Ship with self-energy storing, gas combustion cool and thermal power based on vanadium cell

A technology of combined cooling, heating and power supply and ship installations, which is applied in gas turbine installations, fuel cell heat exchange, ship propulsion, etc., can solve the problems of high energy consumption, serious pollution, and loud noise, and achieve energy saving, energy efficiency, low noise, The effect of increased efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

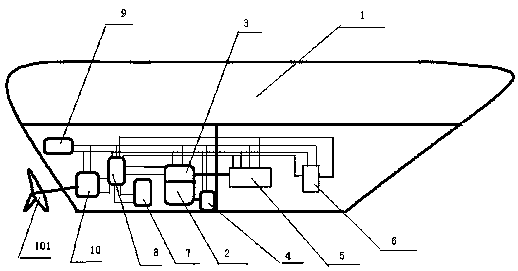

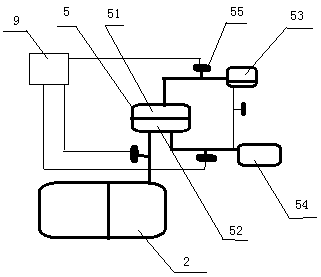

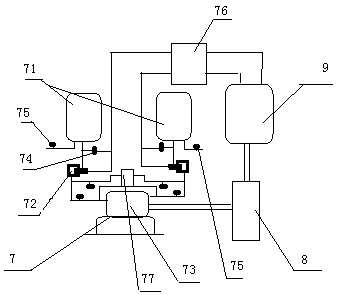

[0032] like figure 1 , figure 2 , image 3 As shown, in this embodiment, all the energy supply of the ship system adopts the gas turbine power generation system. The specific embodiment, the central control unit 9 is started, the gas output geomagnetic valve of the gas storage tank 4 of the gas turbine system is opened, the gas flows into the combustion chamber 2 of the gas turbine to start the gas turbine and drives the gas power generation unit, and the power generated by the gas power generation unit 3 is passed through the inverter. The control unit 8 outputs to the vanadium liquid battery energy storage unit 7, and the power output terminal of the vanadium liquid battery energy storage unit 7 outputs the power to the reluctance motor power unit 10 through the variable current control unit 8, drives the ship propeller 11, and pushes the ship to run. The power output end of the vanadium liquid battery energy storage unit 7 outputs power to the auxiliary energy-consuming ...

Embodiment 2

[0034] like figure 1 , image 3 As shown, in the present embodiment, the vanadium liquid battery energy storage unit directly supplies power to the ship system, the central control unit 9 starts, the vanadium liquid battery energy storage unit 7 system starts, and the vanadium liquid battery energy storage unit 7 converts the power through the inverter control unit 10. Output to the reluctance motor power unit 10 to drive the ship propeller 11 to push the ship to run. When the vanadium liquid battery energy storage unit 7 is out of power, the vanadium liquid battery energy storage unit 7 is charged from the commercial power to the vanadium liquid battery energy storage unit 7 through the mains charging port of the inverter control unit 8 . In this embodiment, the electrolyte in the electrolyte tank 71 can also be replaced through the electrolyte inlet and outlet pipe 75 of the energy storage unit 7 of the vanadium liquid battery to achieve the purpose of charging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com