Aqueous zinc ion battery based on pyrene-4, 5, 9, 10-tetrone positive electrode and zinc negative electrode

A zinc ion battery, zinc ion technology, applied in battery electrodes, secondary batteries, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

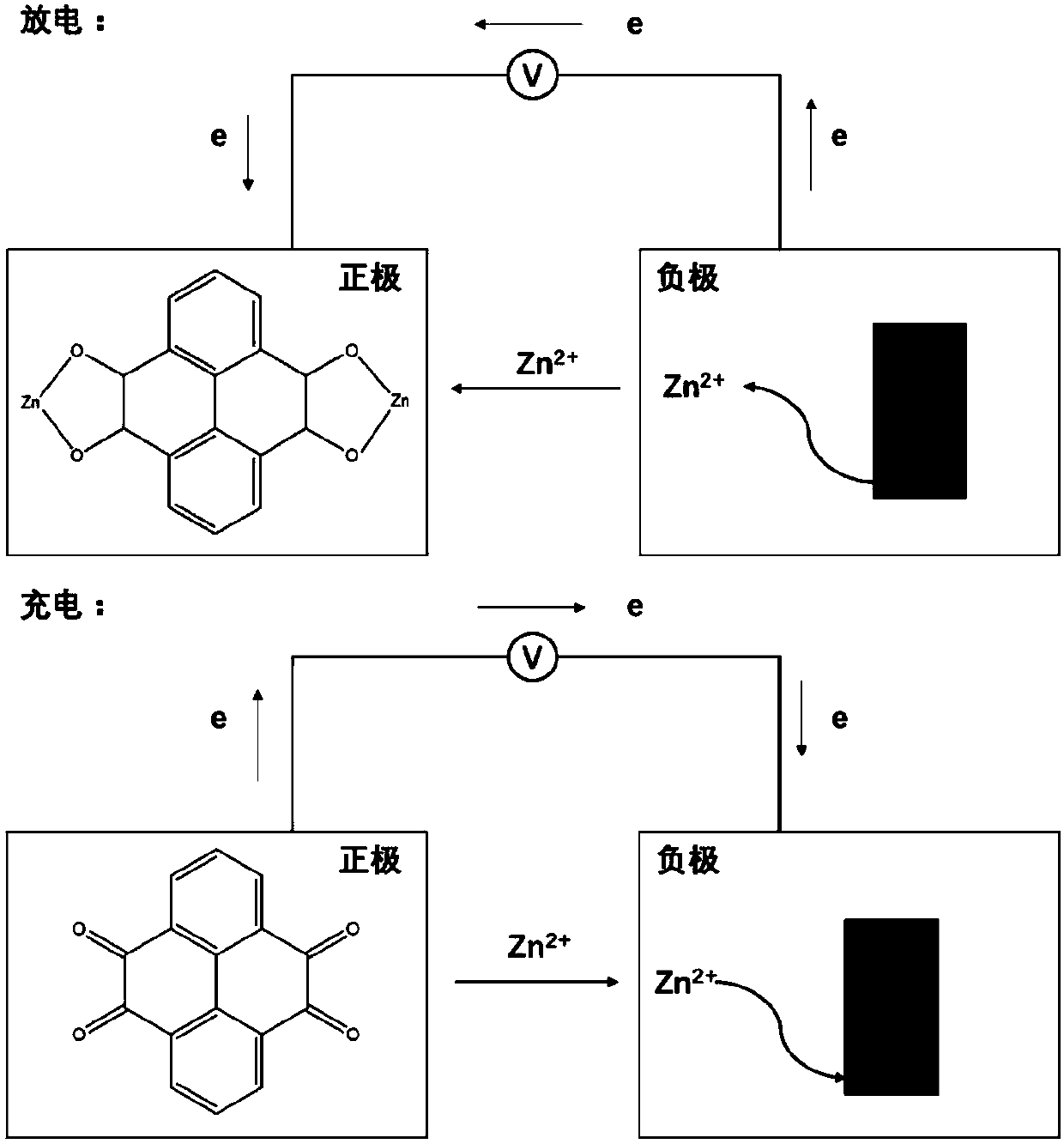

AI Technical Summary

Problems solved by technology

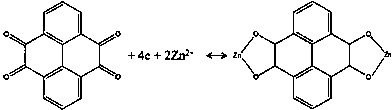

Method used

Image

Examples

Embodiment 1

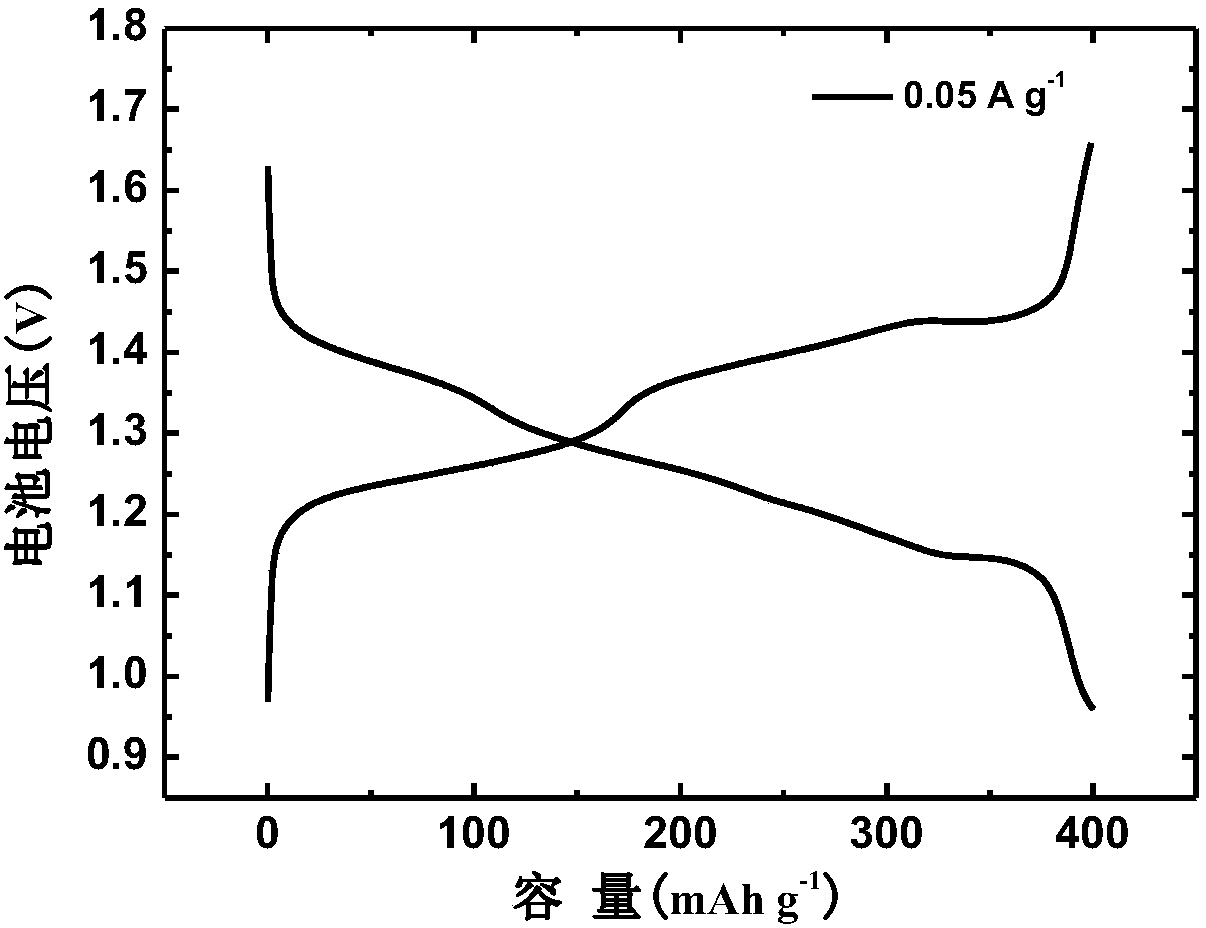

[0023] Example 1: The positive electrode uses carbon nanotubes as the conductive agent. The preparation of the positive electrode film is as follows: mix according to the ratio of active material (pyrene-4,5,9,10-tetraketone): conductive agent (carbon nanotubes): binder (polytetrafluoroethylene) = 60:30:10 , roll the mixed slurry on a roller press to form a thin film with uniform thickness, cut it into a size of 1cm*1cm after drying, and the loading capacity of pyrene-4,5,9,10-tetraketone is 5 mg cm -2 , and then uniformly press the positive electrode film on the titanium mesh, and lead out with nickel wire to form the positive electrode. The negative electrode is made of zinc foil, cut into a size of 1 cm*1 cm, and drawn out with nickel wire to form the negative electrode. Electrolyte is 1 M Zn 2 SO 4 solution, assembled into an aqueous zinc-ion battery. The assembled aqueous Zn-ion battery was charged and discharged on the electrochemical workstation (PARSTAT). The char...

Embodiment 2

[0024] Embodiment 2: Active carbon is used as the conductive agent in the positive electrode. The preparation of the positive electrode film is as follows: mix according to the ratio of active material (pyrene-4,5,9,10-tetraketone): conductive agent (activated carbon): binder (polytetrafluoroethylene) = 60:30:10, The mixed slurry was rolled into a thin film with uniform thickness on a roller press, dried and cut into a size of 1 cm*1 cm, and the loading capacity of pyrene-4,5,9,10-tetraketone was 5 mg cm -2, and then uniformly press the positive electrode film on the titanium mesh, and lead out with nickel wire to form the positive electrode. The negative electrode is made of zinc foil, cut into a size of 1 cm*1 cm, and drawn out with nickel wire to form the negative electrode. Electrolyte is 1 M Zn 2 SO 4 solution, assembled into an aqueous zinc-ion battery. The assembled aqueous Zn-ion battery was charged and discharged on the electrochemical workstation (PARSTAT). The ...

Embodiment 3

[0025] Example 3: Ordered mesoporous carbon (CMK-3) was used as the conductive agent in the positive electrode. The preparation of the positive electrode film is as follows: mix according to the ratio of active material (pyrene-4,5,9,10-tetraketone): conductive agent (CMK-3): binder (polytetrafluoroethylene) = 60:30:10 , roll the mixed slurry on a roller press to form a thin film with uniform thickness, cut it into a size of 1cm*1cm after drying, and the loading capacity of pyrene-4,5,9,10-tetraketone is 5 mg cm -2 , and then uniformly press the positive electrode film on the titanium mesh, and lead out with nickel wire to form the positive electrode. The negative electrode is made of zinc foil, cut into a size of 1 cm*1 cm, and drawn out with nickel wire to form the negative electrode. Electrolyte is 1 M Zn 2 SO 4 solution, assembled into an aqueous zinc-ion battery. The assembled aqueous Zn-ion battery was charged and discharged on the electrochemical workstation (PARSTA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com