Stability-improved powdery metal degreasing agent

A metal degreasing and stable technology, applied in the field of metal surface cleaning, can solve the problems of increased cost of packaging, storage and transportation, poor alkali resistance of surfactants, limited content of active ingredients, etc., and achieves strong emulsification of oil pollution and easy operation , the effect of reducing production costs

Inactive Publication Date: 2018-01-16

合肥普庆新材料科技有限公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, most of the metal degreasing agents on the market are liquid products, and the content of active ingredients is limited, which increases the cost of packaging, storage and transportation.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

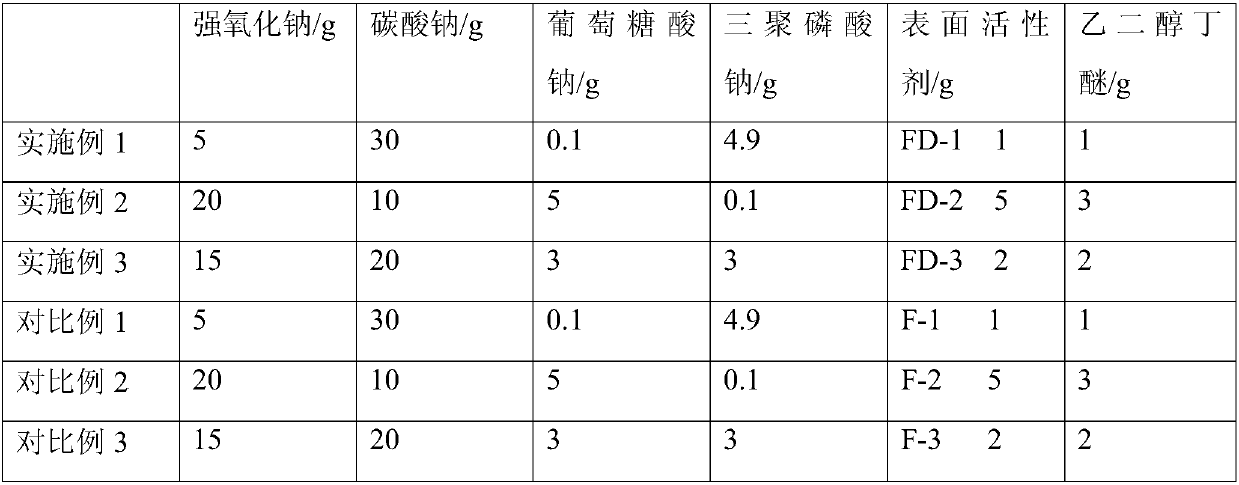

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

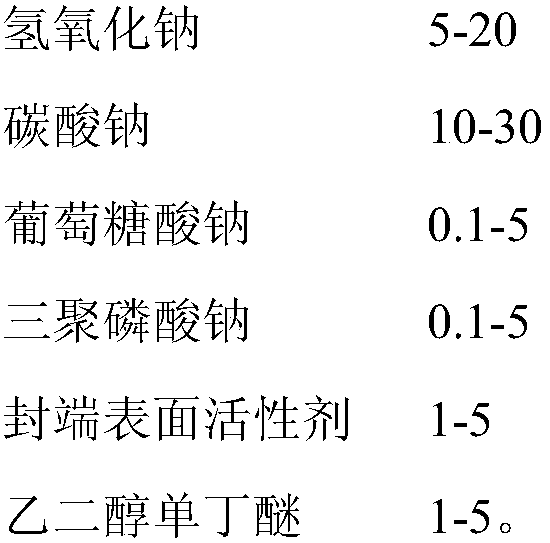

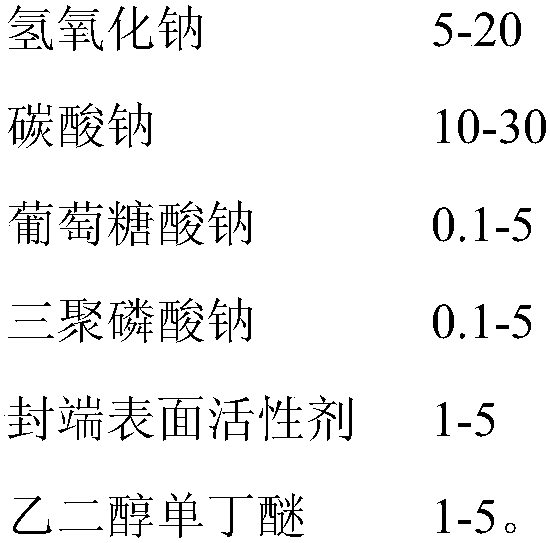

A stable powdery metal degreasing agent is successfully developed in the invention. A surfactant is chemically modified to generate a new terminated surfactant, and the new terminated surfactant is used to prepare the powdery metal degreasing agent in order to improve the stability of the surfactant in the powdery degreasing agent in a strong alkali system. The powdery degreasing agent comprises,by weight, 5-20 parts of sodium hydroxide, 10-30 parts of sodium carbonate, 0.1-5 parts of sodium gluconate, 0.1-5 parts of sodium tripolyphosphate, 1-5 parts of the terminated surfactant and 1-5 parts of ethylene glycol monobutyl ether.

Description

technical field [0001] The invention relates to the technical field of metal surface cleaning, in particular to a stable powdery metal degreasing agent. Background technique [0002] During the manufacture, transportation, storage and use of metal workpieces, due to the needs of machining and rust prevention, the surface is coated with grease. These oils are based on mineral oil and vegetable oil, and are added with various organic or inorganic additives. Therefore, in the surface treatment of metal materials, degreasing is an important process, and the degreasing degree of the metal surface will directly affect the subsequent processing quality of the workpiece. [0003] The oil composition on the surface of metal workpieces is relatively complex. One type is saponified oil based on fatty acid glyceride, which can be removed by saponification with alkali; the other type is mineral oil (non-saponified oil), which can be removed by emulsification. [0004] At present, most ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23G1/14

Inventor 何宗文侯伟何宗俊

Owner 合肥普庆新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com