Sample injection and online pretreatment system and method

A sample injection and sampler technology, which is applied in the field of sample injection and online pretreatment system for atmospheric particle analysis, can solve the problems of high background value of PAEs, time-consuming pretreatment process, and large amount of organic solvent, so as to reduce pollution. The effect of source, saving manpower and reducing the loss of samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

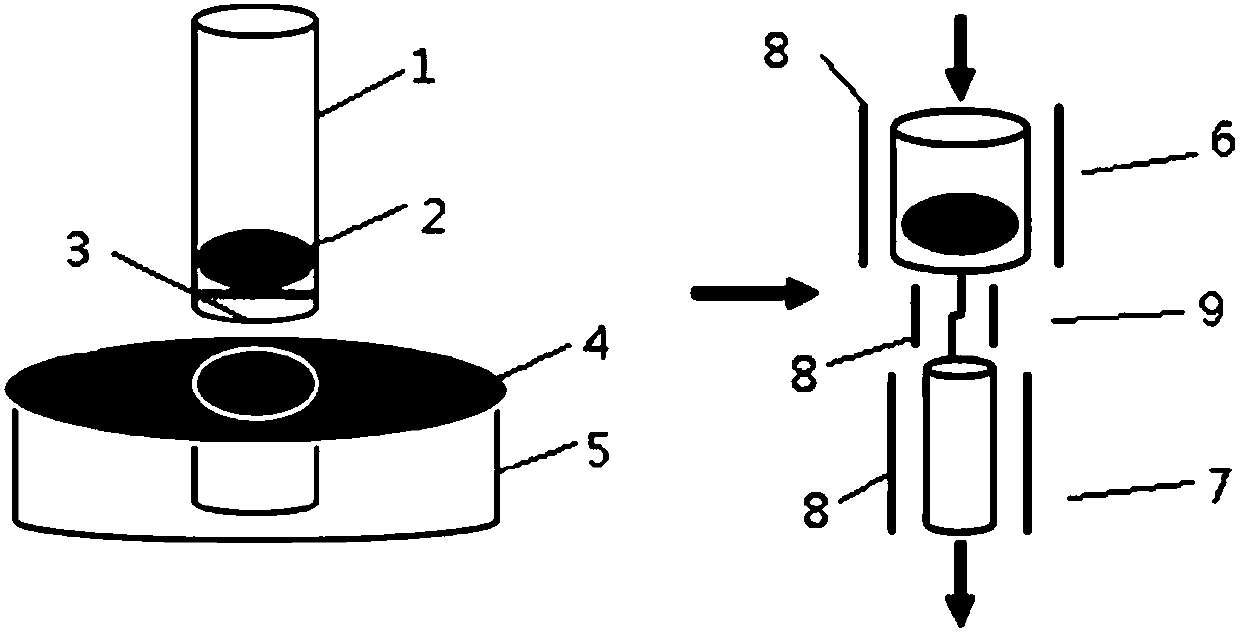

[0046] The detection of phthalates in the atmospheric particulate matter of embodiment 1

[0047] 1. Utilize the atmospheric particulate matter sampling filter membrane 4 to collect atmospheric particulate matter (such as TSP, PM10, PM2.5, etc.). The collection method can be various conventional sampling methods in this field. Atmospheric particulate matter sampling filter membrane can be PM2.5 filter membrane, the general diameter is 47cm.

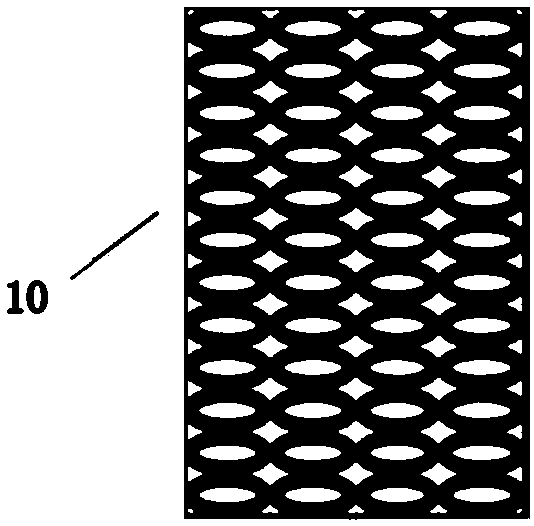

[0048] 2. Put the atmospheric particulate matter sampling filter membrane 4 into the membrane holder assembly tray 10 . The collected air particulate matter sampling filter membranes can be arranged in order on the membrane holder assembly plate 10, and each groove corresponds to a membrane 2 to be tested.

[0049] 3. Open the cabin door 3 below the mechanical arm, and utilize the automatic punching sampler 1 to cut out a membrane 2 to be measured of a predetermined size (such as 0.534 square centimeters) on the membrane. Meanwhile, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com