An equipment ice melting method, device and system based on the microwave technology

An ice-melting method and equipment technology, which can be applied to measurement devices, optical devices, general control systems, etc., and can solve the problems of lack of ice-melting means for de-icing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

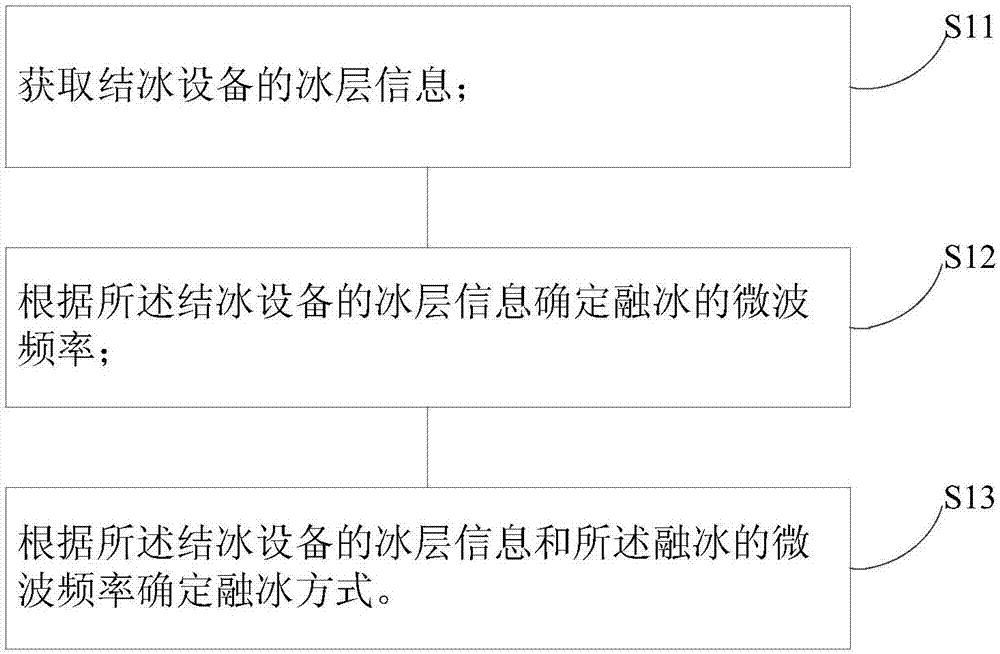

[0047] This embodiment provides a method for melting ice of equipment based on microwave technology. The flow chart of the method is as follows figure 1 shown. Including the following steps:

[0048] S11: Obtain ice layer information of the icing equipment. The ice layer information of the icing equipment can be obtained through actual measurement, and can also be obtained through image acquisition equipment. The ice layer image obtained by the image acquisition equipment can be analyzed to obtain the ice layer information of the icing equipment, such as ice layer shape, ice length and ice thickness etc.

[0049] S12: Determine a microwave frequency for melting ice according to the ice layer information of the icing device. The frequency of the ice-melting microwave for different ice layer information is preset according to the ice layer information of the icing equipment. Microwave frequency has the greatest impact on deicing efficiency, increasing microwave frequency can...

