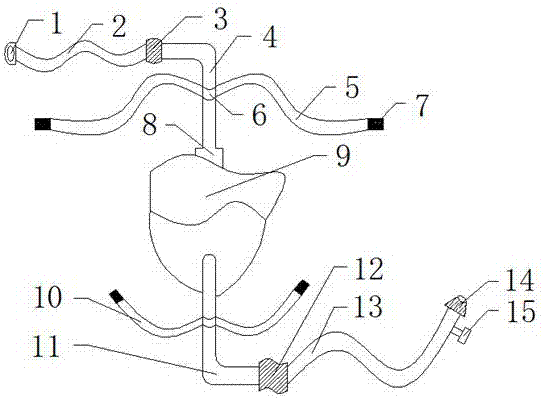

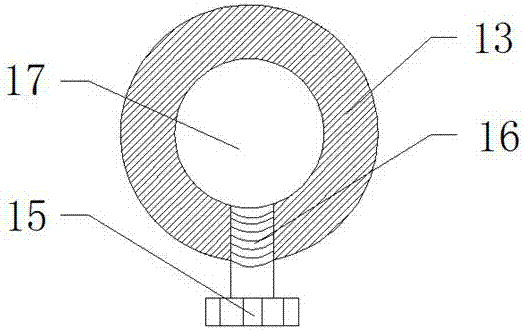

Portable urinary catheterization device

A portable, urine device technology, used in catheters, medical science, drainage devices, etc., can solve the problems of air pollution, unfavorable patient recovery, increase the burden of pouring urine, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

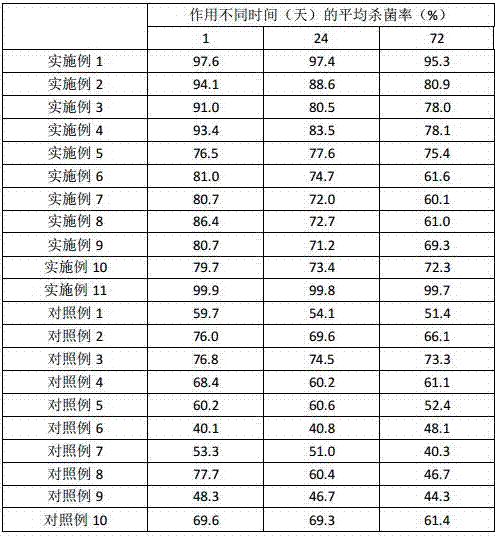

Embodiment 1

[0021] Include the following steps:

[0022] Step 1. Dissolve sodium alginate in water to make a solution with a mass concentration of 5 g / L, add 25% Fe-MOF nanomaterials, 5% glycerin, 10% Tween 80, and 5% Nitrate Parkin ethyl ester sodium, homogenized after stirring for 1h, adjusted to 4, then vacuum degassed for 0.5h;

[0023] Step 2. Pour the sodium alginate nano-Fe-MOF antibacterial coating solution prepared above into the leveling mold and dry it at 30°C for 24 hours, then pour it into a calcium chloride solution with a mass fraction of 5% for curing;

[0024] Step 3, dissolving polyvinyl alcohol in water to make a solution with a mass concentration of 30g / L, adding a mass fraction of 4% glycerin, 10% Tween 80 and 10% nano-TiO 2 , after stirring for 5 hours in a water bath at 80°C, homogenize;

[0025] Step 4, dissolving chitosan in 5% acetic acid by volume fraction is to make a solution that mass concentration is 10g / L, adding mass fraction is 12% glycerol, 12% Tween 8...

Embodiment 2

[0031] The difference from Example 1 is that in step 5, the polyvinyl alcohol and chitosan solution are mixed uniformly at 3:1, and the polyvinyl alcohol-chitosan nano-coating solution is obtained after vacuum degassing for 0.5h, and then after curing The Fe-MOF antibacterial coating solution was poured into the mold at a ratio of 1:3, dried at 30°C and then peeled off to obtain a polymer coating with antibacterial function. The rest of the preparation was the same as in Example 1.

Embodiment 3

[0033]The difference from Example 1 is that in step 5, the polyvinyl alcohol and the chitosan solution are mixed uniformly at 2:1, and the polyvinyl alcohol-chitosan nano-coating solution is obtained after vacuum degassing for 0.5h, and then after curing The Fe-MOF antibacterial coating solution was poured into the mold at a ratio of 1:3, dried at 30°C and then peeled off to obtain a polymer coating with antibacterial function. The rest of the preparation was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com