Small and medium-sized large temperature difference dual-working condition dynamic fluid ice storage air conditioner

An ice-storage air-conditioning and large temperature difference technology, which is applied in air-conditioning systems, space heating and ventilation, heating methods, etc., can solve the problem that air-conditioning pipes cannot be directly used, it is difficult to achieve large temperature difference air-conditioning, and ice is easy to form large ice cubes, etc. problems, to achieve the effect of high-density transportation, high ice-making efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment and accompanying drawing, the present invention is described in detail:

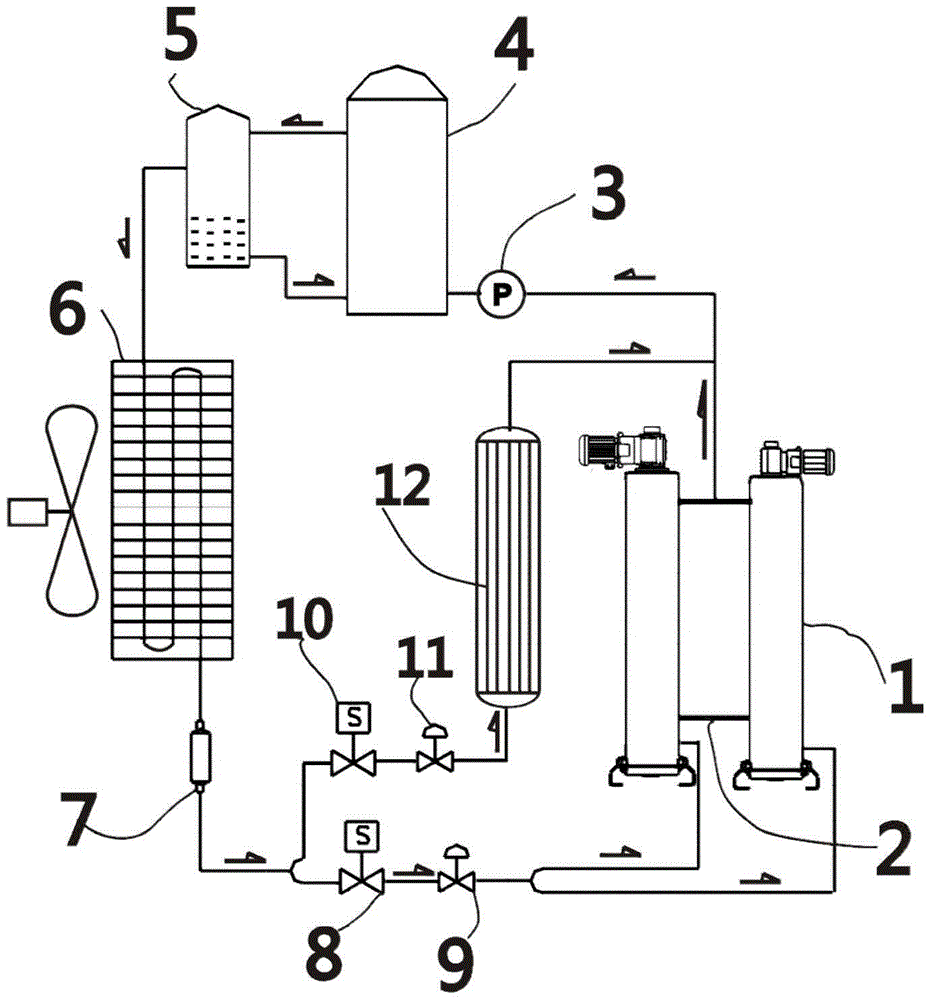

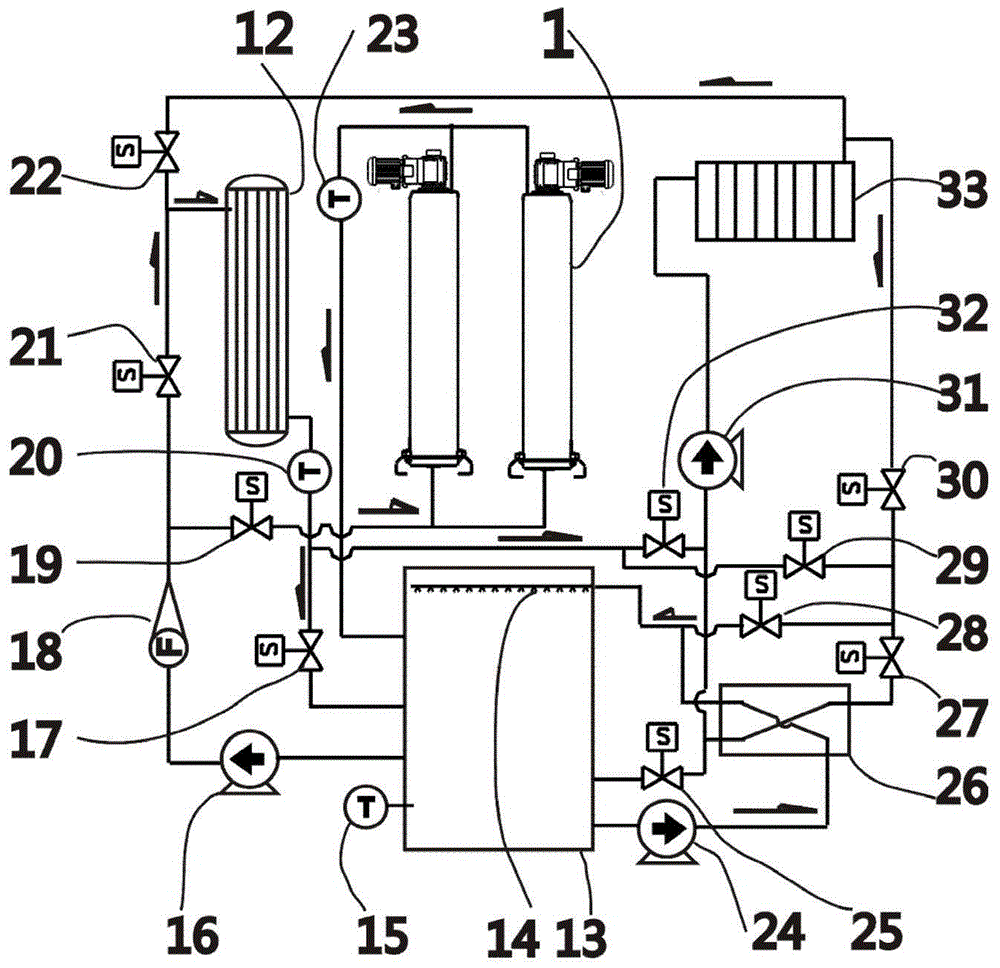

[0019] As shown in the accompanying drawings, the small and medium-sized large temperature difference dual-working condition dynamic fluid ice ice storage air conditioner of the present invention includes a refrigeration cycle device and an air conditioning cycle device, and the refrigeration cycle device includes a water-cooled evaporator 12 and at least one ice crystal device 1. A plurality of ice crystals 1 are connected through the ice crystal refrigerant connection channel 2, and the air conditioning cycle device includes an ice storage tank 13 equipped with a third temperature sensor 15, on the upper part of the ice storage tank A spraying device is installed, and the first water outlet at the bottom of the ice storage tank 13 is connected with the water inlet of the ice-making circulation pump 16, and the water outlet of the ice-making circulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com