Preparation method of bacterium-sensitive intelligent antibacterial coating and application

An antibacterial coating, intelligent technology, applied in the field of intelligent antibacterial coating and its application in orthopedic implants, and the preparation of antibacterial coating, can solve the problem of not taking into account the problem of bacterial drug resistance, and achieve the reduction of bacterial Possibility of drug resistance, increased sensitivity, and wide-ranging bactericidal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

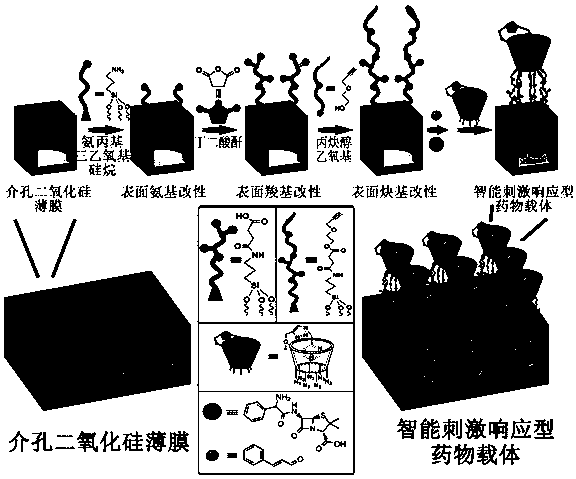

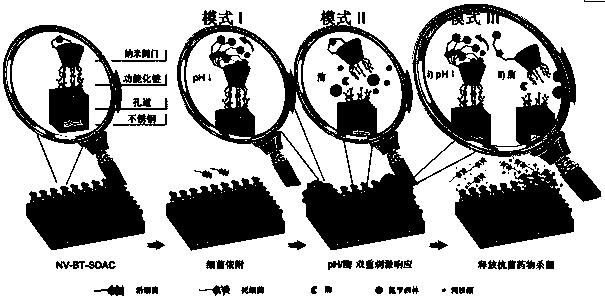

[0041] Bacteria-sensitive intelligent antibacterial coating of the present invention, the steps are as follows:

[0042] 1. Preparation of Mesoporous Silica Films

[0043] First, configure the precursor solution: 80 μL of tetraethyl orthosilicate, 0.16 g of cetyltrimethylammonium bromide, 30 mL of ethanol, 70 mL of deionized water, 10 μL of ammonia water; secondly, 316L stainless steel (1×0.5cm 2 ) immersed in the precursor solution at 60°C for 15 days; finally, the sample was taken out, washed with an ethanol solution containing HCl (0.83mL 37wt% hydrochloric acid dissolved in 100mL ethanol), deionized water, and dried to obtain a silica film.

[0044] 2. Modification of Mesoporous Silica Film Surface with Functional Groups

[0045] Preparation of amino-modified film: Place the dried silica film on a copper grid in a flask, immerse in anhydrous toluene (5 mL), add aminopropyltriethoxysilane (20 μL / cm 2 , cm in the present invention 2 is the area of stainless steel), he...

Embodiment 2

[0055] Bacteria-sensitive intelligent antibacterial coating of the present invention, the steps are as follows:

[0056] 1. Preparation of Mesoporous Silica Films

[0057] First, configure the precursor solution: 80 μL of tetraethyl orthosilicate, 0.16 g of cetyltrimethylammonium bromide, 30 mL of ethanol, 70 mL of deionized water, 10 μL of ammonia water; secondly, 316L stainless steel (1×0.5cm 2 ) was immersed in the precursor solution at 58°C for 20 days; finally, the sample was taken out, washed with an ethanol solution containing HCl (0.83mL 37wt% hydrochloric acid dissolved in 100mL ethanol), deionized water, and dried to obtain a silica film.

[0058] 2. Modification of Mesoporous Silica Film Surface with Functional Groups

[0059] Preparation of amino-modified film: Place the dried silica film on a copper grid in a flask, immerse in anhydrous toluene (5 mL), add aminopropyltriethoxysilane (20 μL / cm 2 ), heated to reflux, and stirred for 24 h. After the reaction, the...

Embodiment 3

[0069] Bacteria-sensitive intelligent antibacterial coating of the present invention, the steps are as follows:

[0070] 1. Preparation of Mesoporous Silica Films

[0071] First, configure the precursor solution: 80 μL of tetraethyl orthosilicate, 0.16 g of cetyltrimethylammonium bromide, 30 mL of ethanol, 70 mL of deionized water, 10 μL of ammonia water; secondly, 316L stainless steel (1×0.5cm 2 ) immersed in the precursor solution at 62°C for 15 days; finally, the sample was taken out, washed with an ethanol solution containing HCl (0.83mL 37wt% hydrochloric acid dissolved in 100mL ethanol), deionized water, and dried to obtain a silica film.

[0072] 2. Modification of Mesoporous Silica Film Surface with Functional Groups

[0073] Preparation of amino-modified film: Place the dried silica film on a copper grid in a flask, immerse in anhydrous toluene (5 mL), add aminopropyltriethoxysilane (20 μL / cm 2 ), heated to reflux, and stirred for 24 h. After the reaction, the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com