Nanostructure-based high-energy-absorption and high-manganese type TWIP steel and preparation method thereof

A nanostructure, high manganese technology is applied in the field of high energy absorption high manganese TWIP steel and its preparation, and can solve the problems of reducing plasticity and reducing the energy absorption capacity of TWIP steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation steps of Example 1: smelting components (mass fraction, %) are C: 0.703%, Mn: 19.79%, Al: 2.01%, V: 0.516%, Nb: 0.041%, and the balance of Fe.

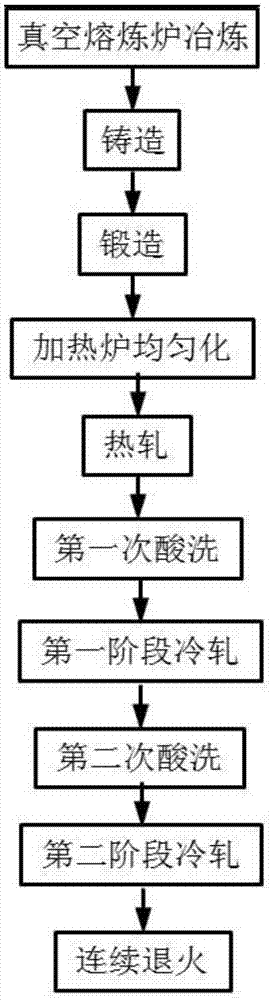

[0036] according to figure 1 The preparation process flow of the casting billet is forged into a billet with a thickness of 40mm after being held at 1150°C for 1.5h, homogenized in a heating furnace at 1200°C for 1.8h; rolling is started at 1120°C, and rolled to 4± through 5 passes 0.05mm, final rolling temperature 850°C, pickling and two-stage cold rolling after air cooling to room temperature, final thickness 1.2±0.02mm; keep at 620°C for 3.5min in continuous annealing furnace, then cool at 20°C / s to room temperature.

