Air curtain type heat-insulation and heat-equalizing structure for fiber pipeline winding forming machine

A technology of fiber pipes and molding machines, which is applied to tubular objects, other household appliances, household appliances, etc., and can solve the problems of uneven heating, cracking and bonding of composite sheets, pipe deformation, etc., and achieve good heat insulation and heat uniformity effects , improve uniformity and avoid deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

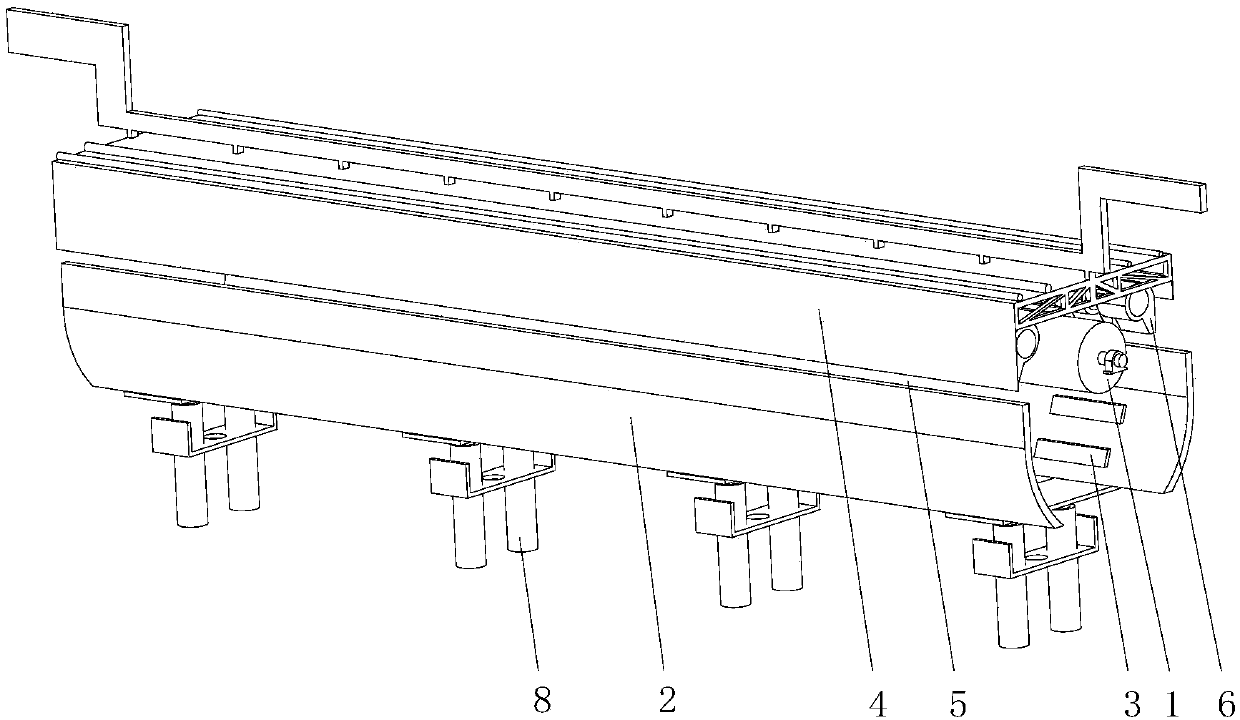

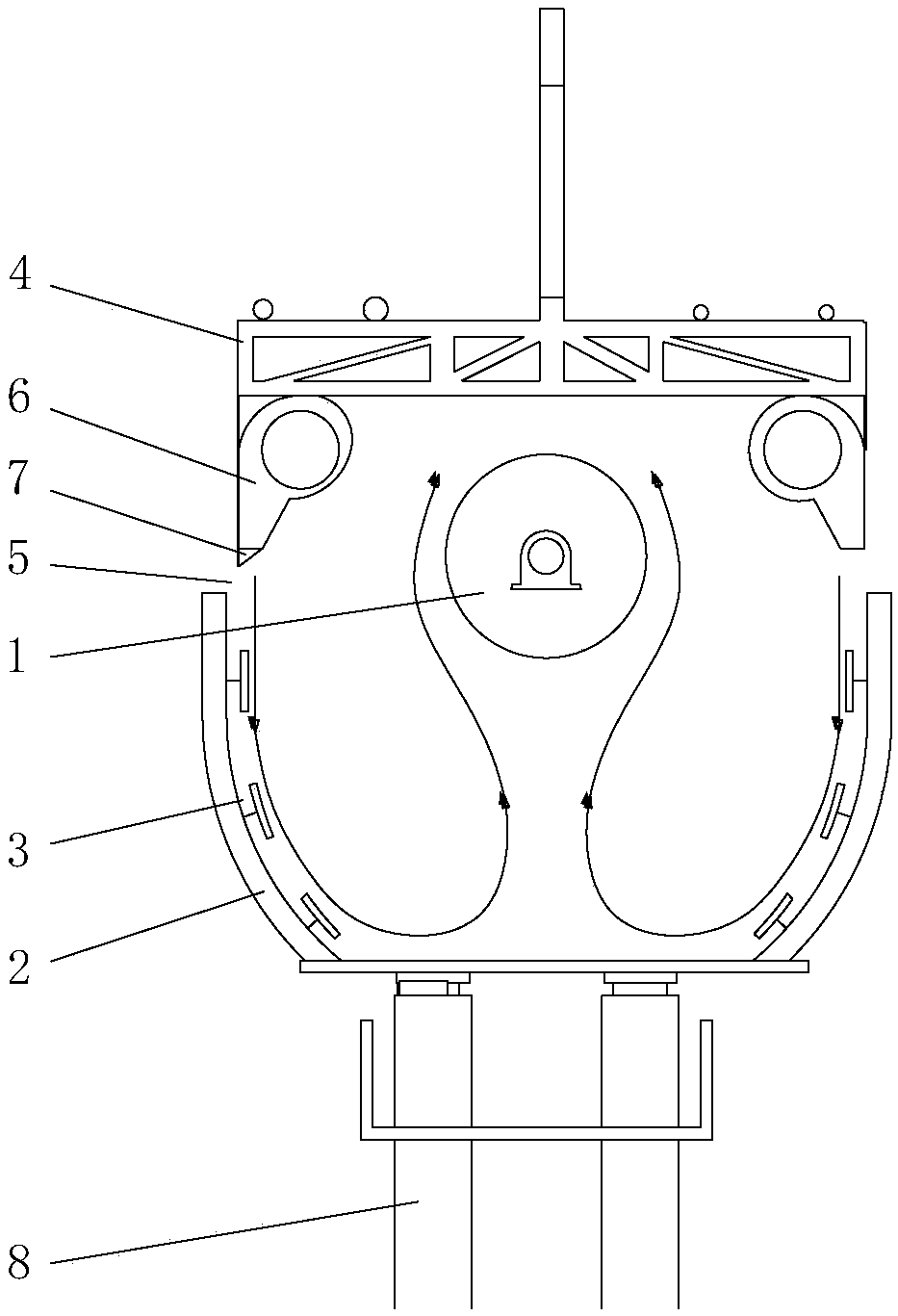

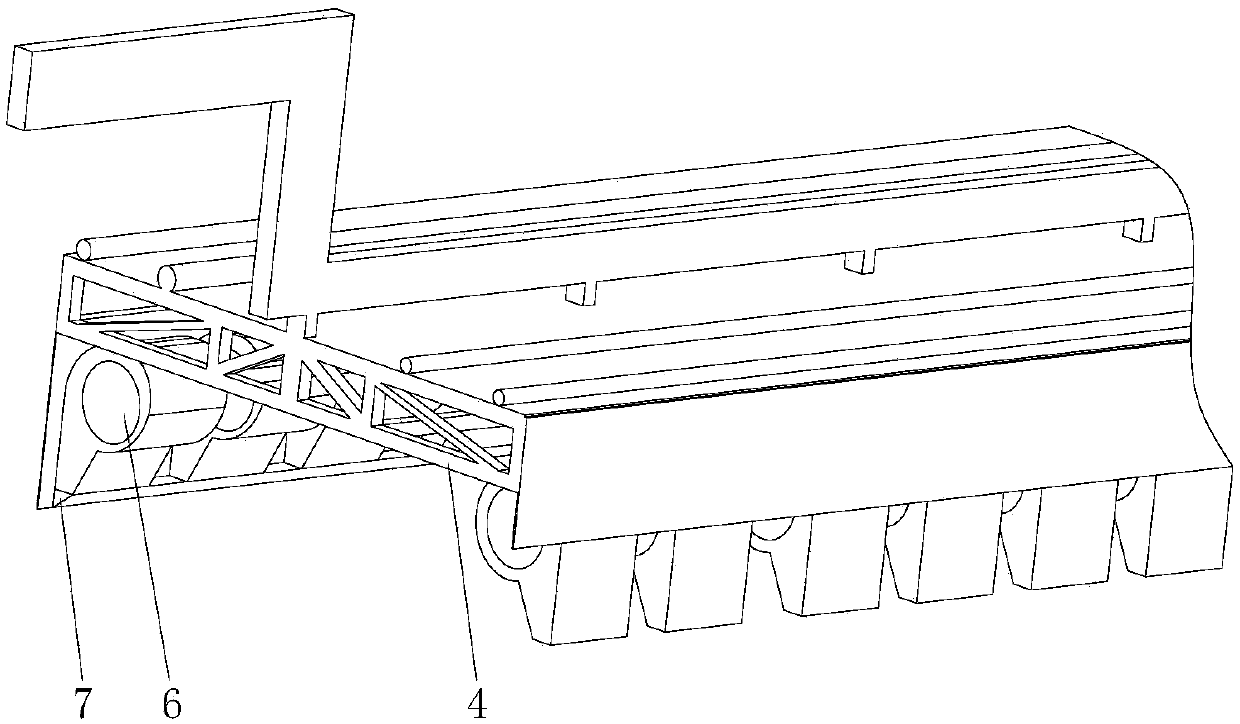

[0020] like Figure 1-3 As shown in one of the above, the air curtain type heat insulation and uniform heat structure of the fiber pipe winding molding machine of the present invention includes a long strip-shaped heating furnace body 2 arranged on the side of the mold axis 1 of the fiber pipe winding molding machine. 2 is provided with a number of heating plates 3 arranged along the length direction of the heating furnace body. The top of the heating furnace body 2 is provided with a furnace mouth (not marked in the figure), and a furnace cover 4 is suspended above the furnace mouth. Openings 5 are respectively formed between the two sides of the cover 4 and the two sides of the heating furnace body 2. A row of fans 6 with the air outlet facing downwards are respectively arranged on both sides of the cover 4 along its length direction, and the two rows of fans 6 respectively form a longitudinal Blow into the air curtain in the heating furnace body 2.

[0021] Further, at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com