Self-cleaning type sound barrier

A sound barrier and self-cleaning technology, which is applied in construction, noise absorption devices, etc., can solve the problems of poor pollutant removal effect, poor sound insulation effect of sound barrier, and difficult assembly and installation, so as to achieve good sound absorption effect, Simple structure, not easy to attach

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

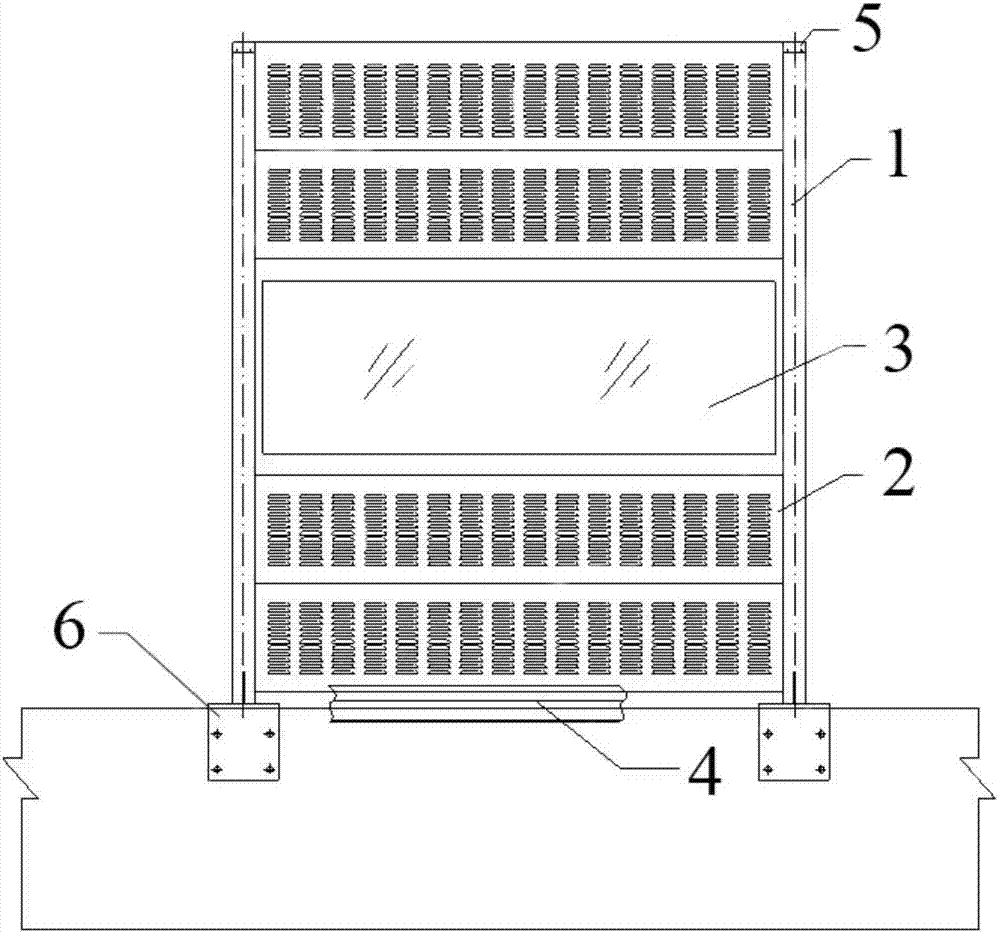

[0055] A self-cleaning sound barrier disclosed by the present invention comprises two parallel uprights 1, wherein a sound screen plate is arranged between the two uprights, and the side of the upright 1 facing the sound screen plate is provided with a 1. A card slot opened in the length direction, and the side of the sound screen plate is locked in the card slot.

[0056] The surface of the column and the sound screen plate is coated with a nano-titanium dioxide photocatalyst coating.

[0057] The surface of the base material 9 of the self-cleaning sound barrier includes: the outer surface of the column 1, the front and rear panels 11 of the sound absorption screen 2, the surface of the sound insulation screen 3 and the outer surface of the window frame and the lower cover plate 4 are coated with nano-titanium dioxide Photocatalyst coating.

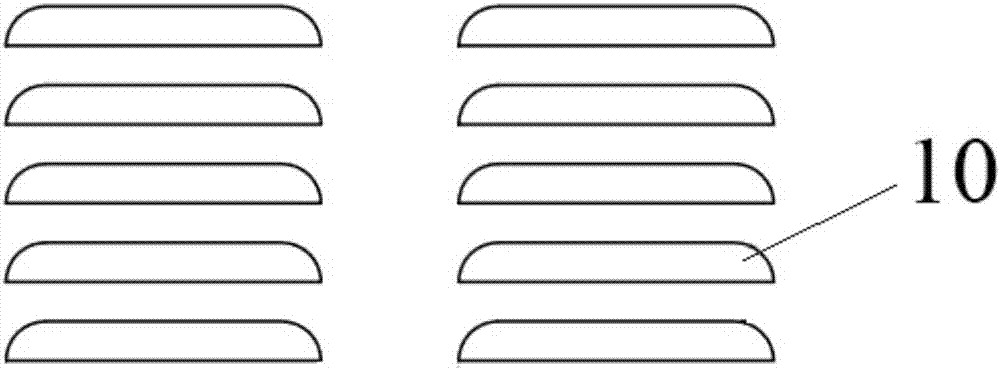

[0058] The nano-titanium dioxide photocatalyst coating includes a silicon-containing intermediate layer 8 and nano-TiO 2 Self-cleanin...

Embodiment 2

[0075] The difference between the self-cleaning sound barrier disclosed in this embodiment and the previous embodiment is that the sound-absorbing screen 2 is installed between the two columns 1, and the sound-insulating screen 3 and the window frame are no longer installed, so that not only the self-cleaning sound barrier can be added The contact area with the sound wave increases the attenuation rate of the sound wave, shortens the process of absorbing the sound wave, and enhances the sound insulation effect of the sound barrier. Moreover, the overall structure is integrated, the structure is simple, and the assembly is convenient. The construction cost maximizes the use of social resources, which is in line with the scientific development concept and the central spirit of building a conservation-oriented society; an upper cover is installed above the self-cleaning sound barrier to protect the lower sound-absorbing screen 2 from the upper The impact of the environment can avo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com