Single-phase five-level boost power factor correction converter

A power factor correction and five-level technology is applied in the direction of converting AC power input to DC power output, output power conversion device, and high-efficiency power electronic conversion. Large waves and other problems, to achieve the effect of reducing the heating of the inductor, reducing the total volume, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

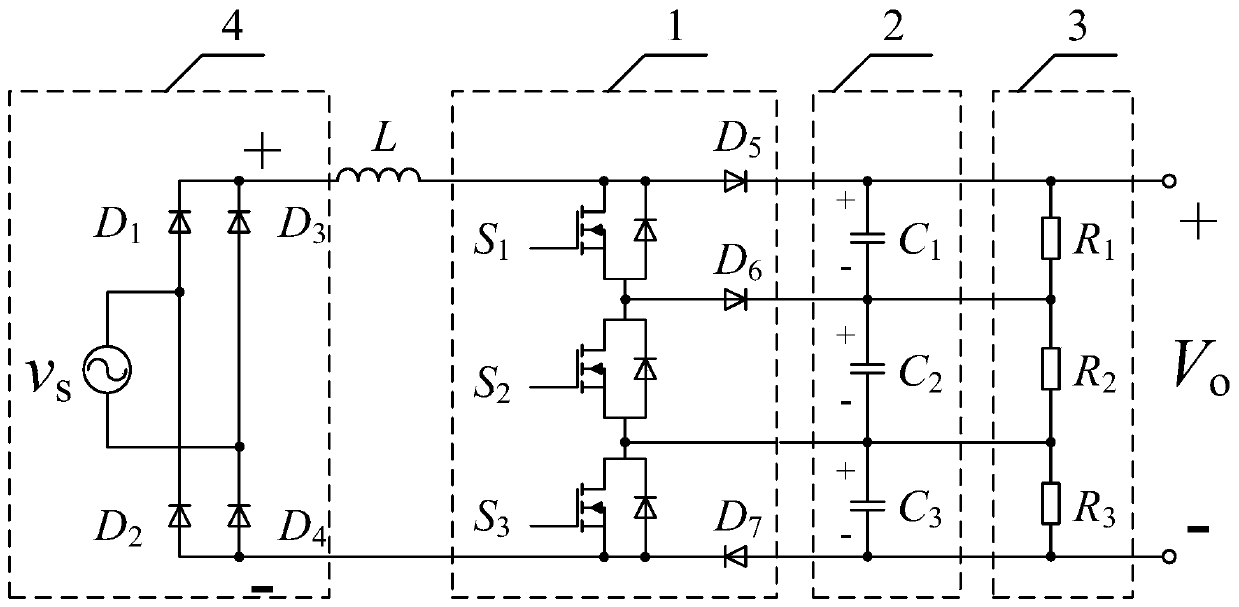

[0024] like figure 1 Shown is a specific circuit diagram of the single-phase five-level Boost power factor correction converter of the present invention. The converter includes a diode single-phase full-bridge rectifier circuit 4 , a Boost boost inductor L, a power electronic switch network 1 , a series capacitor network 2 and a parallel resistor network 3 . The Boost boost inductor L is connected between the DC positive pole of the diode single-phase full-bridge rectifier circuit 4 and the first terminal of the power electronic switch network 1, and the second terminal of the power electronic switch network 1 is connected to the DC negative pole of the diode single-phase full-bridge rectifier circuit 4 .

[0025] The power electronic switching network 1 includes an N-channel MOSFET switching tube S 1 , N-channel MOSFET switch tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com