Extractor hood

A range hood and fan technology, applied in the field of range hoods, can solve the problems of easy blockage of the mesh, not convenient and simple, and limited grease separation effect, and achieve the effects of improving grease separation, reducing pollution, and good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

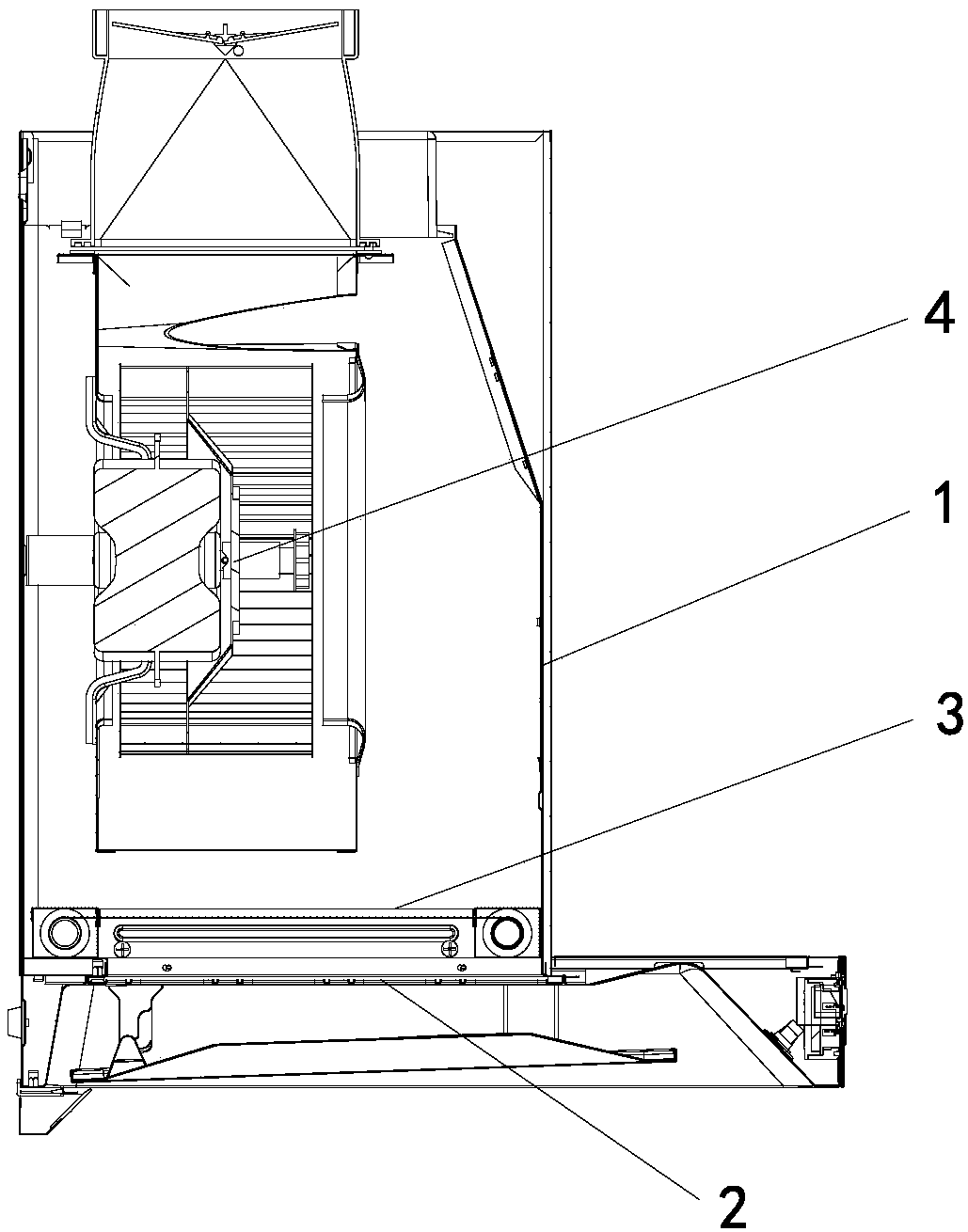

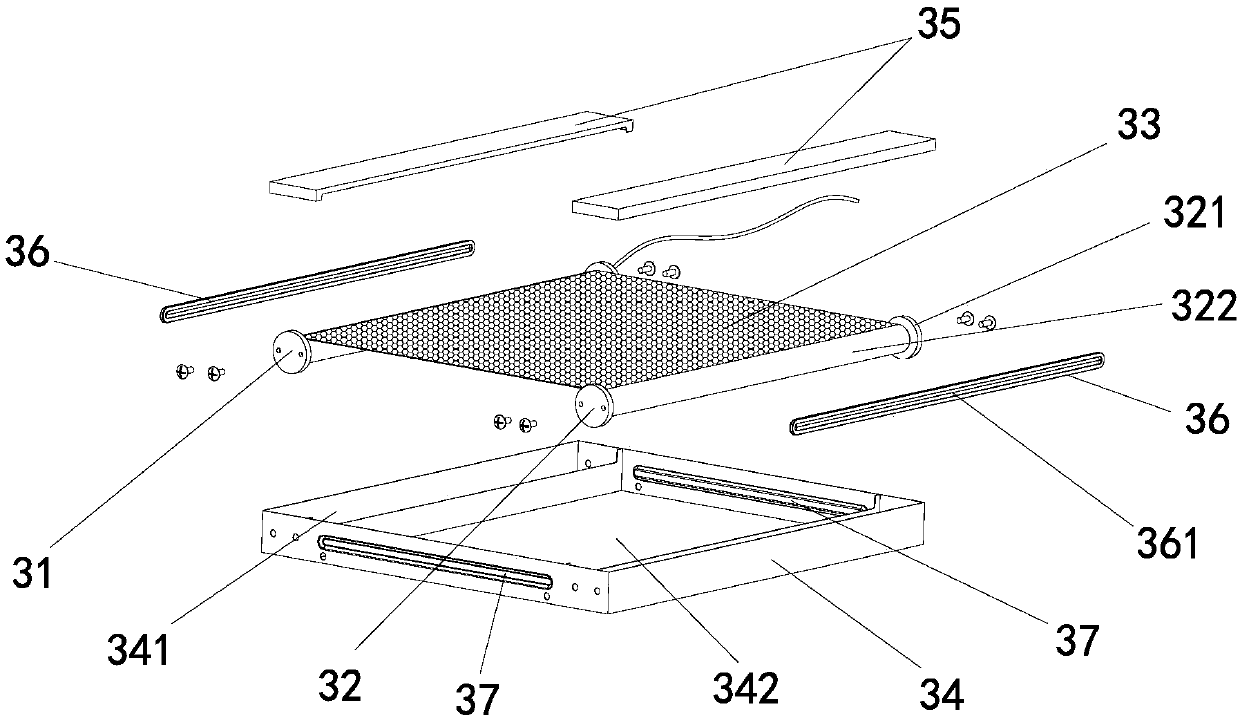

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that in this embodiment, the roller filter assembly 3 is applied to a side-suction range hood, the side-suction range hood is provided with an inclined smoke collection hood, and the smoke collection hood is provided with There is an installation plane for installing the roller filter assembly, and the roller filter assembly 3 is installed on the installation plane of the smoke collection hood; the air inlet 51 can be designed as a square, circular or other shapes, and the roller filter assembly 3 is installed At the front end of the air inlet, that is, the roller filter assembly 3 is installed on the outside of the installation plane of the smoke collecting hood. When the range hood smokes, the oil fume first passes through the flexible filter material 33 and then flows into the housing through the air inlet. In the example, since the air inlet is located at the rear end of the air inlet of the roller filter ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com