Embodiment 2

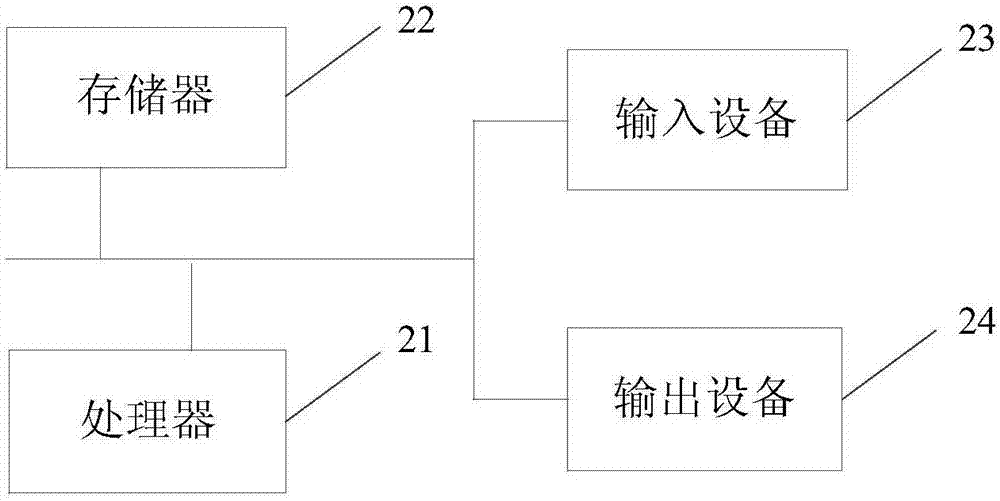

[0070] This embodiment provides an equipment ice-melting device based on microwave technology. The hardware structure diagram of the device is as follows figure 2 As shown, it includes at least one processor 21 and a memory 22 communicatively connected with the at least one processor, figure 2 A processor 21 is taken as an example. The apparatus may also include an input device 23 and an output device 24 .

[0071] The processor 21, the memory 22, the input device 23 and the output device 24 may be connected by a bus or in other ways, figure 2 Take connection via bus as an example.

[0072] The processor 21 may be a central processing unit (Central Processing Unit, CPU). Processor 21 can also be other general-purpose processors, digital signal processor (Digital Signal Processor, DSP), application specific integrated circuit (Application Specific Integrated Circuit, ASIC), field programmable gate array (Field-Programmable Gate Array, FPGA) or Other chips such as program...

Embodiment 3

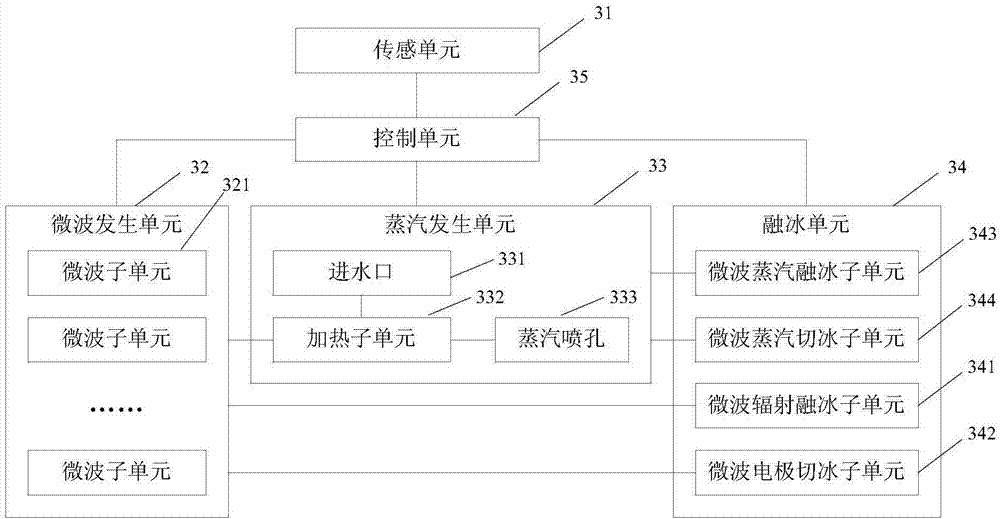

[0077] This embodiment provides an equipment ice melting system based on microwave technology, the system is as image 3 shown. It includes a sensing unit 31 , a microwave generating unit 32 , a steam generating unit 33 , an ice melting unit 34 and a control unit 35 .

[0078] The sensing unit 31 is configured to acquire ice layer information of the icing equipment. Specifically, the sensing unit may include an image acquisition device, and the ice layer image obtained by the image acquisition device is analyzed to obtain ice layer information of the icing device, such as ice layer shape, ice layer length, and ice layer thickness.

[0079] The microwave generating unit 32 includes a plurality of microwave subunits 321 for stably outputting high-power microwaves. Multiple microwave subunits 321 are designed through unit modularization, and high-power microwaves are synthesized by several independently working subunits. Each sub-unit controls the microwave power through an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com