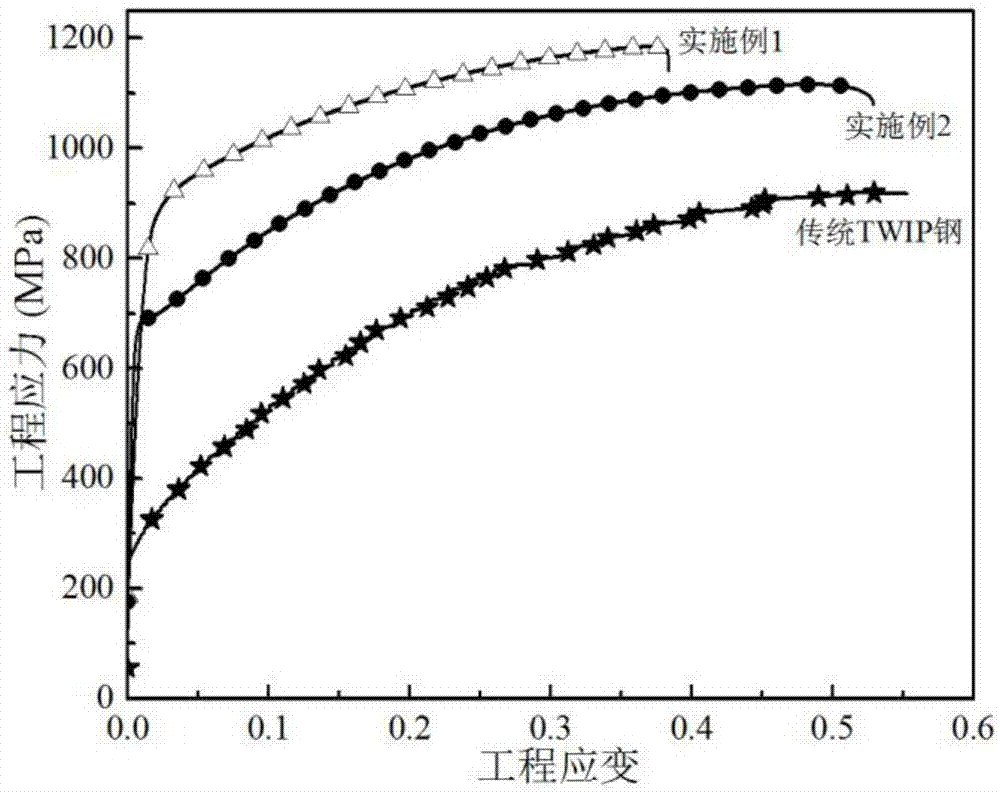

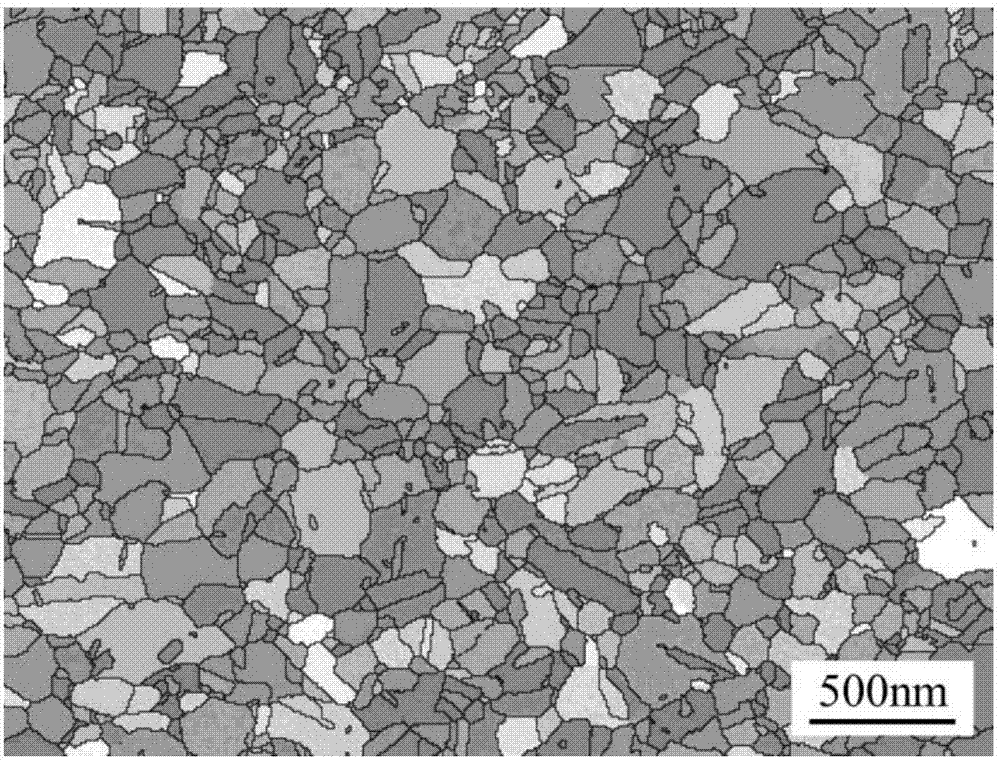

[0037] The structure of the TWIP steel obtained in Example 1 is a single austenite structure, the average grain size is about 220nm, and there are about 20-40nm precipitates evenly distributed thereon, the yield strength is 816MPa, and the tensile strength is 1183MPa. The elongation rate is 38.25...

Embodiment 2

[0038] Preparation steps of Example 2: smelting components (mass fraction, %) are C: 0.697%, Mn: 19.85%, Al: 2.21%, V: 0.521%, Ti: 0.032%, and the balance of Fe.

[0039] according to figure 1 The preparation process flow of the casting billet is forged into a billet with a thickness of 40mm after being held at 1150°C for 1.5h, homogenized in a heating furnace at 1200°C for 1.8h; rolling is started at 1120°C, and rolled to 4± through 5 passes 0.05mm, final rolling temperature 850°C, pickling and two-stage cold rolling after air cooling to room temperature, final thickness 1.2±0.02mm; keep at 680°C for 3.5min in the continuous annealing furnace, then cool at a cooling rate of 20°C / s to room temperature.

[0040] The structure of the TWIP steel obtained in Example 2 is a single austenite structure, the average grain size is about 305nm, and there are about 25-40nm precipitates evenly distributed on it, the yield strength is 667MPa, and the tensile strength is 1116MPa. The elonga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com