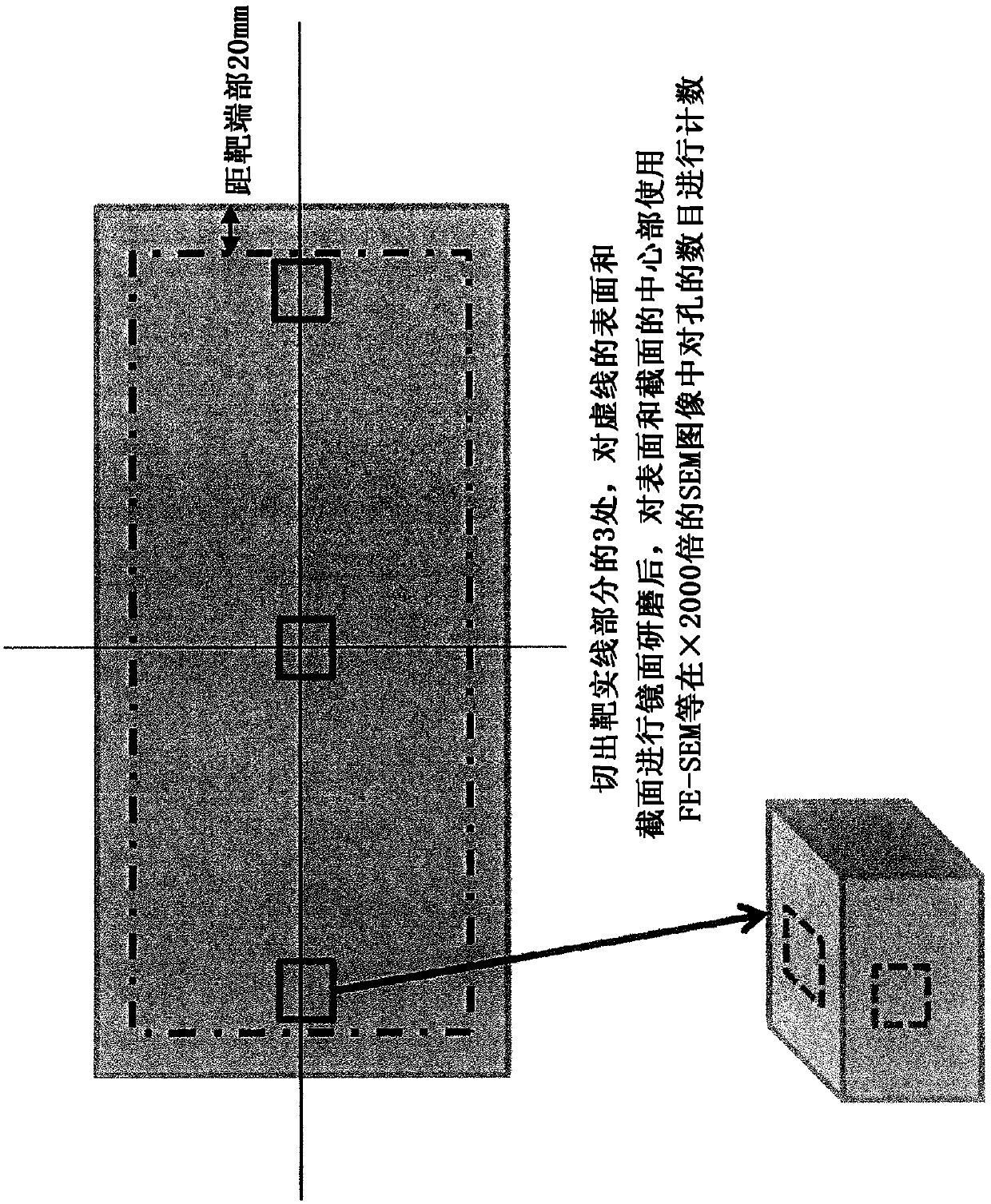

[0070] In Examples 2-16, as shown in Table 1, the calcination conditions (calcination temperature, calcination time, intermediate retention temperature during calcination, intermediate retention time during calcination), pulverization conditions of calcined powder, sintering conditions (sintering temperature, sintering time), the composition ratio of the sintered body (mixing ratio of raw materials, etc.) conditions. As a result, as shown in Table 1, an ideal IZO sintered body sputtering target with high relative density and low brightness could be produced. Sputtering was performed using this sputtering target. As a result, even after long-term sputtering, the generation of nodules on the target surface can be suppressed, and the generation of arc discharge can be suppressed. Produce powder and other effects on the surface. Furthermore, stable thin film characteristics (uniformity of film) are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com