Water stop belt and deformation joint waterproof structure

A technology of waterproof structures and waterstops, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as insufficient extensiveness, weak tensile and twisting deformation capabilities, and corrosion of steel edges. Achieve high elasticity, avoid fatigue aging and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described below.

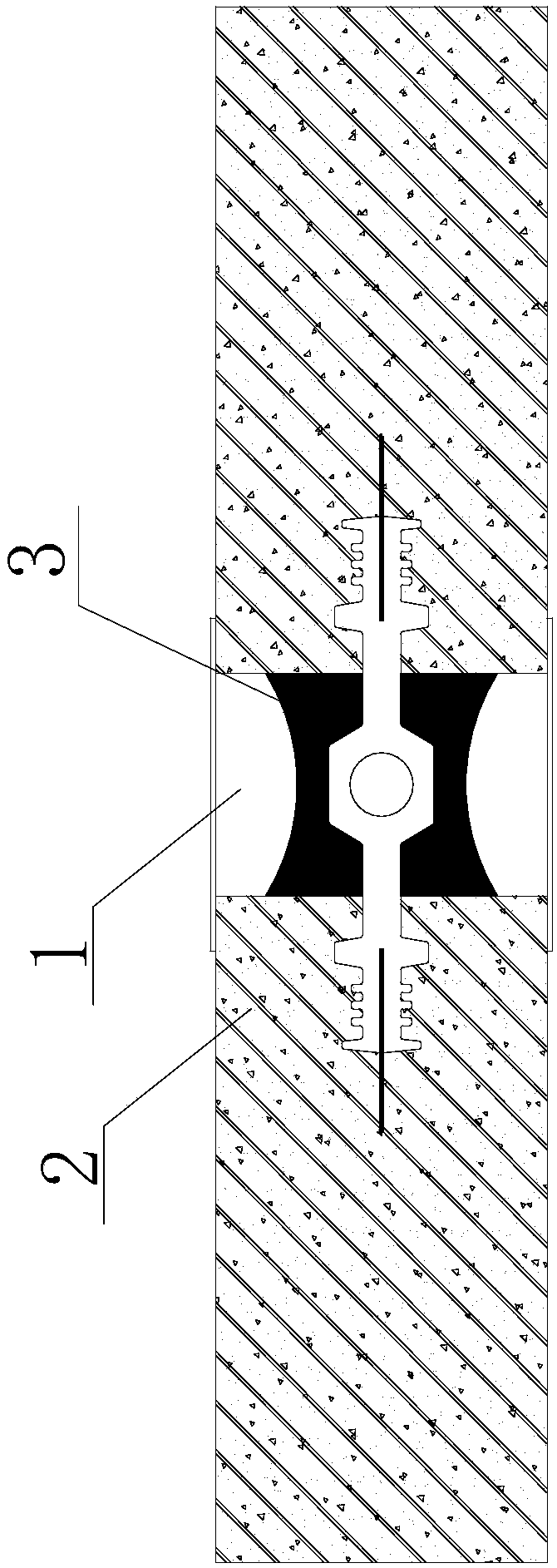

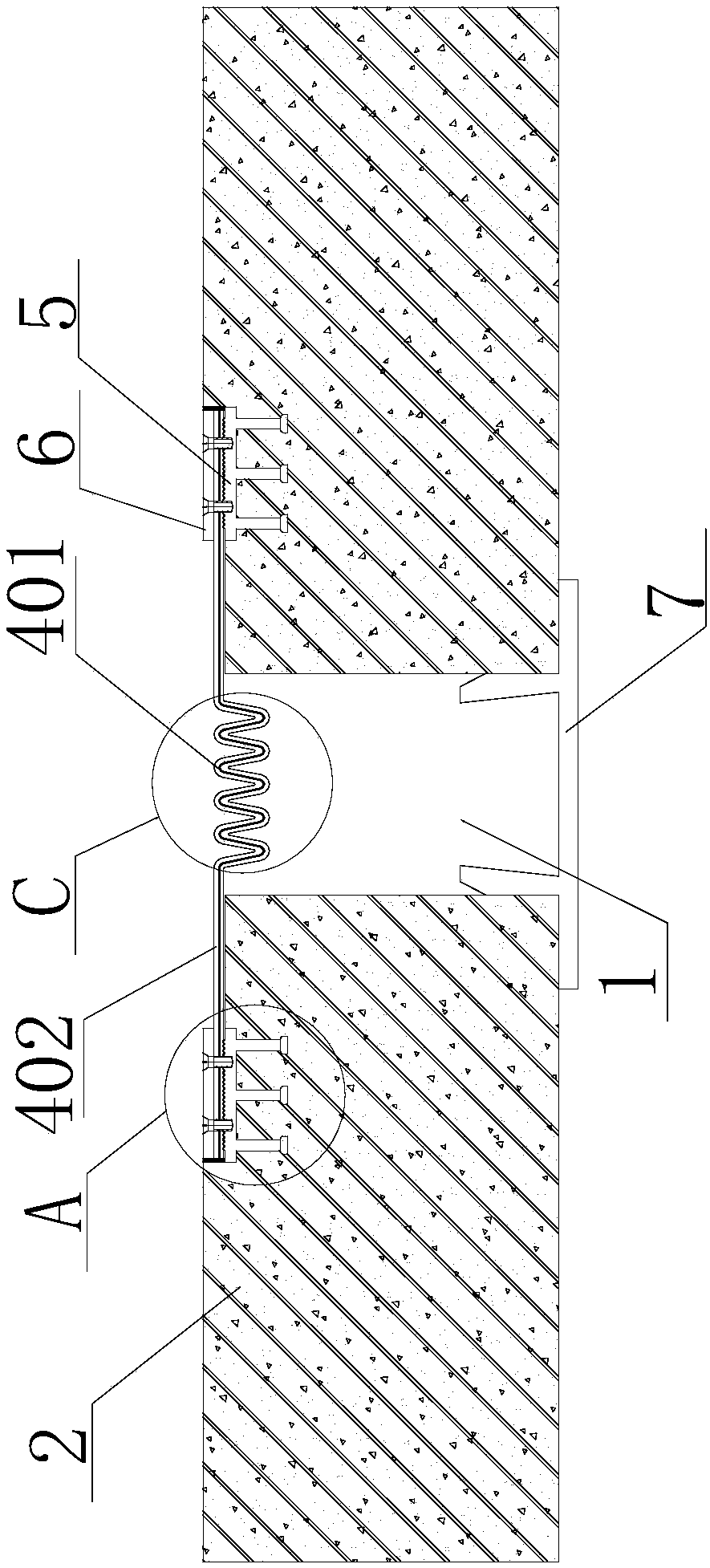

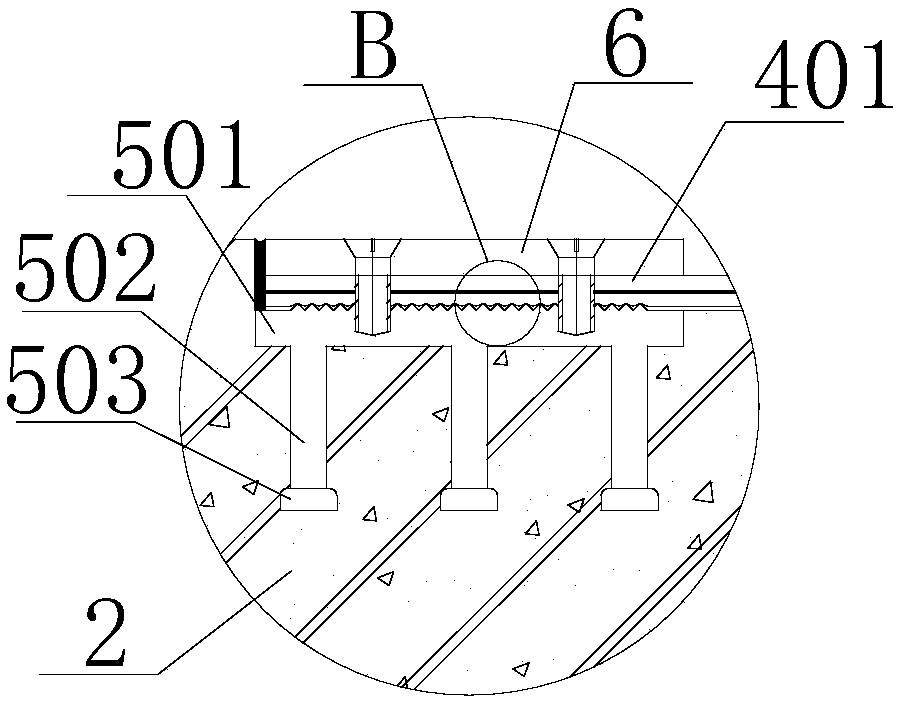

[0035] The waterstop disclosed in the present invention includes a waterproof layer 401 and an inner lining layer 402 along the thickness direction, and at least one side of the inner lining layer 402 is covered with the waterproof layer 401; along the width direction, it includes a stretchable part 403 in the middle and The connecting portion 404 located on both sides, the stretchable portion 403 is folded to form a stretchable structure, and the strength and rigidity of the material of the inner lining layer 402 are greater than that of the waterproof layer 401 .

[0036] Such as figure 2 As shown, when using the waterstop, connect the connecting parts 404 on both sides to the concrete structures 2 on both sides of the deformation joint 1, so that the waterstop covers the entire deformation joint 1 to achieve waterproof effect; the expansion and contraction of the waterstop The part 403 is located between the concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com