Petroleum sodium sulfonate composition as well as preparation method and application thereof

A technology of sodium petroleum sulfonate and composition, which is applied in drilling compositions, chemical instruments and methods, earth-moving drilling and other directions, can solve the problem of increasing difficulty in water treatment of produced fluid, increasing polymer concentration, and increasing oil displacement. Solving problems such as the cost of reagents, and achieving the effect of being conducive to industrialized continuous production, reducing the oil-water interfacial tension, and simplifying the synthesis reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

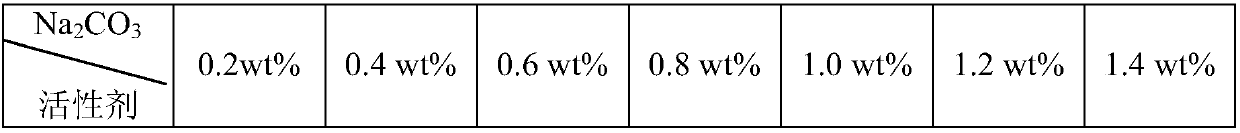

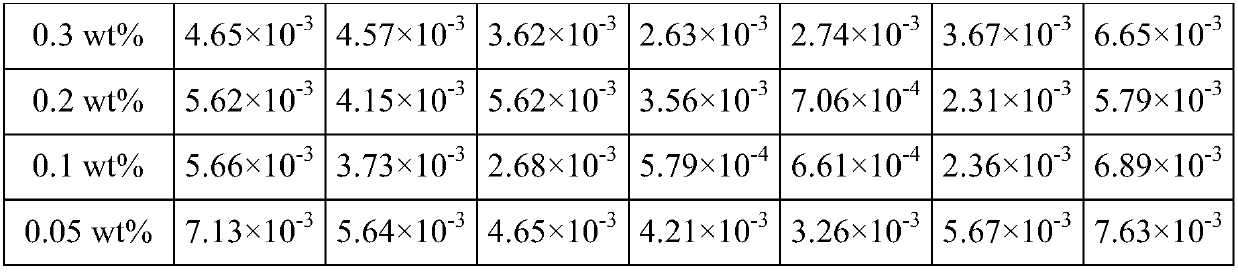

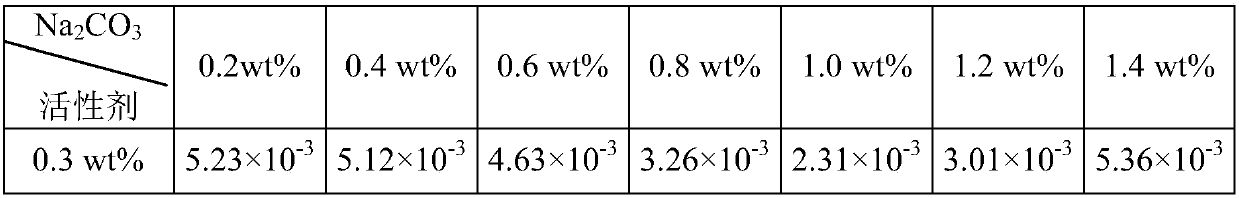

Examples

Embodiment 1

[0046] Present embodiment provides a kind of preparation method of petroleum sulfonic acid sodium salt composition, it comprises the following steps:

[0047] In this example, the second-line and third-line dewaxed dewaxed oils of the Dalian Petrochemical Plant are used as raw materials. Based on the total weight of the mixture as 100%, it contains 65wt% of the second-line dewaxed dewaxed oil and 35wt% of the dewaxed oil of the second line of decompression. Vacuum three-line reverse sequence dewaxed oil, and the content of aromatics in the mixture is 30wt%-32wt%;

[0048] SO 3 Membrane sulfonation reaction (realized in membrane sulfonation reactor) temperature is 50-60 ° C, SO 3 The volume concentration of the gas is 5%-6%, n-butanol is the diluent, and the consumption is 1wt%;

[0049] Neutralize with 25wt% NaOH solution to make the product pH value reach 8-9, and the homogeneous product obtained is sodium petroleum sulfonate surfactant (active substance effective content a...

Embodiment 2

[0058] Present embodiment provides a kind of preparation method of petroleum sulfonic acid sodium salt composition, it comprises the following steps:

[0059] In this example, the second decompression line, the third decompression line reverse sequence dewaxed oil and the second decompression line furfural oil extracted from Dalian Petrochemical Plant are used as raw materials. Based on the total weight of the mixture as 100%, it contains 50 wt% of the second decompression line reverse sequence dewaxing oil. Dewaxed oil, 30wt% vacuum third-line reverse sequence dewaxed oil and 20wt% vacuum second-line furfural extraction oil, and the content of aromatics in the mixture is 38wt%-42wt%;

[0060] SO 3 The sulfonation reaction temperature is 65-70°C, SO 3 The volume concentration of the gas is 7%-9%, n-butanol is the diluent, and the consumption is 2wt%.

[0061] Neutralize with 20wt% NaOH solution to make the product pH value reach 9-10, and the homogeneous product obtained is ...

Embodiment 3

[0070] Present embodiment provides a kind of preparation method of petroleum sulfonic acid sodium salt composition, it comprises the following steps:

[0071] In this example, the dewaxed dewaxed oil from the second decompression line, the third decompression line decompression line and the furfural extracted oil from the decompression second line decompression line of Dalian Petrochemical Plant are used as raw materials. Based on the total weight of the mixture as 100%, it contains 45wt% of the decompression second line reverse sequence dewaxing oil. Dewaxed oil, 45wt% vacuum third-line reverse sequence dewaxed oil and 10wt% vacuum second-line furfural extracted oil, and the content of aromatics in the mixture is 34wt%-37wt%;

[0072] SO 3 The sulfonation reaction temperature is 65-70°C, SO 3 The volume concentration of the gas is 6%-7%, n-octanol is the diluent, and the consumption is 1.2wt%.

[0073] Neutralize with 25wt% NaOH solution to make the product pH 8-9, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com