A method of assembling a coupling

An assembly method and coupling technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of affecting work efficiency, long installation time, and many production processes, so as to enhance the overall stability and improve the The effect of using safety and improving the efficiency of changeover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

[0020] Non-limiting and non-exclusive embodiments will be described with reference to the following drawings, wherein like reference numerals refer to like parts unless specifically stated otherwise.

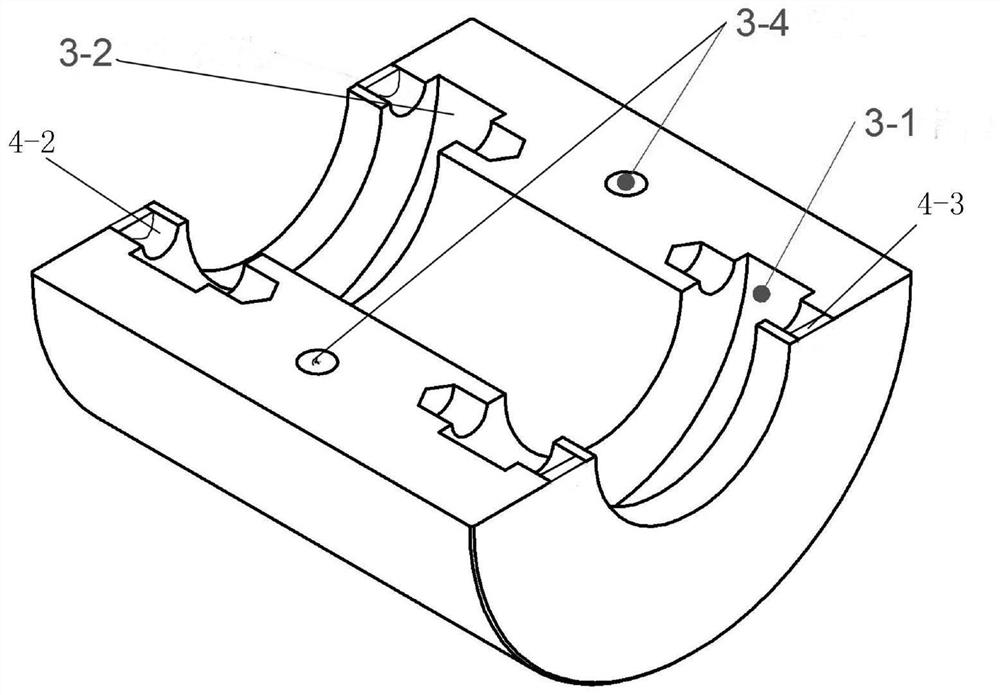

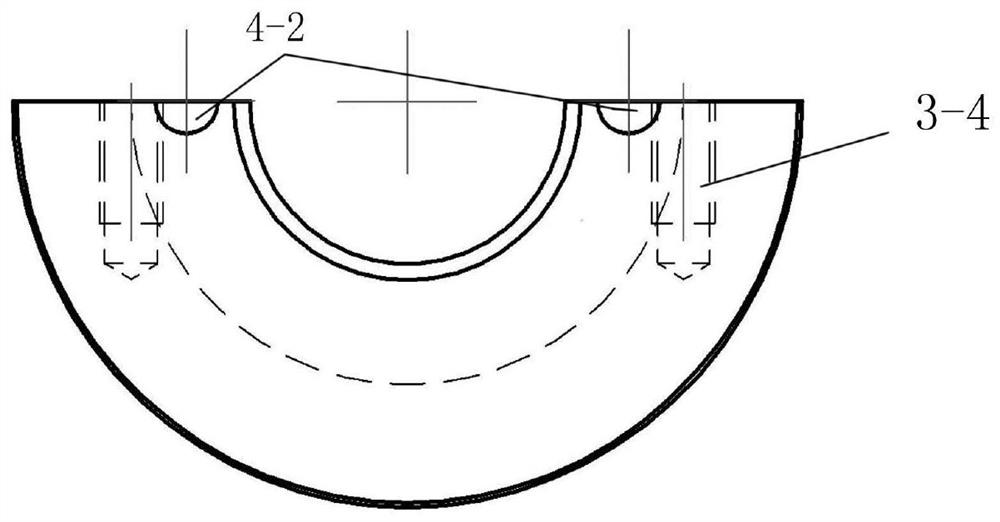

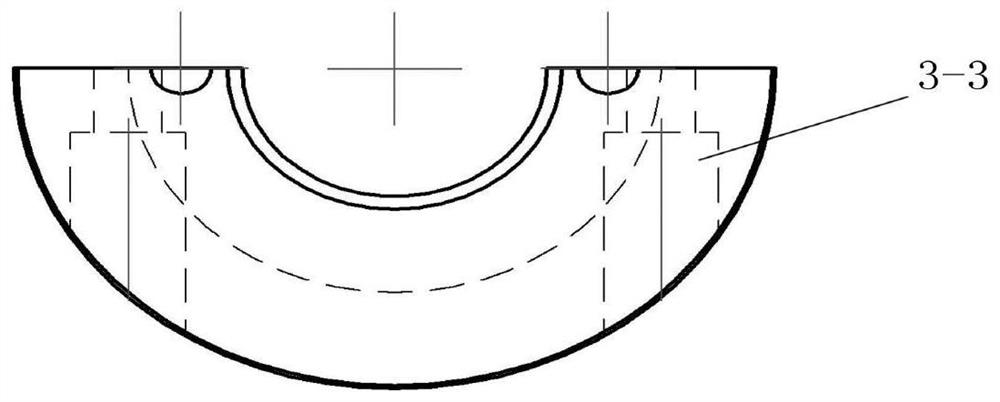

[0021] Such as Figure 1-6 As shown in a coupling, the middle part of the coupling 3 is provided with an axial inner hole, and the inner hole is a central through hole; the coupling 3 is evenly divided into the upper half coupling by a plane passing through its central axis, Coupling half. The upper half of the coupling is provided with a stepped hole 3-3, which is convenient for locking the countersunk head of the bolt 5, and the position of the lower half of the coupling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com