A kind of preparation method and application of catalyst

A catalyst and reaction technology, which is applied in the preparation of organic compounds, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unfriendly environment and achieve good catalytic life and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of Fe 3 o 4 : Weigh 4mmol anhydrous ferric chloride (FeCl 3) was dissolved in 40 mL of diethylene glycol (DEG), so that the concentration of anhydrous ferric chloride in diethylene glycol was 0.1 mmol / mL. Then add 1.6mmol of sodium citrate and 12mmol of anhydrous sodium acetate, stir and dissolve in a water bath at 80°C. The solution was then transferred to an autoclave and reacted in an oven at 240 °C for 6 h. Then, it was washed with ethanol using a magnet to obtain a black powder, which was dried in a vacuum oven at 60°C. get Fe 3 o 4 .

[0035] (2) Preparation of HAP@Fe 3 o 4 : Weigh 1 g of Fe prepared in step 1 3 o 4 Dispersed into 35mL aspartic acid solution to obtain a concentration of 1g / 35mL Fe 3 o 4 dispersion of aspartic acid. Then, after stirring in a water bath at 80° C. for 2 h, it was washed with water. The resulting powder was then dispersed into 100 mL ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) solution, while adding...

Embodiment 2

[0040] Same as Example 1, only change the 1,2-propanediol solution in step (5) of Example 1 to 0.4, 0.6 mol / L respectively. The results obtained are shown in Table 1. The results showed that with the increase of 1,2-propanediol concentration, the conversion rate of 1,2-propanediol increased and the selectivity of lactic acid also increased slightly.

[0041] The impact of different 1,2-propanediol concentrations on the conversion rate of the final raw material and the selectivity of the reaction product in table 1

[0042] 1,2-propanediol concentration (mol / L) 1,2-propanediol conversion rate (%) Lactic acid selectivity (%) 0.2 88 62.1 0.4 91 73.5 0.6 95 78.5

Embodiment 3

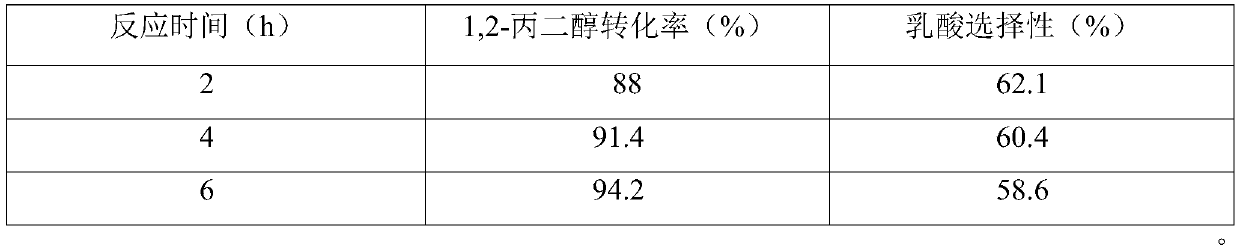

[0044] Same as in Example 1, only changing the reaction temperature in step (5) of Example 1 to 60 and 80°C respectively, and then performing catalytic 1,2-propanediol reaction, the results obtained are shown in Table 2. The results showed that the conversion of 1,2-propanediol increased and the selectivity of lactic acid decreased with the increase of reaction temperature.

[0045] The influence of table 2 different reaction temperatures on the conversion rate of final raw material and the selectivity of reaction product

[0046] Reaction temperature (°C) 1,2-propanediol conversion rate (%) Lactic acid selectivity (%) 40 88 62.1 60 90 60 80 96 53.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com