Method for acquiring electro-hydraulic pulse shock wave intensity under high static pressure

A technology of hydraulic pulse and shock wave intensity, which is applied to electrical devices, electric vehicles, and measuring electrical variables, etc., and can solve the technical difficulties of hydraulic pulse shock wave intensity measurement and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

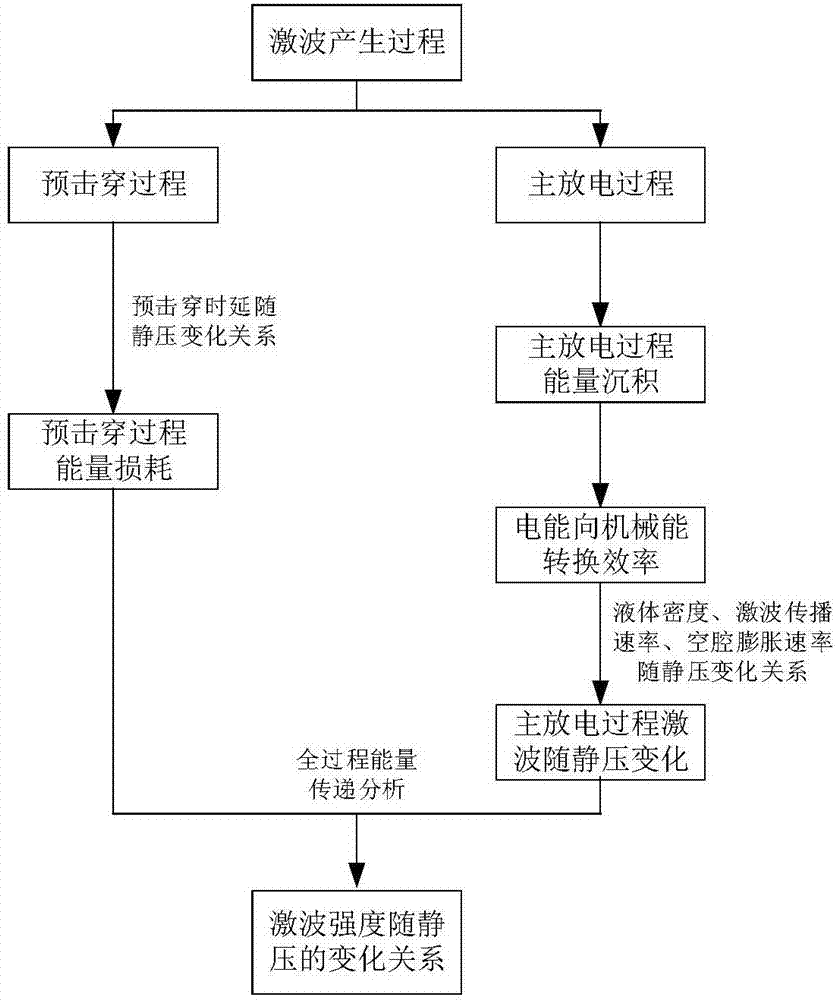

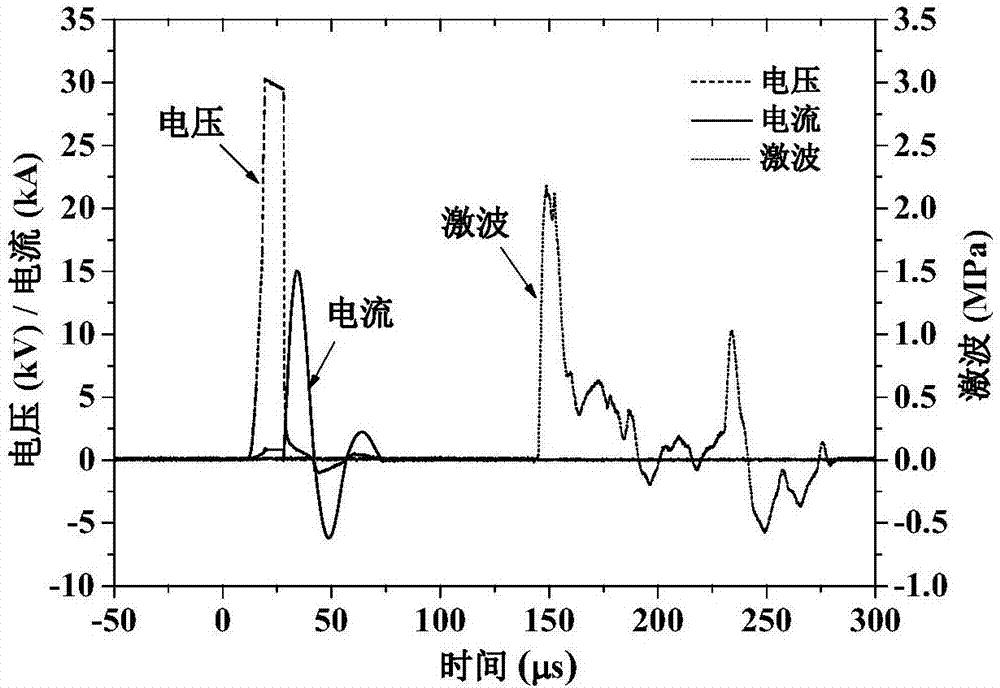

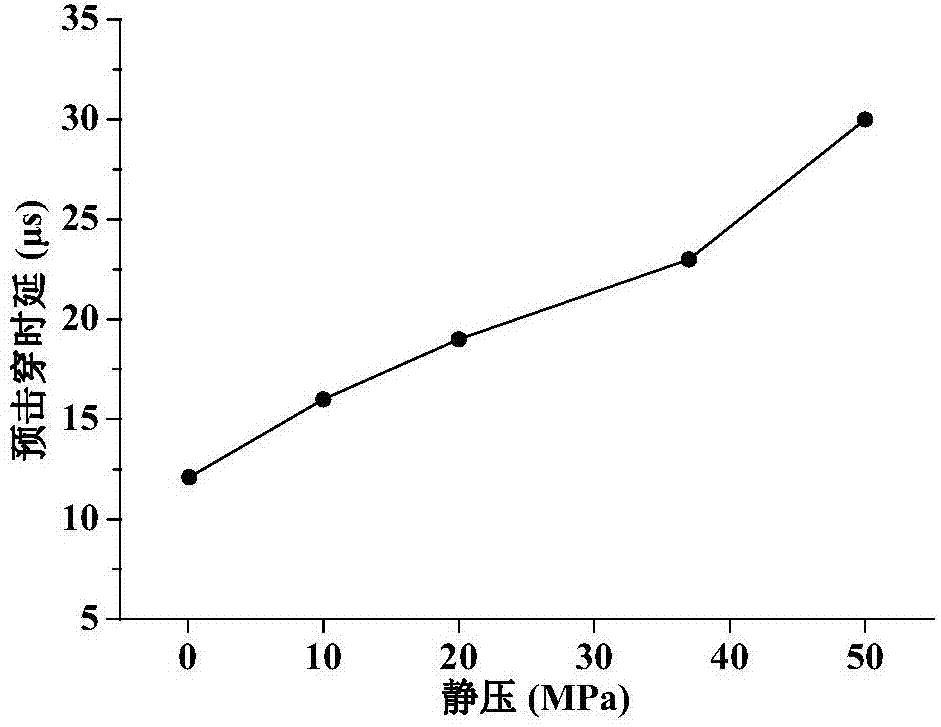

[0023] The present invention proposes a method for obtaining the shock wave intensity of the hydraulic pulse under high static pressure, which mainly divides the shock wave generation process into two stages: the pre-breakdown process and the main discharge process, and uses the pre-breakdown time delay to vary with the static pressure The energy loss in the pre-breakdown process is calculated according to the change relationship, and the influence of static pressure on liquid density, shock wave propagation velocity and cavity expansion rate is considered, and the conversion efficiency of electrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com