PPS-rare earth permanent-magnetic granular master batch used for injection molding and preparation method of same

A rare earth permanent magnet and rare earth magnetic powder technology, which is applied in the field of PPS-rare earth permanent magnet injection particle masterbatch and its preparation field, can solve the problem that it is difficult for the injection molding products of magnetic devices to meet the material requirements, improve the uniformity and stability, prevent the Magnetic powder oxidation, the effect of high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

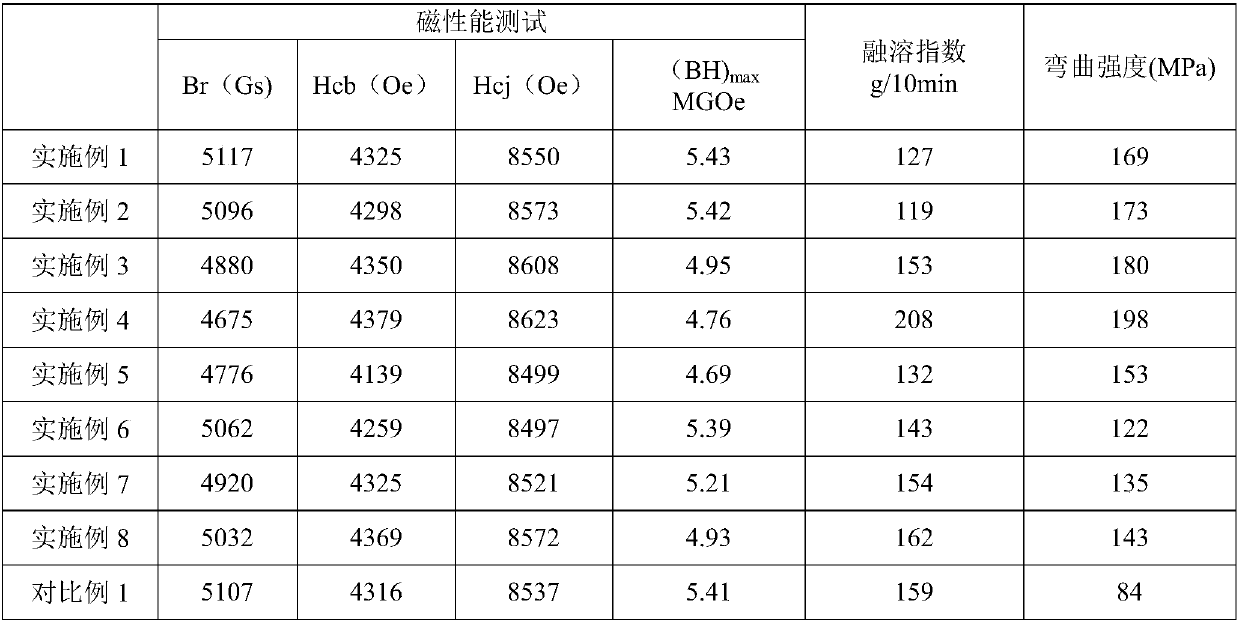

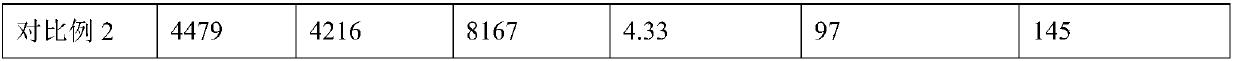

Examples

Embodiment 1

[0030] A PPS-rare earth permanent magnet injection molding particle masterbatch, comprising the following raw materials in weight percentages:

[0031] 91 parts of rare earth magnetic powder, 6.1 parts of PPS powder, 1.5 parts of reinforcing agent, 0.5 parts of coupling agent, 0.5 parts of antioxidant, 0.4 parts of lubricant;

[0032] Among them, the rare earth magnetic powder is isotropic NdFeB magnetic powder, the reinforcing agent is glass fiber, the coupling agent is silane coupling agent, the antioxidant is phosphoric acid, and the lubricant is N,N'-ethylene bisstearamide.

[0033] The preparation method of PPS-rare earth permanent magnet injection molding particle masterbatch comprises the following steps:

[0034] a) Surface treatment of magnetic powder: Add antioxidant to rare earth magnetic powder and blend for 30 minutes at 100°C to obtain surface-treated magnetic powder; dissolve antioxidant in absolute ethanol before use, and the mass ratio of antioxidant to absolu...

Embodiment 2

[0041] A PPS-rare earth permanent magnet injection molding particle masterbatch, comprising the following raw materials in weight percentages:

[0042] 91 parts of rare earth magnetic powder, 6.1 parts of PPS powder, 1.5 parts of reinforcing agent, 0.5 parts of coupling agent, 0.5 parts of antioxidant, 0.4 parts of lubricant;

[0043] Among them, the rare earth magnetic powder is isotropic NdFeB magnetic powder, the reinforcing agent is carbon fiber, the coupling agent is silane ester coupling agent, the antioxidant is phosphoric acid, and the lubricant is N,N'-ethylene bisstearamide.

[0044] The preparation method of the PPS-rare earth permanent magnet injection molding particle masterbatch is the same as in Example 1.

Embodiment 3

[0046] A PPS-rare earth permanent magnet injection molding particle masterbatch, comprising the following raw materials in weight percentages:

[0047] 88 parts of rare earth magnetic powder, 7.2 parts of PPS powder, 2.4 parts of reinforcing agent, 0.5 part of coupling agent, 0.5 part of antioxidant, 0.4 part of lubricant;

[0048] Among them, the rare earth magnetic powder is isotropic NdFeB magnetic powder, the reinforcing agent is glass fiber, the coupling agent is silane ester coupling agent, the antioxidant is phosphoric acid, and the lubricant is N,N'-ethylene bisstearamide.

[0049] The preparation method of the PPS-rare earth permanent magnet injection molding particle masterbatch is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com