A kind of porous silicon/graphene composite material and its preparation method and application

A technology of composite materials and porous silicon, applied in structural parts, electrical components, battery electrodes, etc., can solve problems such as poor electronic conductivity and severe volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

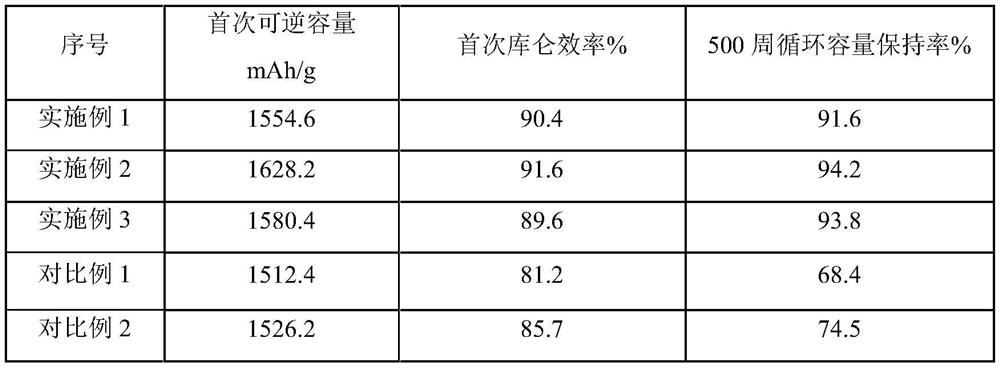

Examples

Embodiment 1

[0061] 1. 1L mass fraction of 5.4% Ca(OH) 2 Add the suspension into the reaction vessel, stir the suspension at a rotation speed of 300r / min, add 1.5g of SBA-15 particles after 10min, start the vacuum pump to make the vacuum of the reaction vessel reach -0.06MPa, and turn off the vacuum pump. After continuing to stir for 30 min, CO was introduced into the 2 gas, when H is 7, stop feeding the reaction gas, filter the suspension, and dry it under vacuum at 70°C for 6 hours to obtain a porous silica / calcium carbonate composite material.

[0062] 2. Mix 4 g of porous silica / calcium carbonate composite material with 1 g of polyacrylonitrile in 2 L of dimethyl sulfoxide (DMSO) solvent, and heat to remove the solvent to obtain an organic-coated porous silica / calcium carbonate composite material.

[0063] 3. Mix 1g of organic-coated porous silica / calcium carbonate composite material with 1g of magnesium powder, put it in the muffle furnace, first pass pure argon for 30min, and the fl...

Embodiment 2

[0066] 1. 1L mass fraction of 5.4% Ca(OH) 2 Add the suspension into the reaction vessel, stir the suspension at a rotation speed of 400r / min, add 2.5g of MCM-48 particles after 20min, start the vacuum pump to make the vacuum of the reaction vessel reach -0.06MPa, and turn off the vacuum pump. After continuing to stir for 40 min, CO 2 gas, when the pH is 6, stop feeding the reaction gas, filter the suspension, and dry it in a vacuum environment at 80°C for 7 hours to obtain a porous silica / calcium carbonate composite material.

[0067] 2. Mix 5g of porous silica / calcium carbonate composite with 1g of polyacrylonitrile in 2L nitrogen dimethylformamide (DMF) solvent, heat to remove solvent to obtain organic carbon-coated porous silica / calcium carbonate composite .

[0068] 3. Mix 1g of organic-coated porous silica / calcium carbonate composite material with 1g of magnesium powder, put it in the muffle furnace, first pass pure argon gas for 20min, the flow rate is 300ml / min, and r...

Embodiment 3

[0071] 1. 1L mass fraction of 5.4% Ca(OH) 2 Add the suspension into the reaction vessel, stir the suspension at a rotation speed of 400r / min, add 3.0g of purified diatomite particles after 20min, start the vacuum pump to make the vacuum of the reaction vessel reach -0.06MPa, and turn off the vacuum pump. After continuing to stir for 40 min, CO 2 gas, when the pH is 8, stop feeding the reaction gas, filter the suspension, and dry it in a vacuum environment at 80° C. for 5 hours to obtain a porous silica / calcium carbonate composite material.

[0072] 2. Mix 3 g of porous silica / calcium carbonate composite material with 1 g of polyacrylonitrile in 2 L of dimethylacetamide (DMAC) solvent, and remove the solvent by heating to obtain organic carbon-coated porous silica / calcium carbonate composite material.

[0073] 3. Mix 1g of organic-coated porous silica / calcium carbonate composite material with 1.1g of magnesium powder, place it in a muffle furnace, and feed pure argon for 30 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com