Monitoring method for tungsten metal contamination of ion implanter

An ion implanter and metal technology, which is applied in the manufacture of discharge tubes, electrical components, semiconductor/solid-state devices, etc., can solve the problems of easily affected by the quality of controlled chips, poor test stability, long test time, etc., and achieve good test stability. , fast monitoring, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention are given below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in very simplified form and use imprecise ratios, which are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

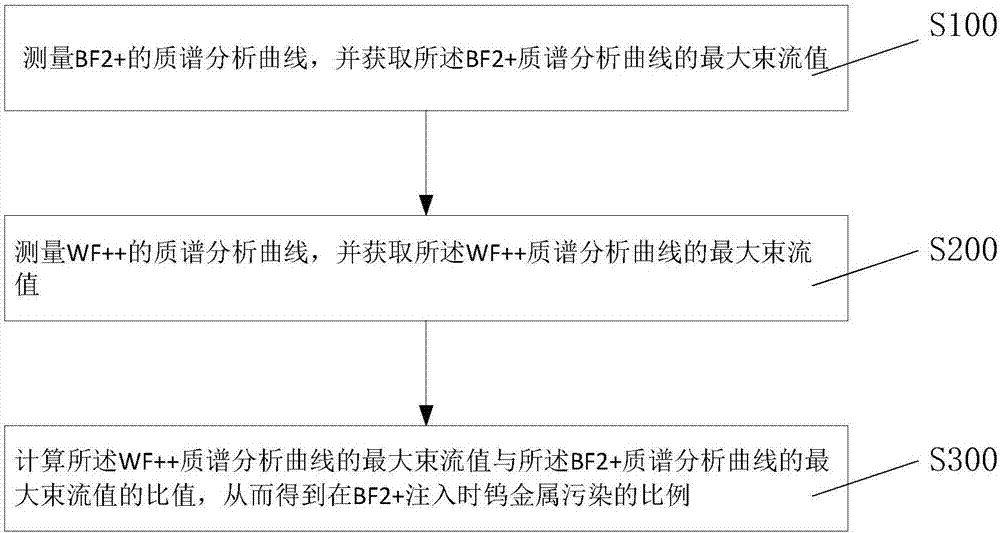

[0022] Please refer to figure 1 , figure 1 Shown is a flow chart of the method for monitoring tungsten metal contamination of an ion implanter in a preferred embodiment of the present invention. The present invention proposes a monitoring method for tungsten metal contamination of an ion implanter, comprising the following steps:

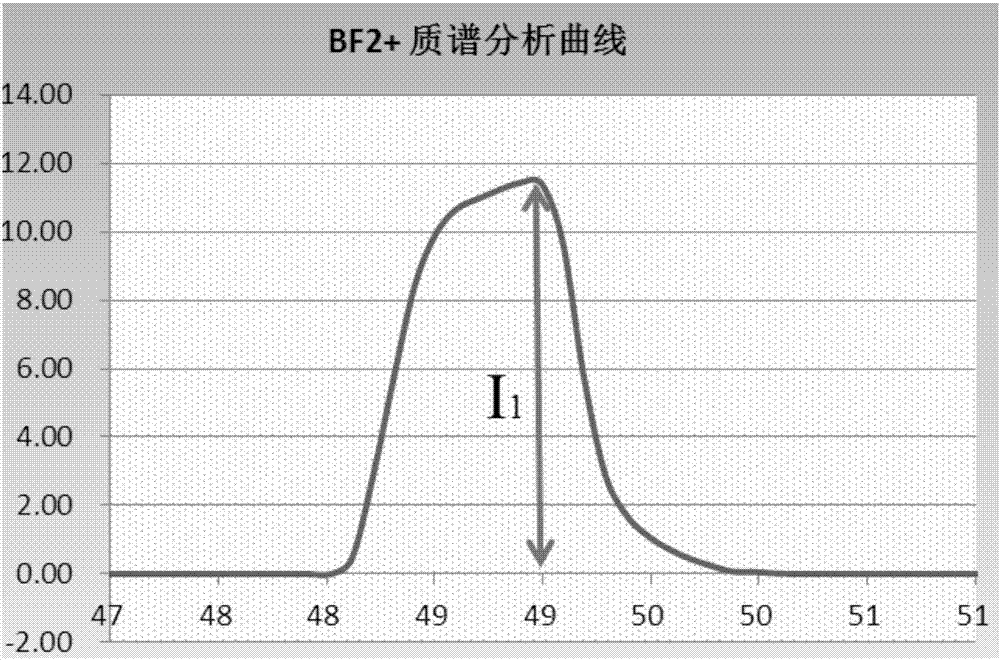

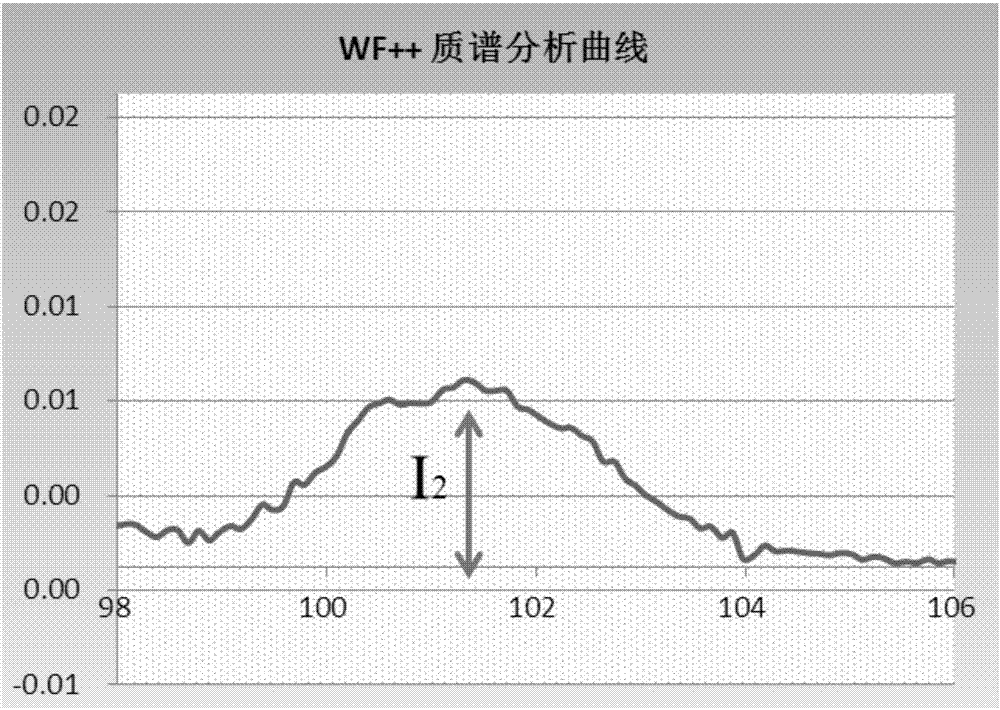

[0023] Step S100: measuring the mass spectrometry curve of BF2+, and obtaining the maximum beam current value of the BF2+ mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com