Crystal-guiding and impurity-removal device and method for preparing high-purity alumina polycrystals by virtue of cold crucible

A high-purity alumina and cold crucible technology, applied in chemical instruments and methods, crystal growth, polycrystalline material growth, etc., can solve the problems affecting the quality of sapphire single crystal, the decrease of the purity of alumina polycrystal, and the pollution of alumina polycrystal , to achieve the effect of saving manpower and material resources, simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

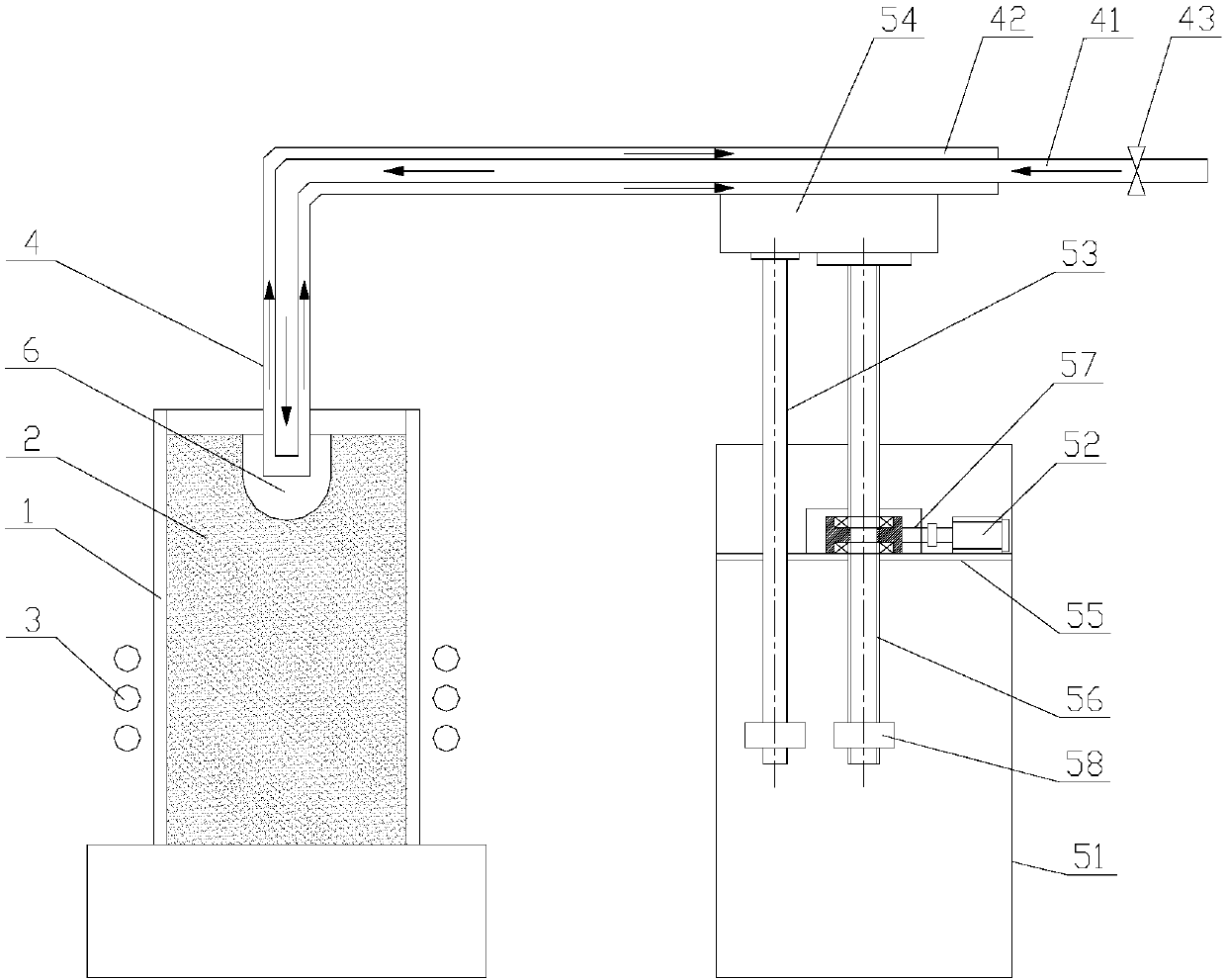

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0026] see figure 1 , a seeding and impurity removal device for preparing high-purity alumina polycrystals in a cold crucible, comprising a cold crucible 1 equipped with a high-purity alumina melt 2, an electromagnetic induction coil 3 arranged along the circumference of the cold crucible 1, a double Layer water-cooled copper pipe 4 and lifting system, the inner layer of double-layer water-cooled copper pipe 4 is water inlet pipe 41, the outer layer is water outlet pipe 42, the end of water inlet pipe communicates with the water outlet pipe, and the water inlet end of water inlet pipe 41 is provided with a flow rate The regulating valve 43, the water inlet and outlet of the double-layer water-cooled copper pipe are connected with the circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com