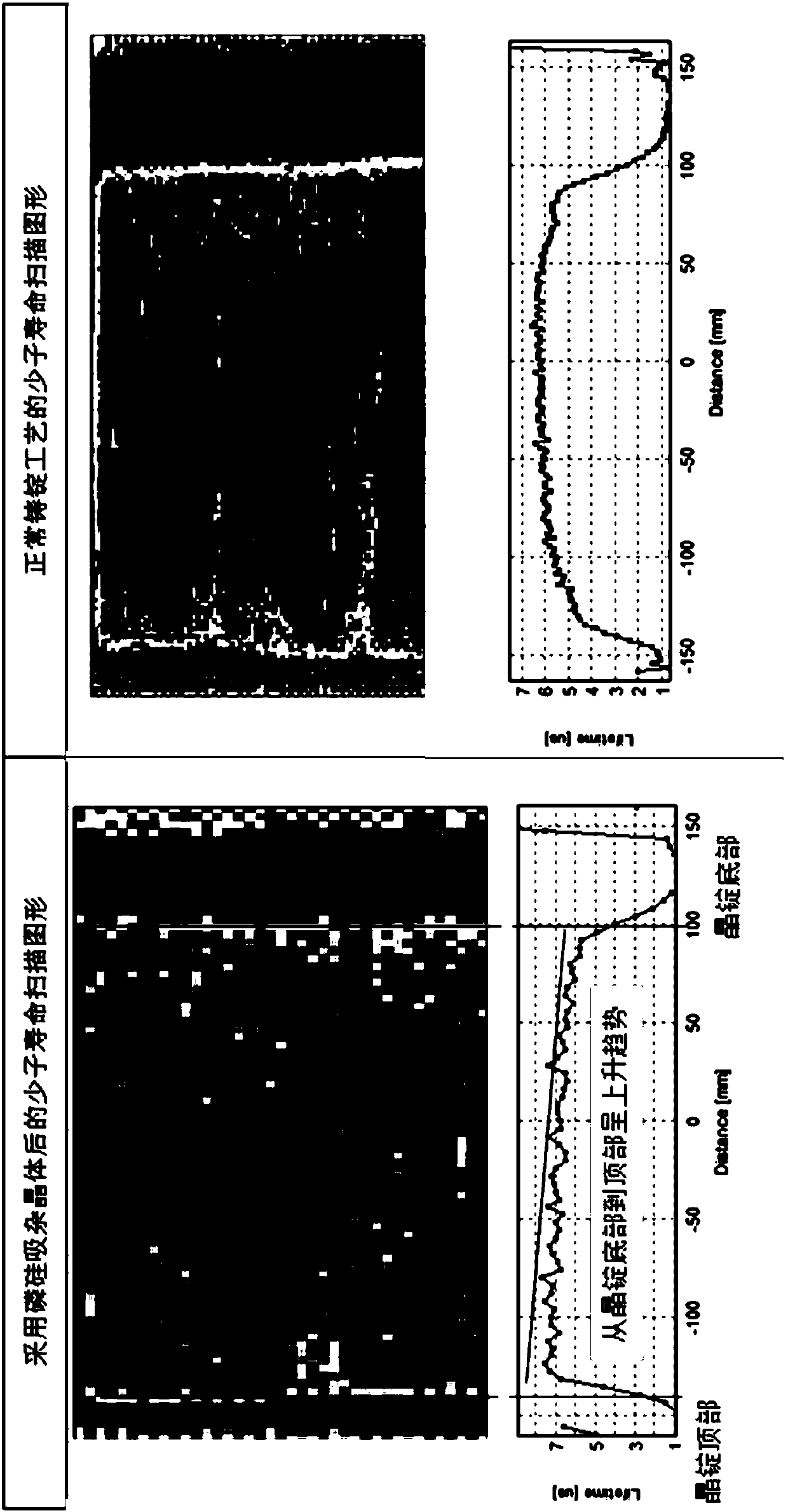

Method for increasing minority carrier lifetime of top of silicon ingot by gettering

A minority carrier lifetime and silicon ingot technology, applied in chemical instruments and methods, diffusion/doping, polycrystalline material growth, etc., can solve the problems of lack of new and efficient methods, and achieve the effect of improving minority carrier lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

