Device and method for improving working frequency of lamp pump laser amplifiers

A laser amplifier, working frequency technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of complex mechanical design, cumbersome wheel-type device, high cost, simplify mechanical design, reduce mechanical devices, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

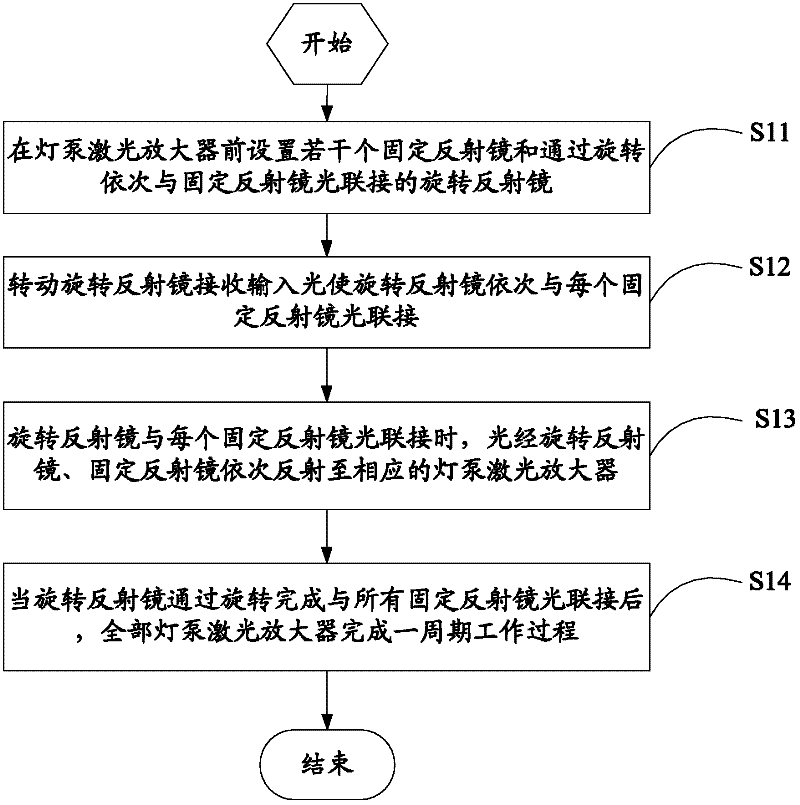

[0034] A device for improving the operating frequency of a lamp-pumped laser amplifier proposed in the following embodiments of the present invention includes several lamp-pumped laser amplifiers and reflectors, and through the mutual cooperation of the reflectors, light enters different lamp-pumped laser amplifiers to increase the operating frequency .

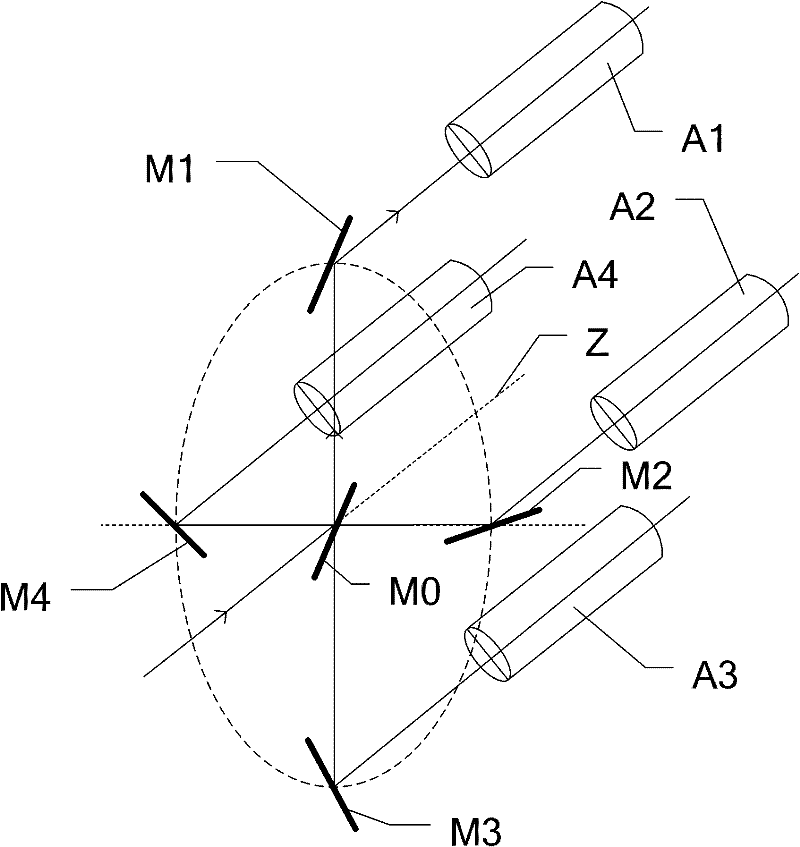

[0035] figure 1 It is a schematic structural diagram of the device described in Embodiment 1 of the present invention, including:

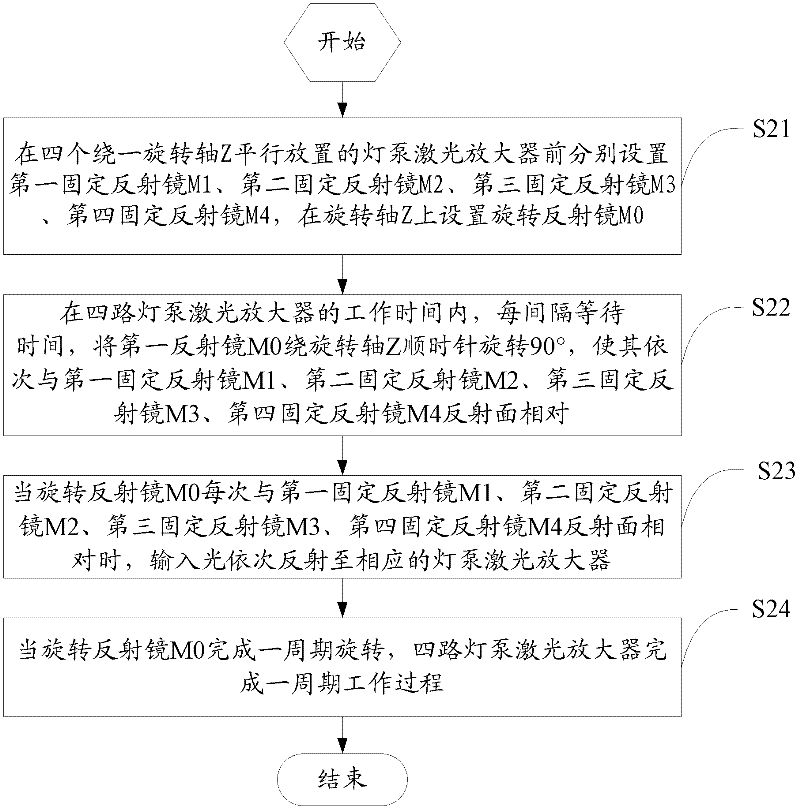

[0036] Four lamp-pumped laser amplifiers placed in parallel around the rotation axis Z: the first lamp-pumped laser amplifier A1 (hereinafter referred to as A1), the second lamp-pumped laser amplifier A2 (hereinafter referred to as A2), the third lamp-pumped laser amplifier A3 (hereinafter referred to as A3), the fourth lamp-pumped laser amplifier A4 (hereinafter referred to as A4).

[0037] Four fixed mirrors: the first fixed mirror M1 (hereinafter referred to as M1), the second fixed mirror M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com