Glass fiber reinforced plastic round bar applied to lightweight all-dielectric aerial optical cable

A glass fiber and reinforced plastic technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of poor bending performance, large weight and limited effect of optical cables, increase the ability to withstand external force damage, and enhance tensile, compressive and impact resistance. , strength and hardness corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

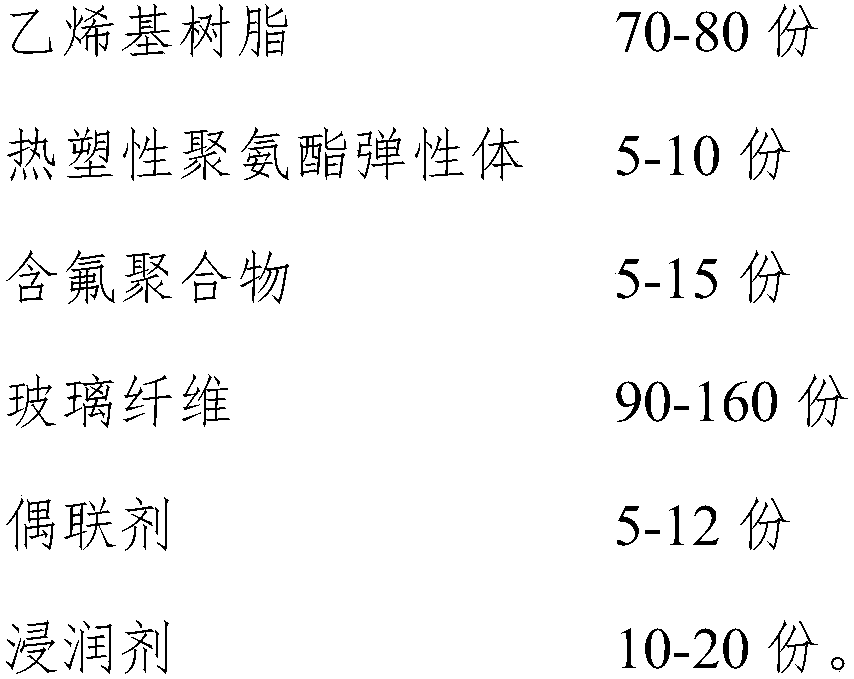

[0034] Embodiment 1 discloses a glass fiber reinforced plastic round rod material, as shown in Table 1, including the following components, in parts by weight:

[0035] Glass fiber material formula table in the embodiment 1 of table 1

[0036] components

Dosage (parts)

vinyl resin

70

thermoplastic polyurethane elastomer

5

5

glass fiber

90

coupling agent

5

Wetting agent

10

[0037] Wherein, the wetting agent includes the following components: 60 parts of water-based polyurethane emulsion, 40 parts of epoxy siloxane coupling agent or 40 parts of hyperbranched high molecular weight epoxy siloxane coupling agent.

[0038] The fluorine-containing polymer includes one or more of the following: PVDF, FEP, ETFE.

[0039] The thermoplastic polyurethane elastomer includes one or more of the following: polyvinylidene fluoride, thermoplastic polyurethane, polypropylene copolymer, polyolefin-rubber...

