Nanometer positioner for transmission electron microscope sample rods

A transmission electron microscope sample and locator technology, which is applied to the use of wave/particle radiation for material analysis, instruments, circuits, etc., can solve the problems of easy deformation of flexible silk claws, falling of probe clamping devices, and complicated relationships, etc., to achieve Simple and clear connection relationship, improved stability, and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

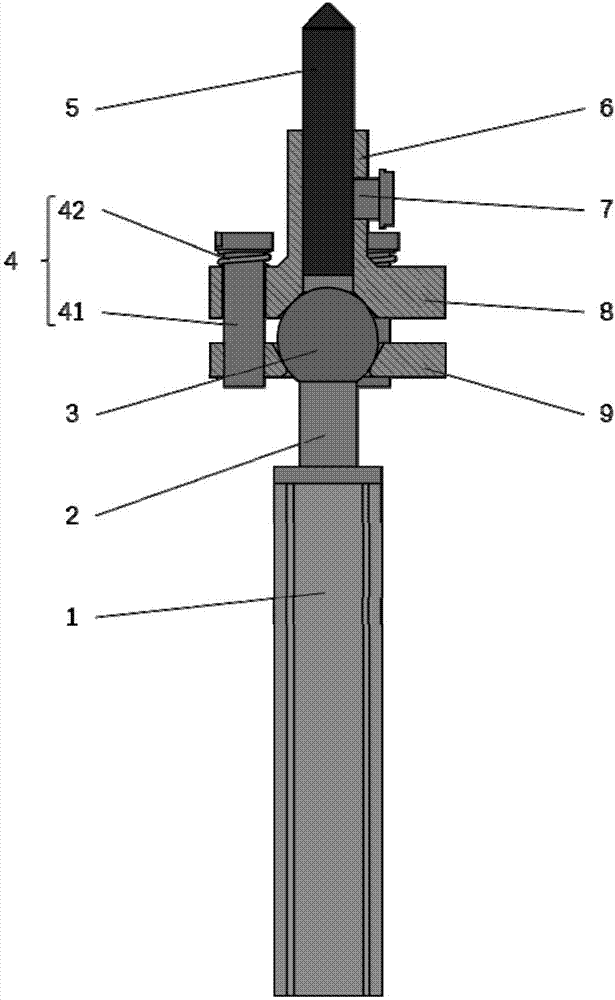

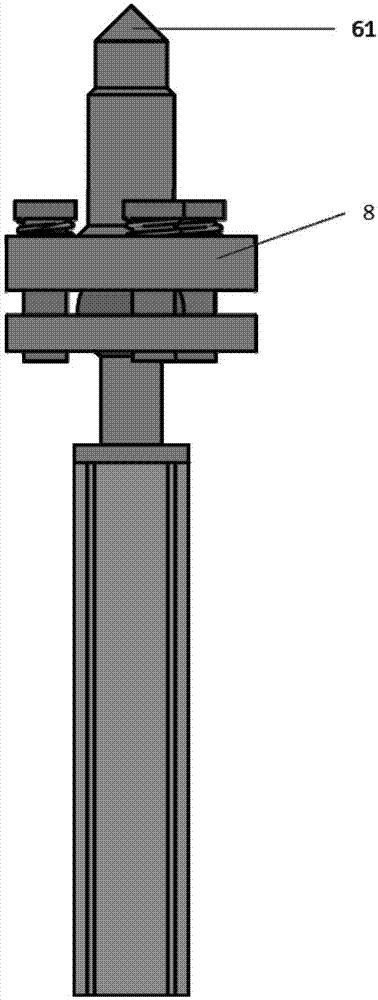

[0025] Such as figure 2 As shown, the nanopositioner used for the sample rod of the transmission electron microscope includes a sample rod head and a sample rod body, the sample rod head is used to load the sample, and the sample rod body is a piezoelectric ceramic tube 1;

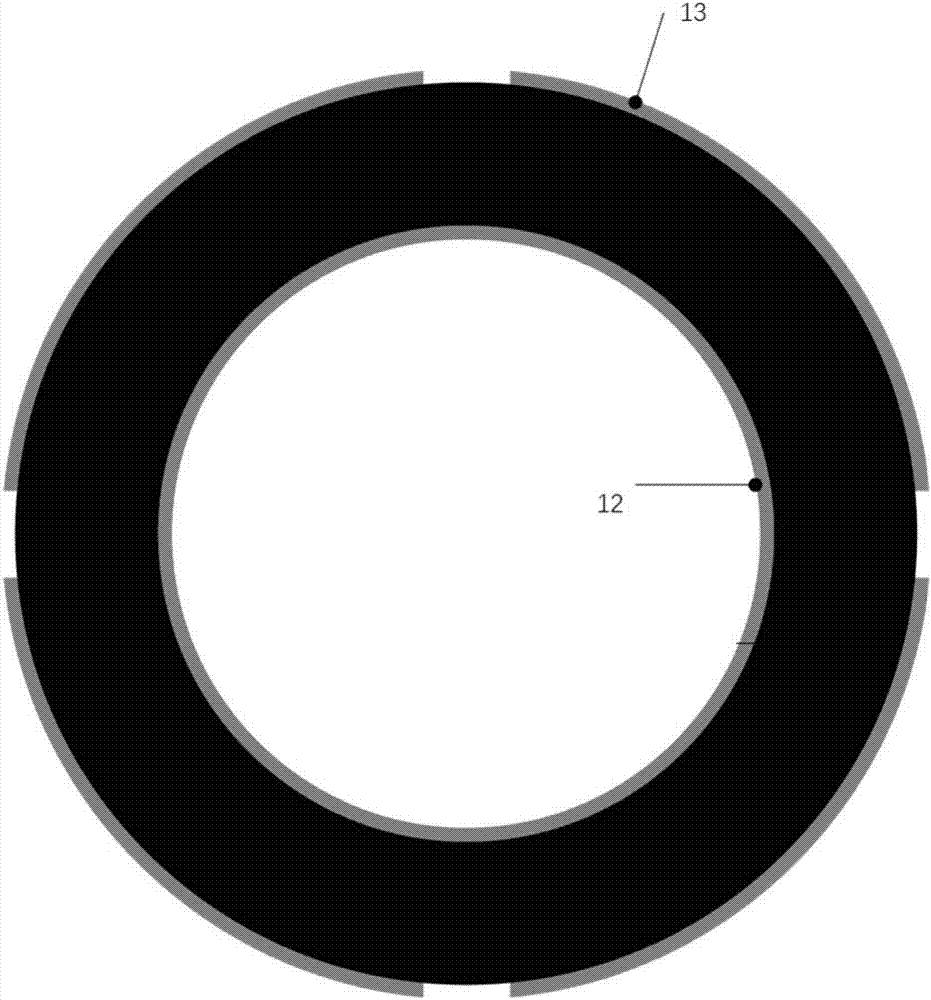

[0026] The circumferential wall of the piezoelectric ceramic tube 1 is evenly provided with a plurality of mutually independent conductive regions 13, and the head end of the piezoelectric ceramic tube 1 has a fixed joint ball 3, and the joint ball 3 is fixed on the head end of the ball seat 2, and the ball seat The end of 2 is fixed on the head end of piezoelectric ceramic tube 1. The piezoelectric ceramic tube 1 is a tubular member made of piezoelectric ceramic material, its inner wall surface 12 is completely covered by a conductive coating, and its outer wall surface is coated with a plurality of mutually insulated conductive coatings, and the mutually insulated conductive coatings form Conductive re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com