Automatic wire feeding device with fault self-diagnostic function and diagnostic method

A wire feeding device and self-diagnosis technology, which is used in the transportation of filamentous materials, transportation and packaging, and thin material handling, etc. The effect of design and circuit design simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

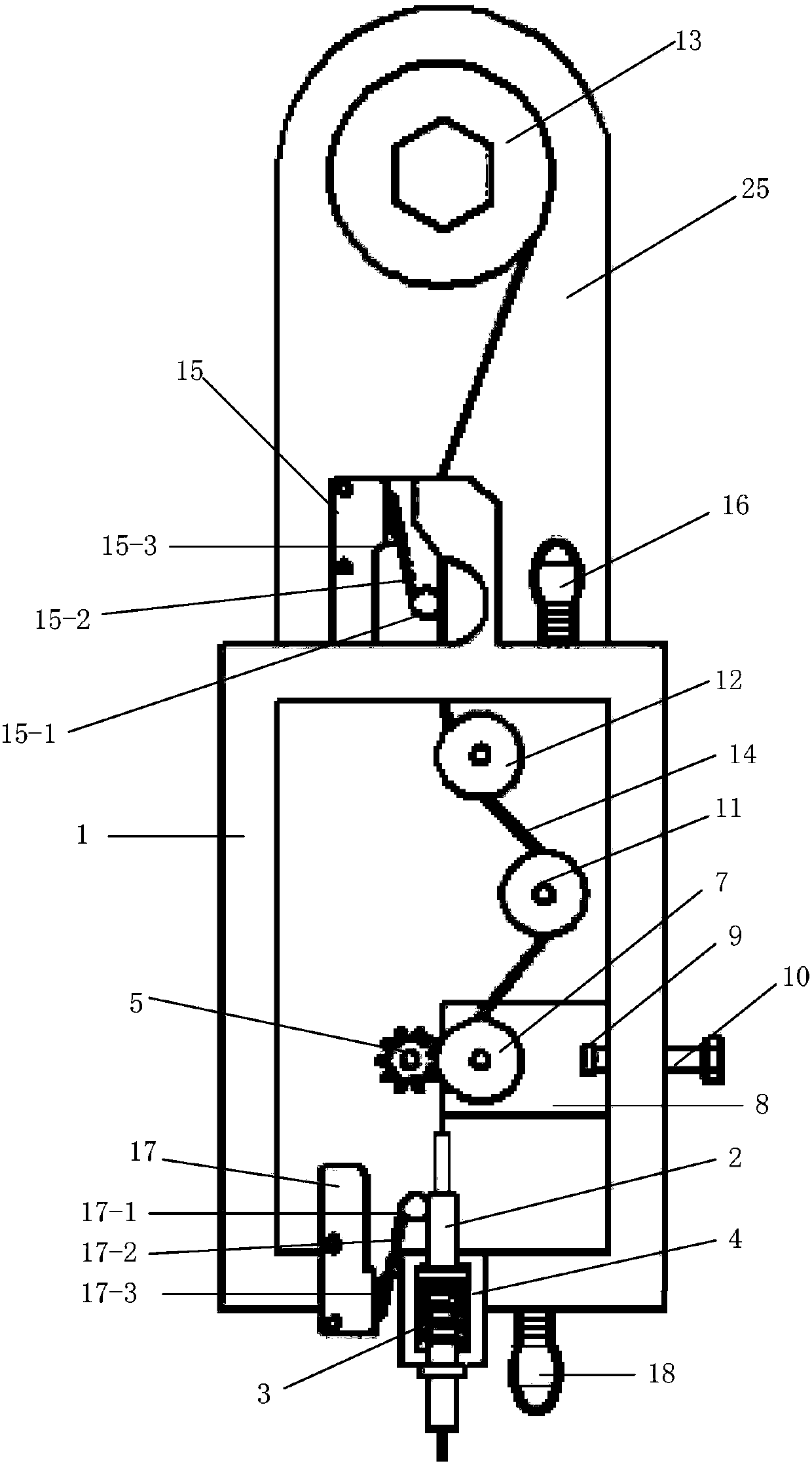

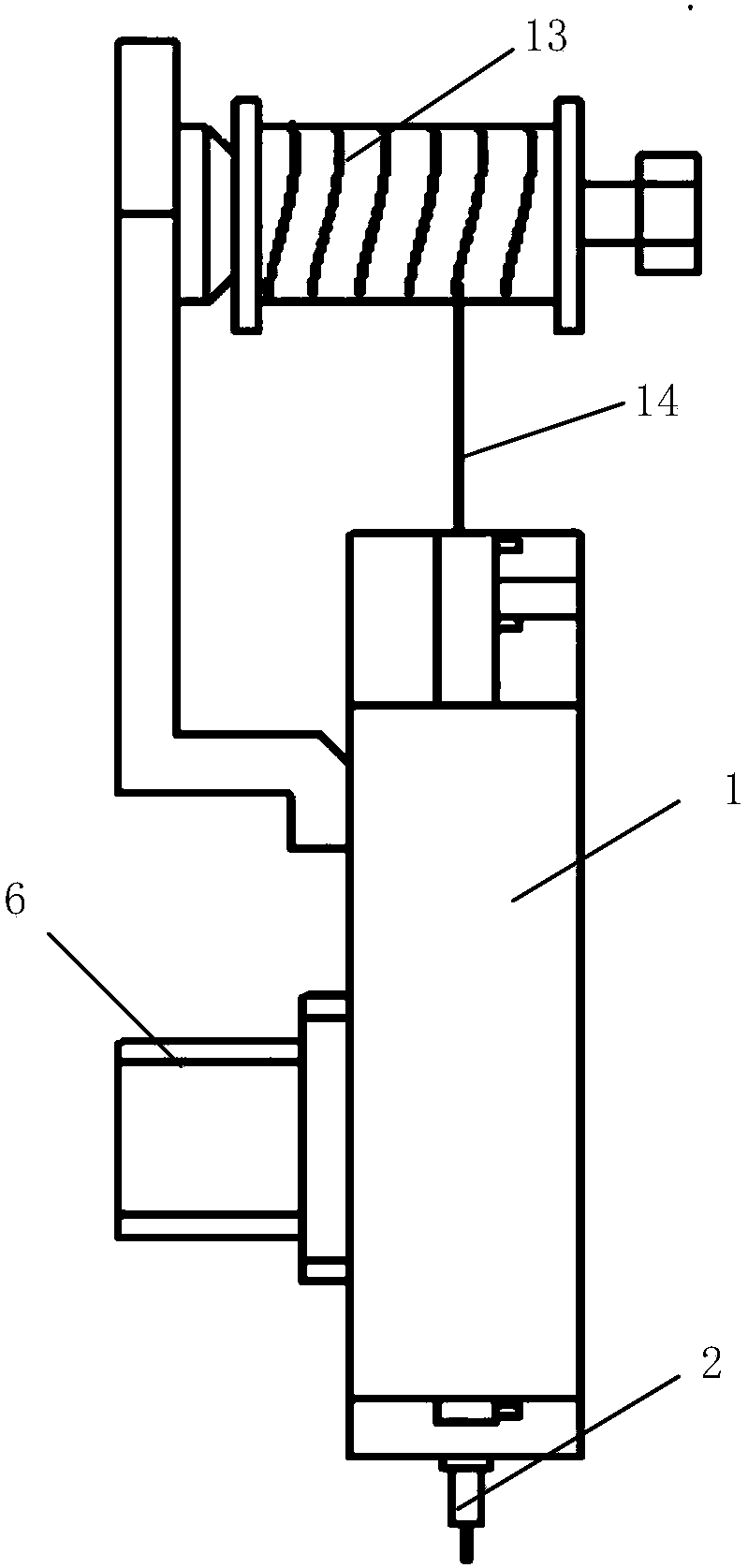

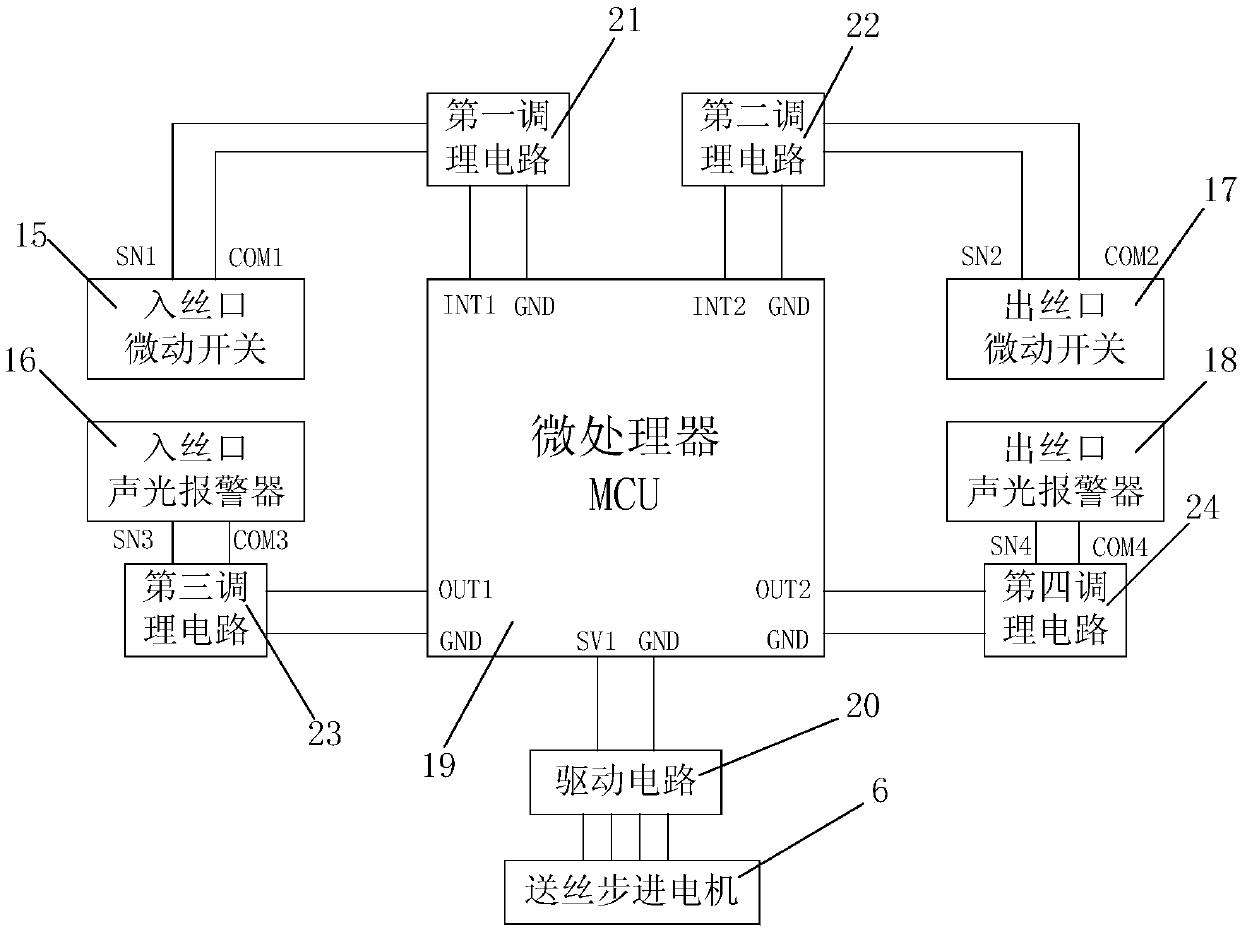

[0032] Such as figure 1 , figure 2 , image 3 As shown, the present invention provides an automatic wire feeding device with a fault self-diagnosis function, which includes an automatic wire feeding device, an alarm device, and a control unit.

[0033]The automatic wire feeding device includes a base 1, a wire feeding catheter 2, a spring 3, a spring fixing cavity 4, a gear 5, a wire feeding stepping motor 6, a driven wheel 7, a movable bottom plate 8, a beam 9, and elongated bolts 10. The first auxiliary wheel 11 , the second auxiliary wheel 12 , the bracket 25 and the reel 13 .

[0034] Further, the wire feeding catheter 2 is a hollow tube with a thin upper end and a thicker lower end, the spring 3 is sleeved on the middle end of the wire feeding catheter 2 , the two are relatively fixed, and are installed in the spring fixing cavity 4 Inside, the spring fixing cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com