Embodiment 2

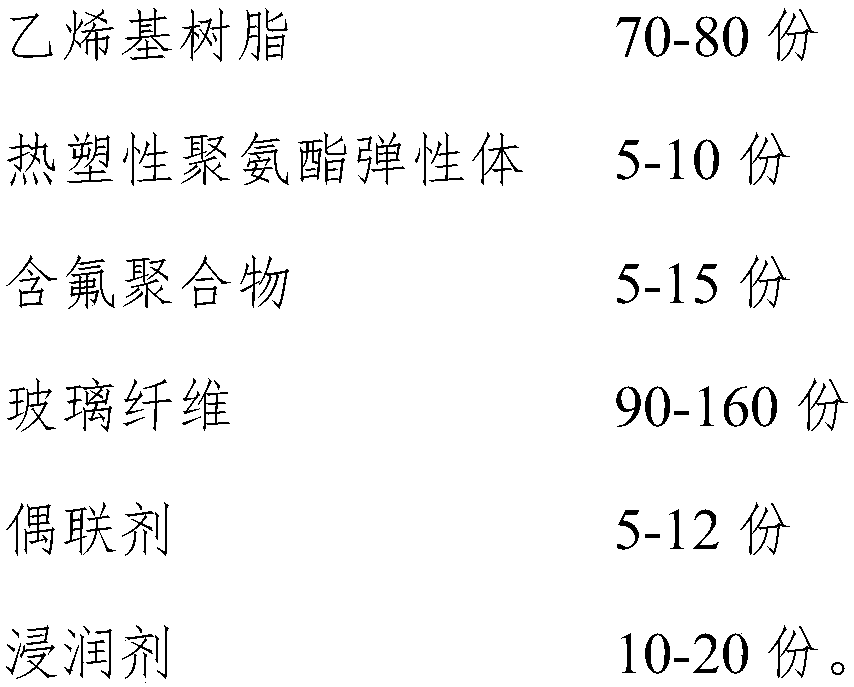

[0050] Embodiment 2 discloses a glass fiber reinforced plastic round rod material, as shown in Table 2, including the following components, in parts by weight:

[0051] Glass fiber material formula table in the embodiment 2 of table 2

[0052] components

Dosage (parts)

vinyl resin

75

thermoplastic polyurethane elastomer

8

12

glass fiber

125

coupling agent

7

Wetting agent

15

[0053] Wherein, the wetting agent includes the following components: 65 parts of water-based polyurethane emulsion, 35 parts of epoxy siloxane coupling agent or 35 parts of hyperbranched high molecular weight epoxy siloxane coupling agent.

[0054] The fluorine-containing polymer includes one or more of the following: PVDF, FEP, ETFE.

[0055] The thermoplastic polyurethane elastomer includes one or more of the following: polyvinylidene fluoride, thermoplastic polyurethane, polypropylene copolymer, polyolefin-rubb...

Embodiment 3

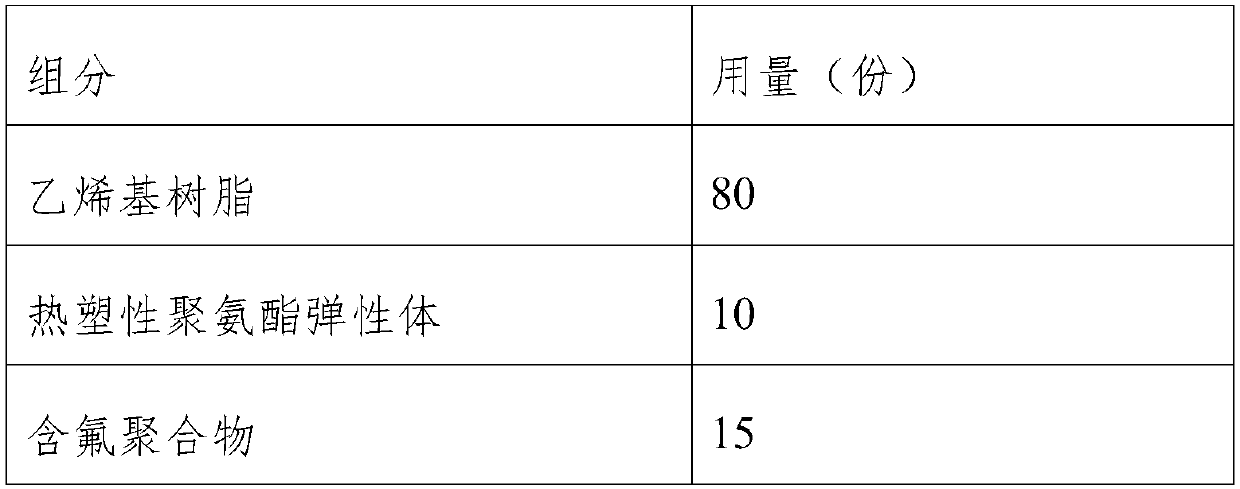

[0065] Embodiment 3 discloses a glass fiber reinforced plastic round rod material, as shown in Table 3, including the following components, in parts by weight:

[0066] Glass fiber material formula table in the embodiment 3 of table 3

[0067] components

Dosage (parts)

vinyl resin

80

thermoplastic polyurethane elastomer

10

15

glass fiber

160

coupling agent

12

Wetting agent

20

[0068] Wherein, the wetting agent includes the following components: 70 parts of water-based polyurethane emulsion, 30 parts of epoxy siloxane coupling agent or 30 parts of hyperbranched high molecular weight epoxy siloxane coupling agent.

[0069] The fluorine-containing polymer includes one or more of the following: PVDF, FEP, ETFE.

[0070] The thermoplastic polyurethane elastomer includes one or more of the following: polyvinylidene fluoride, thermoplastic polyurethane, polypropylene copolymer, polyolefin-ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com