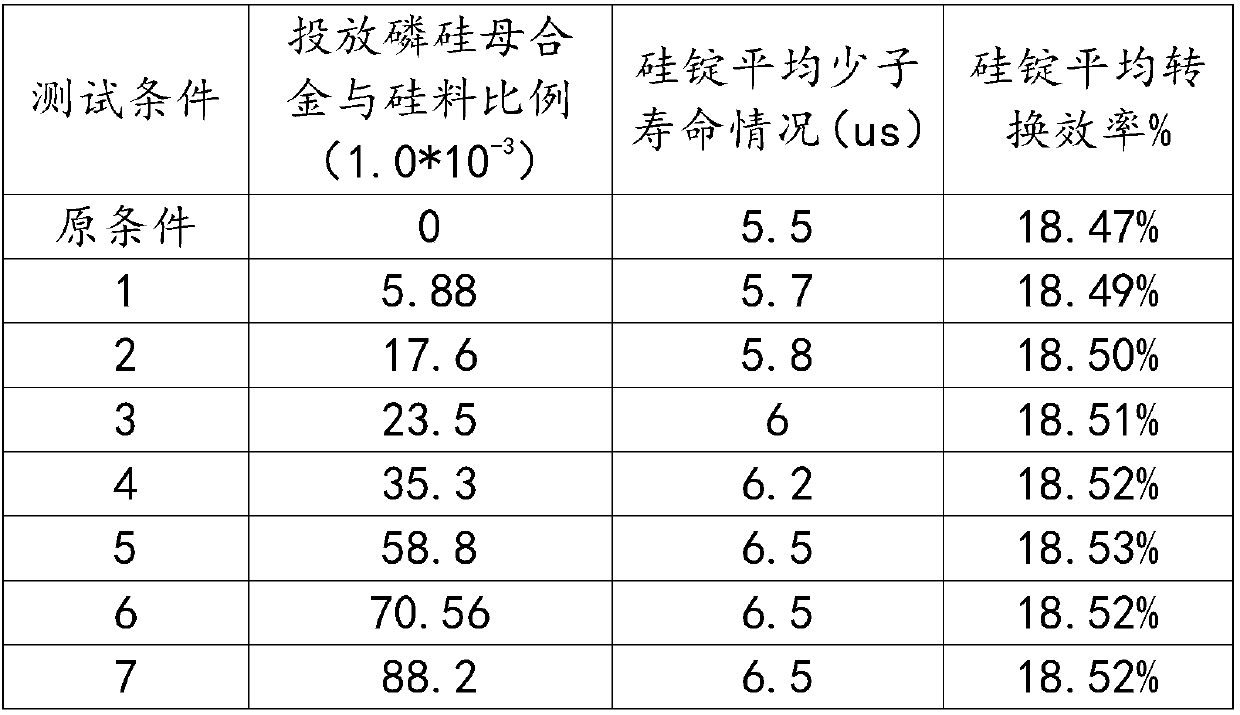

Embodiment 1

[0028] A method for increasing the minority carrier lifetime at the top of a silicon ingot by gettering, using the polycrystalline semi-melting process to cast the ingot, includes the following steps:

[0029] S1: Preparation of the polycrystalline furnace: Install the quartz rod on the upper part of the polycrystalline furnace, stretch the quartz rod to the bottom and mark it as zero, then raise the quartz rod, and install phosphorus weighing 20.34g in the argon gas pipeline Silicon master alloy. The phosphorus-silicon master alloy is obtained by diluting 100% phosphorus powder with 100% silicon by crystal pulling, and the size of the phosphorus-silicon master alloy is 1-15 mm. The resistivity of the phosphorus-silicon master alloy is greater than 0.0011Ω·cm. It is to convert the set target resistivity value into the gettering crystal concentration value according to the graphical method, table method or calculation method, so as to determine the input amount of the getterin...

Embodiment 2

[0038] A method for increasing the minority carrier lifetime at the top of a silicon ingot by gettering, using the polycrystalline semi-melting process to cast the ingot, includes the following steps:

[0039] S1: Preparation of the polycrystalline furnace: Install the quartz rod on the upper part of the polycrystalline furnace, stretch the quartz rod to the bottom and mark it as zero, then lift the quartz rod, and install phosphorus weighing 50.12g in the argon gas pipeline Silicon master alloy. The phosphorus-silicon master alloy is obtained by diluting 100% phosphorus powder with 100% silicon by crystal pulling, and the size of the phosphorus-silicon master alloy is 1-15 mm. The resistivity of the phosphorus-silicon master alloy is greater than 0.0011Ω·cm. It is to convert the set target resistivity value into the gettering crystal concentration value according to the graphical method, table method or calculation method, so as to determine the input amount of the gettering...

Embodiment 3

[0048] A method for increasing the minority carrier lifetime at the top of a silicon ingot by gettering, using the polycrystalline semi-melting process to cast the ingot, includes the following steps:

[0049] S1: Preparation of the polycrystalline furnace: Install the quartz rod on the upper part of the polycrystalline furnace, stretch the quartz rod to the bottom and mark it as zero, then raise the quartz rod, and install phosphorus with a weight of 12.04g in the argon gas pipeline Silicon master alloy. The phosphorus-silicon master alloy is obtained by diluting 100% phosphorus powder with 100% silicon by crystal pulling, and the size of the phosphorus-silicon master alloy is 1-15 mm. The resistivity of the phosphorus-silicon master alloy is greater than 0.0011Ω·cm. It is to convert the set target resistivity value into the gettering crystal concentration value according to the graphical method, table method or calculation method, so as to determine the input amount of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com