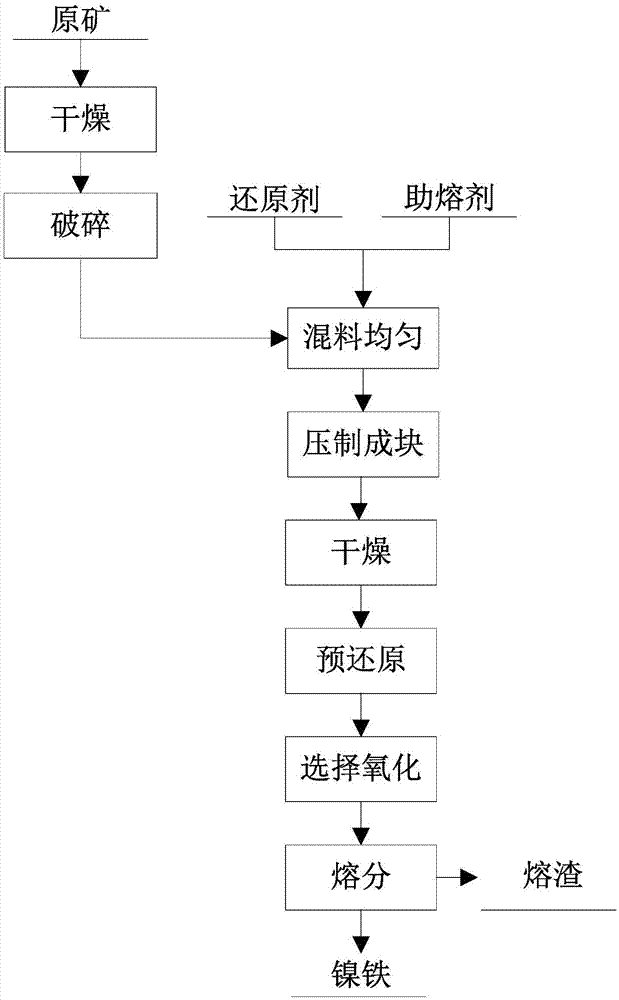

Method for preparing ferronickel by enriching nickel in laterite-nickel ore

A technology of laterite nickel ore and ferronickel is applied in the field of metallurgy, which can solve the problems of increasing the difficulty of stainless steel smelting, and achieve the effect of good nickel recovery, avoiding corrosion to equipment and high nickel content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

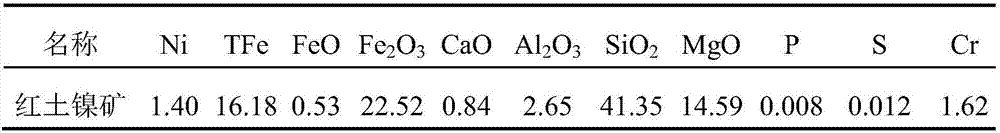

[0024] Dry the laterite nickel ore and crush it to -5mm. The reducing agent is added to the coal powder according to the excess of 40% of the internal carbon. 0.5%. Various raw materials are fully mixed and pressed into blocks, and fully pre-reduced in a tunnel kiln at a temperature of 1100-1200 ° C. The pre-reduced product is oxidized in the furnace with the atmosphere, the secondary oxidation temperature is 1000-1150 ° C, and the oxidation time is 120 Minutes, the oxidized product is melted in a submerged arc furnace at 1450-1500°C for 30 minutes to separate the slag and gold to obtain ferronickel. Through experimental analysis, the contents of nickel and iron in the ferronickel product are 12.97% and 79.97% respectively, and the recovery rates of nickel and iron are 92.64% and 49.43% respectively.

Embodiment 2

[0026] Dry the laterite nickel ore and crush it to -5mm. The reducing agent is added to coal powder according to the excess internal carbon content of 20%. The amount of flux fluorite added is 8% of the laterite nickel ore. 1.5%. Various raw materials are fully mixed and pressed into blocks, and fully pre-reduced at a temperature of 1100-1200°C in a rotary kiln. The pre-reduced product is selectively oxidized at 900-1100°C under an atmospheric atmosphere, and the oxidation time is 30 minutes. The oxidized product is melted in a submerged arc furnace at 1400-1450°C for 30 minutes to separate slag and gold to obtain ferronickel. Through experimental analysis, the contents of nickel and iron in the ferronickel product are 13.56% and 81.46% respectively, and the recovery rates of nickel and iron are 91.86% and 48.88% respectively.

Embodiment 3

[0028]Dry the laterite nickel ore and crush it to -5mm. The reducing agent is added to coal powder according to the excess internal carbon content of 20%. The amount of fluxing agent fluorite added is 15% of the laterite nickel ore. 1.0%. Various raw materials are fully mixed and pressed into blocks, and fully pre-reduced at a temperature of 1100-1150 °C in a rotary kiln. The pre-reduced product is selectively oxidized at 800-1150 °C under an atmospheric atmosphere, and the oxidation time is 30 minutes. The oxidized product is melted in a submerged arc furnace at 1350-1400°C for 30 minutes to separate slag and gold to obtain ferronickel. Through experimental analysis, the contents of nickel and iron in the ferronickel product are 14.94% and 81.2% respectively, and the recovery rates of nickel and iron are 98.6% and 46.37% respectively.

[0029] In embodiment 1,2,3, the rate of recovery of nickel after the pre-reduction product is oxidized is all higher than 90%, and the rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com