IGBT layout capable of carrying out terminal transverse puncture tests

A technology of lateral withstand voltage and layout, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of insufficient withstand voltage, insufficient withstand voltage in the terminal area, and insufficient withstand voltage in the cell area, and achieve a good guiding role. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the specific drawings and embodiments.

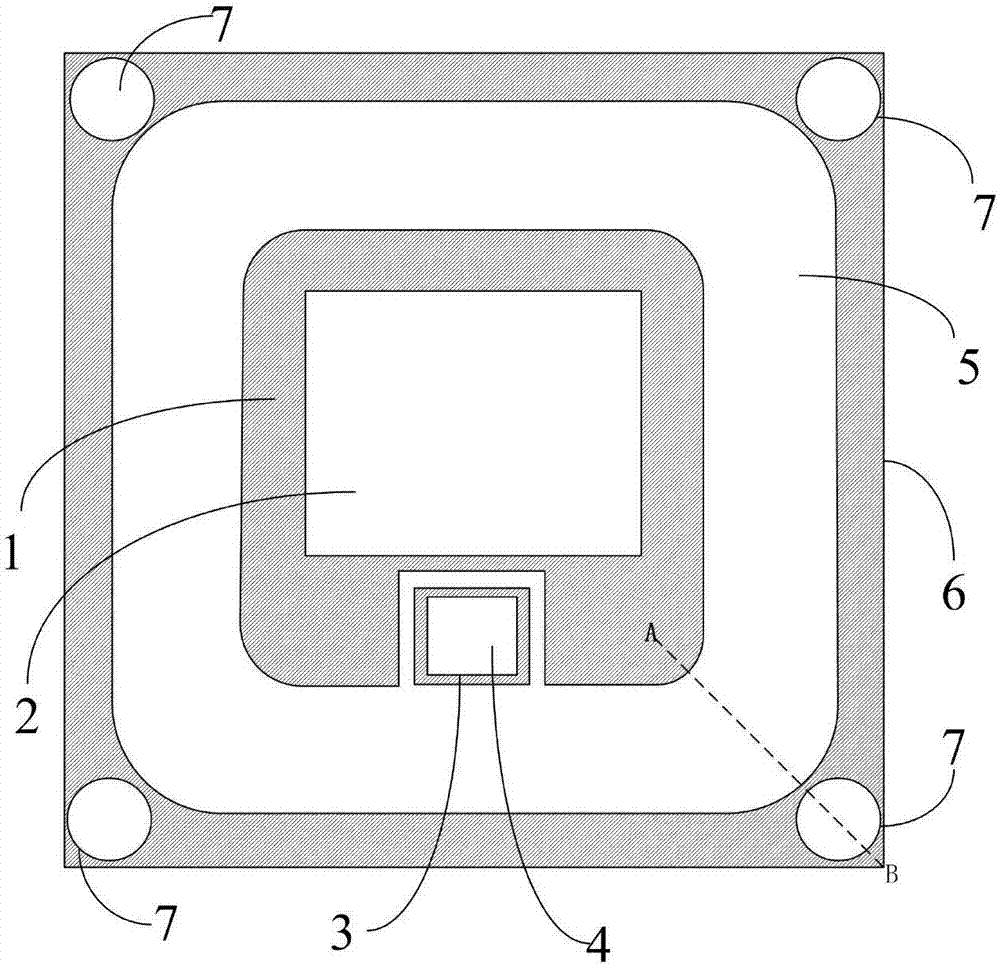

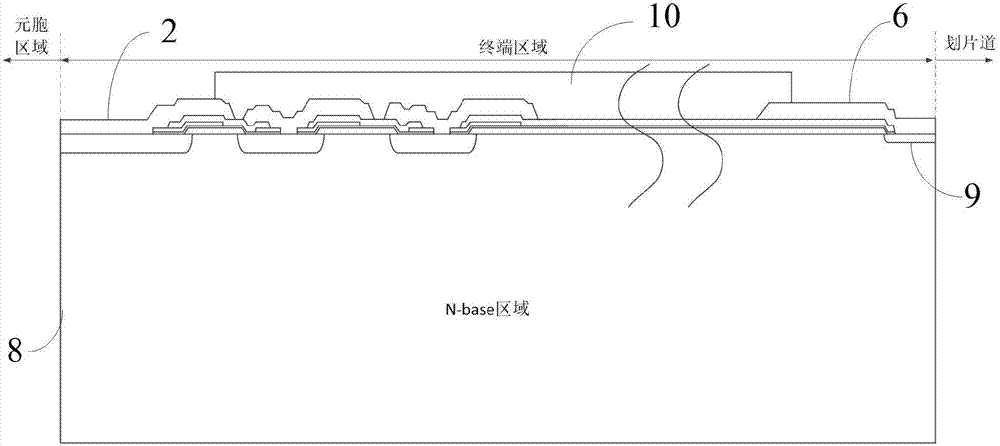

[0015] like figure 1 Shown: In order to effectively carry out the lateral withstand voltage test of the terminal and help to determine the condition of insufficient withstand voltage of the IGBT, the present invention includes a semiconductor substrate, a cell area is arranged in the central area of the semiconductor substrate, and a terminal located in the outer circle of the cell area is provided. Area 5, a source metal 1 and a source pressure pad 2 electrically connected to the source metal 1 are arranged above the cell area; it also includes an auxiliary test pressure pad 7 used to lead out the base area of the terminal area 5, so The auxiliary test pads 7 are located above the terminal area 5 .

[0016] Specifically, the cell region is used to form the functional region of the IGBT device, the terminal region 5 is used to protect the cell region and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com