A kind of preparation method of graphene and titanium alloy composite powder ball milling

A composite powder and titanium alloy technology, which is applied in the field of powder titanium alloy materials, can solve the problems that graphene is difficult to uniformly disperse and interface bonding is not good, and achieve the effects of improving interface bonding, avoiding over-temperature oxidation, and controlling precise process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

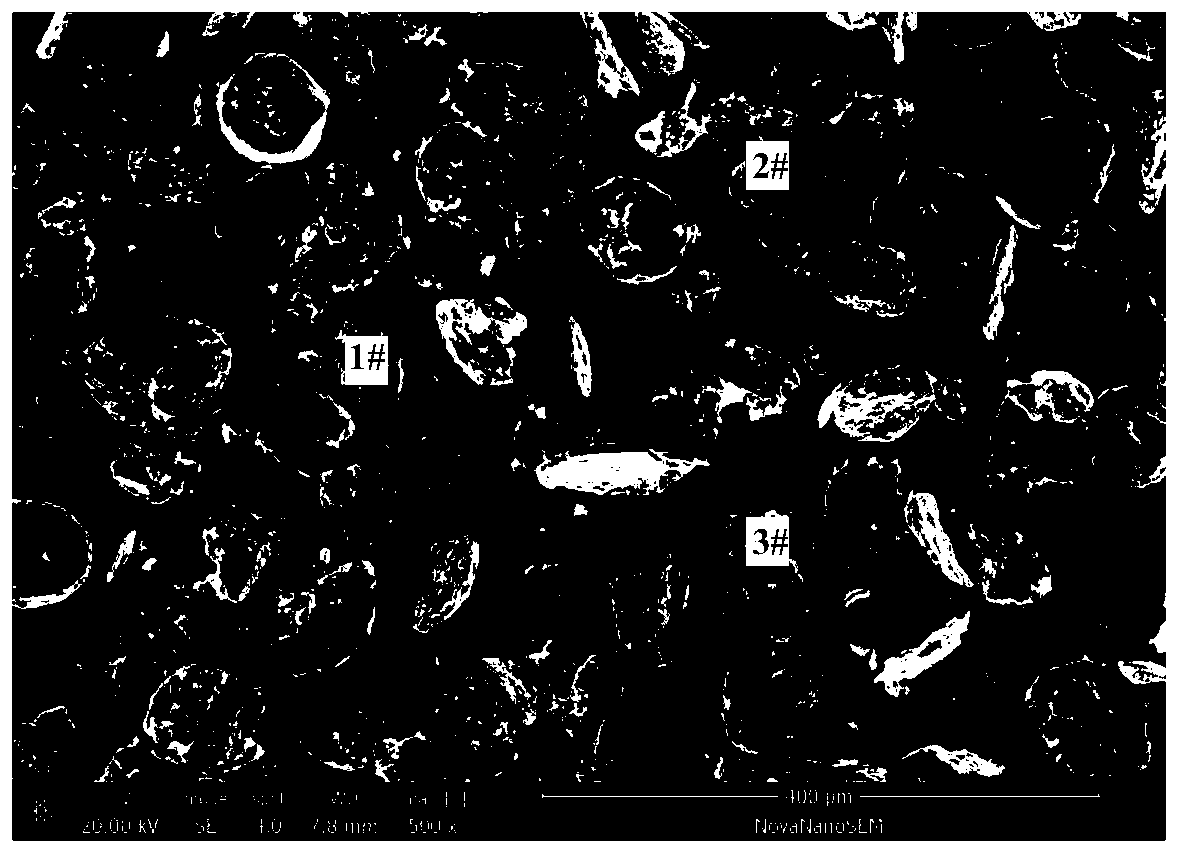

Image

Examples

preparation example Construction

[0023] The preparation method comprises the following steps:

[0024] (1) Accurately weigh 0.1% to 10% of the mass of titanium alloy powder and add graphene oxide nanosheets into a beaker filled with absolute ethanol. The accuracy of the electronic balance is 0.01g; use a high-speed mechanical stirrer to stir, the stirrer The working time is 20min to 30min, the speed is 4000r / min to 6000r / min, and then ultrasonic dispersion treatment is carried out with an ultrasonic cell pulverizer to prepare a solution with relatively uniform dispersion of graphene oxide. The working time of the ultrasonic cell pulverizer is 30min to 40min, The working frequency is vibration 2s, gap 3s;

[0025] (2) Mix the titanium alloy powder with relatively uniform particle size and the graphene oxide solution obtained in step (1) and put it into the quantitative agate ball milling tank of the omnidirectional planetary ball milling equipment, and add an appropriate amount of absolute ethanol to the ball ...

Embodiment 1

[0034] Add 5.0 g of feathery, translucent graphene oxide nanosheets prepared by the redox method to a beaker of 500 ml of absolute ethanol, and stir with a high-speed mechanical stirrer. The stirring time is 20 min, and the rotation speed is 5000 r / min, and then use an ultrasonic cell pulverizer to carry out ultrasonic dispersion treatment to prepare a solution with relatively uniform dispersion of graphene oxide. The working time of the ultrasonic cell pulverizer is 40min.

[0035] Mix 995g of titanium alloy powder with a particle size of 53 μm to 106 μm with the above-mentioned graphene oxide solution and put it into the quantitative agate ball milling tank of the omnidirectional planetary ball milling equipment, and add an appropriate amount of absolute ethanol to the ball milling tank to make the balls and materials The total volume with absolute ethanol is less than 2 / 3 of the volume of the ball milling tank. After sealing, open the ball milling equipment for ball milling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com