Conductive tool for container anodizing

An anodizing and containerized technology, applied in the direction of anodization, electrolysis process, electrolysis components, etc., can solve the problems affecting the popularization and use of container anodization, poor operation convenience, low processing efficiency, etc., achieving simple structure, simple operation, To ensure the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation, structure, features and functions of the packaged anodized conductive tool according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

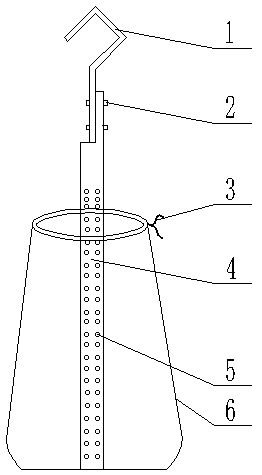

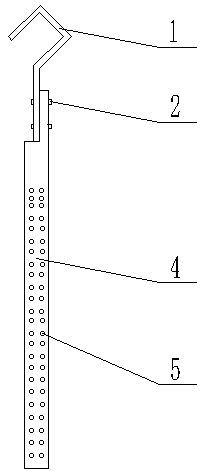

[0018] see Figure 1 to Figure 2 , the container anodized conductive tooling of the present invention includes a conductive rod 4, a container bag 6, and a rope 3 for fastening the bag mouth is provided at the mouth of the container bag 6, and is characterized in that: the middle of the container bag 6 A hollow conductive rod 4 is installed, the hook 1 is connected to the top of the conductive rod 4, and a plurality of cold-cut holes 5 are arranged on the conductive rod 4. The cold cut holes 5 are evenly arranged on the side of the conductive rod 4 . The hook 1 is connected with the conductive rod 4 through the fixing bolt 2 . Container bag 6 is soft nylon mesh bag. Rope 3 is a nylon rope. Hook 1 is a copper hook. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com