Graphite radiator and integral forming method thereof

A technology of integral molding and radiator, which is applied in the direction of indirect heat exchangers, heat exchange equipment, and other household appliances. It can solve the problems of small convective heat transfer coefficient, difficulty in integral molding, and poor heat dissipation effect, and achieve convective heat transfer. High coefficient, low production cost, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

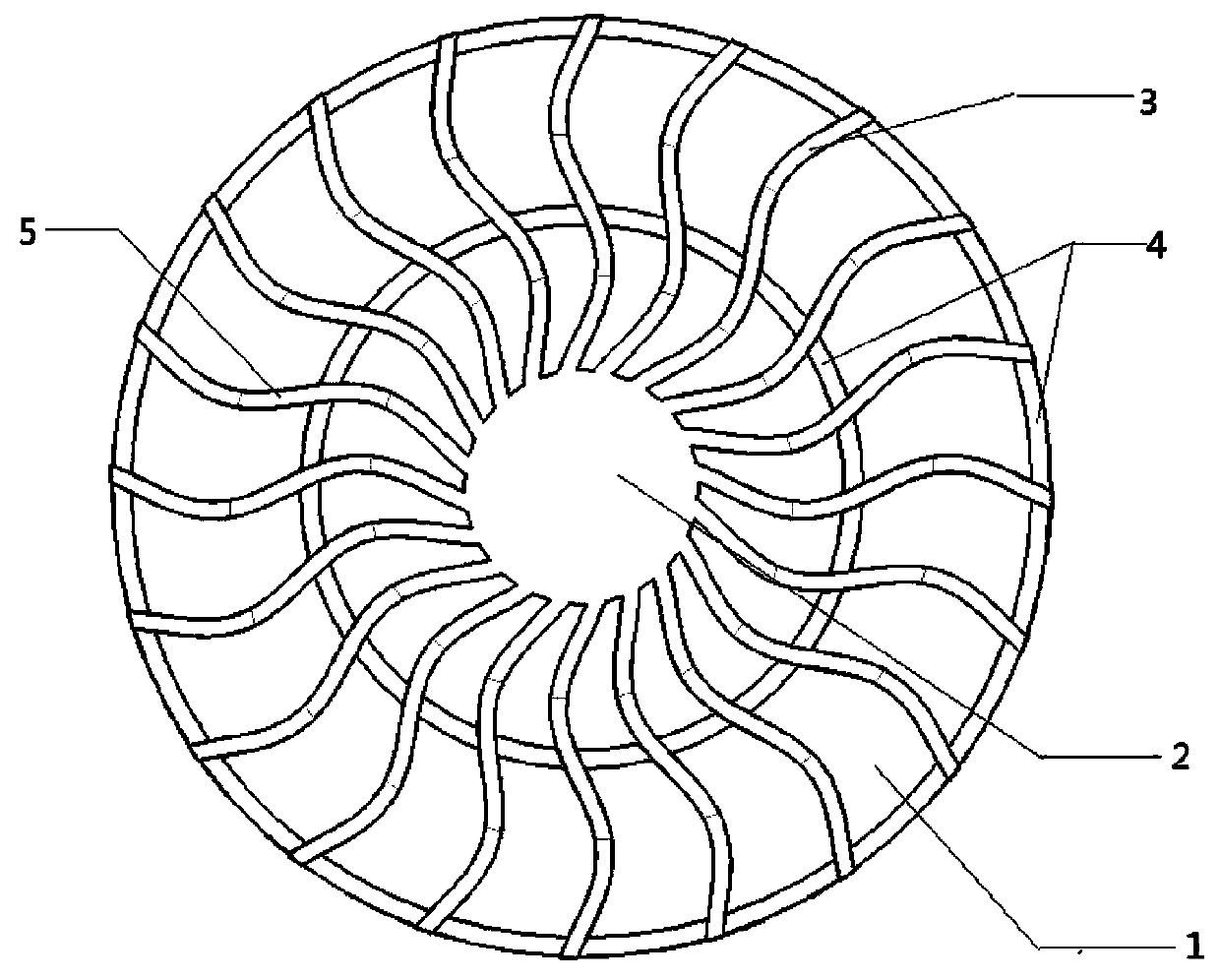

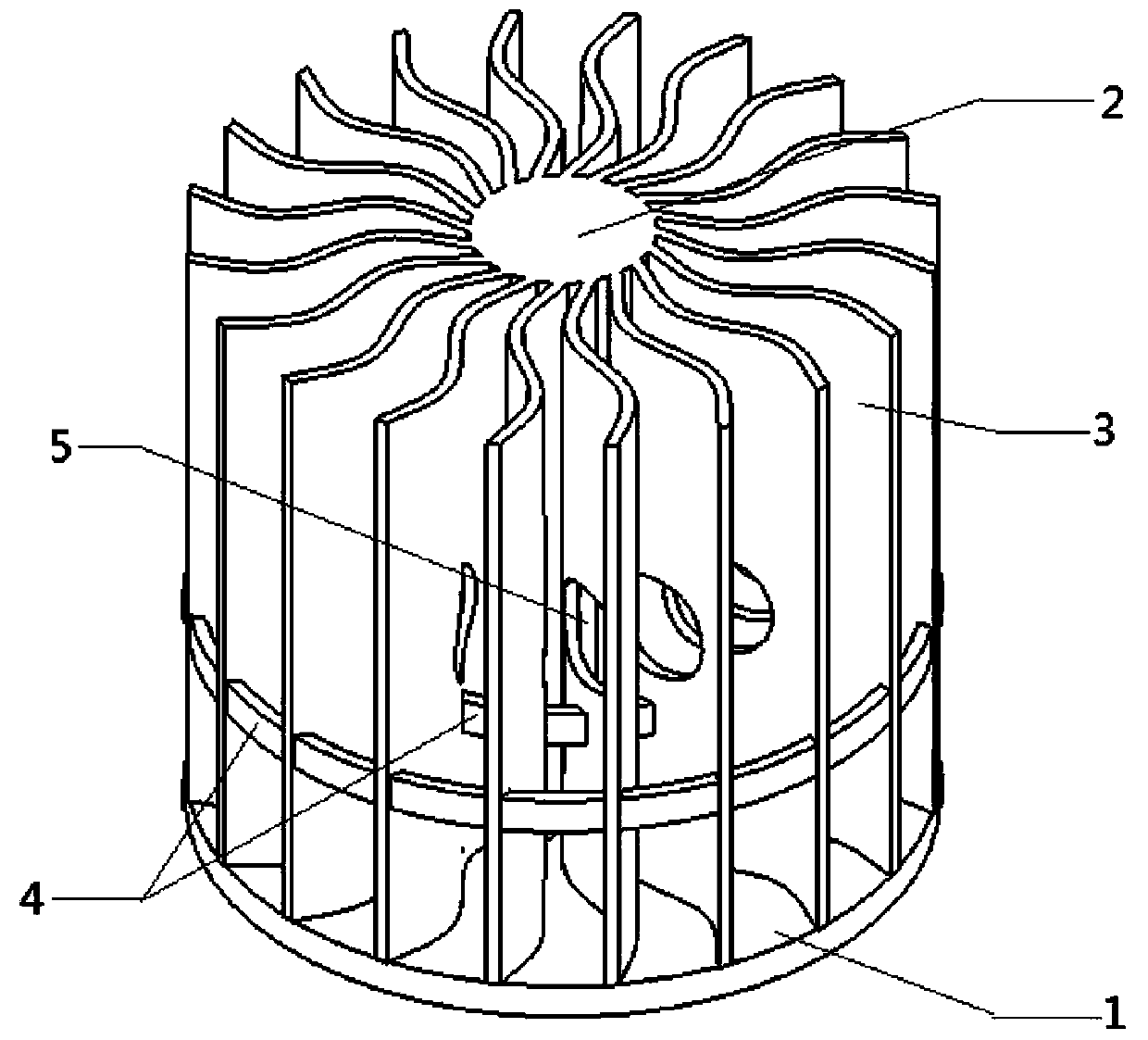

[0020] As shown in the figure, a graphite radiator provided in this embodiment includes a heat dissipation substrate 1, a thermal column 2, 20 heat dissipation fins 3 and 2 connecting ribs 4; the thermal column 2 is arranged at the center 1 of the heat dissipation substrate, 20 cooling fins 3 are radially distributed with the heat column 2 as the center. In order to improve the convective heat transfer coefficient, the above-mentioned cooling fins 3 are provided with small holes 5. In order to increase the cooling area, the cooling fins 3 are designed to be curved. At different radii in the circumferential direction of the graphite radiator, connecting ribs 4 are designed to connect the cooling fins 3 together to improve the overall rigidity. The specific dimensions of this embodiment are as follows: substrate diameter 40mm, thickness 2mm; heat column diameter 10mm, height 35mm; 0.8mm. Compared with the general straight fin structure, the heat dissipation area of this struc...

Embodiment 2

[0028] As shown in the figure, the present invention provides a graphite heat sink, comprising a heat dissipation substrate 1, a thermal column 2, 15 heat dissipation fins 3 and 2 connecting ribs 4; The column 2 is the center and 15 heat dissipation fins 3 are distributed radially. In order to improve the convective heat transfer coefficient, the above heat dissipation fins 3 are provided with small holes 5. In order to increase the heat dissipation area, the heat dissipation fins 3 are designed as a curved surface to dissipate heat along the graphite. At different radii in the circumferential direction of the device, connecting ribs 4 are designed to connect the cooling fins 3 together to improve the overall rigidity. The specific dimensions of this embodiment are as follows: substrate diameter 40mm, thickness 2mm; heat column diameter 10mm, height 35mm; 0.8mm. Compared with the general straight fin structure, this structure increases the heat dissipation area by 6.4%.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com