Automobile diesel fuel pump fuel tank cap detaching device

A fuel pump and fuel tank cap technology is applied in the field of automobile diesel fuel pump fuel tank cap disassembly and assembly device, which can solve the problems of low disassembly and assembly efficiency of fuel pump fuel tank cap, and achieve the effects of improving use safety, convenient use and novel design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

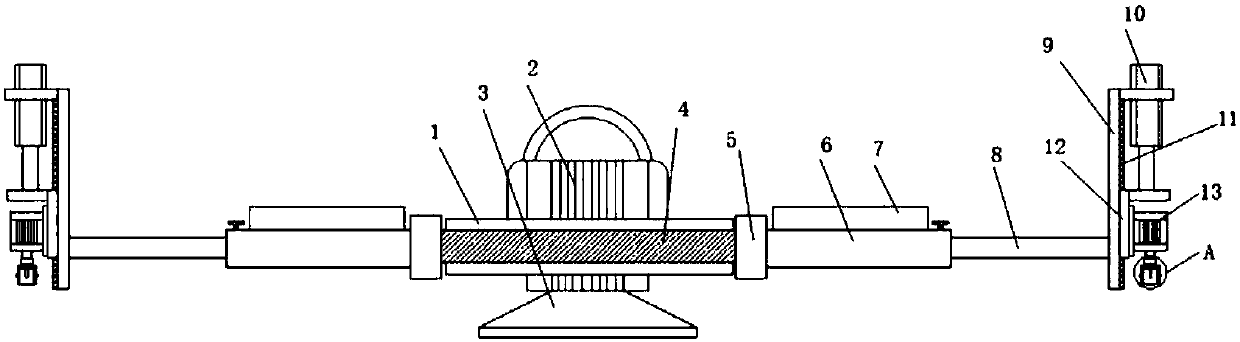

[0030] refer to Figure 1-6 , an automobile diesel fuel pump fuel tank cap remover, including a support chassis 1, the support chassis 1 is provided with a control device, and the control device is electrically connected with a vacuum air pump 2, a lifting cylinder 10 and a forward and reverse motor 13, and the support chassis 1 is Disc-shaped structure, and a vacuum pump 2 is installed at the center of the support chassis 1, a vacuum suction cup 3 is provided on one side of the support chassis 1, and the vacuum suction cup 3 is connected with the vacuum pump 2, and a sliding ring is provided on the side of the support chassis 1. Track 4, sliding block 5 is movable installed on the sliding track 4, and sliding block 5 is fixedly connected with one end of support arm 6, and support arm 6 is arranged along the radial direction of support chassis 1, and the upper side of support arm 6 is provided with storage along the length direction. The box 7 and the support arm 6 are hollow ...

Embodiment 2

[0034] refer to Figure 4The storage box 7 is fixedly welded on the support arm 6 along the length direction of the support arm 6, and the upper side of the storage box 7 is hinged with a storage cover 71, and the inner side walls of the storage box 7 are equidistantly provided with clips along the length direction. Spring 72 is tightened, and every two groups of clamping springs 72 on the same side are fixedly connected to the outer arc side of the arc splint 73, and the arc splint 73 on the inner wall on both sides of the storage box 7 is clamped with disassembly Head 19, and dismounting head 19 is provided with corresponding specifications 4-10 according to the specifications and sizes of fuel pump fuel tank cap locking bolts, and a plurality of dismounting heads 19 of different specifications are arranged in storage box 7, can adapt to fuel pump The disassembly and assembly of locking screws of different specifications on the fuel tank cover is convenient for the storage a...

Embodiment 3

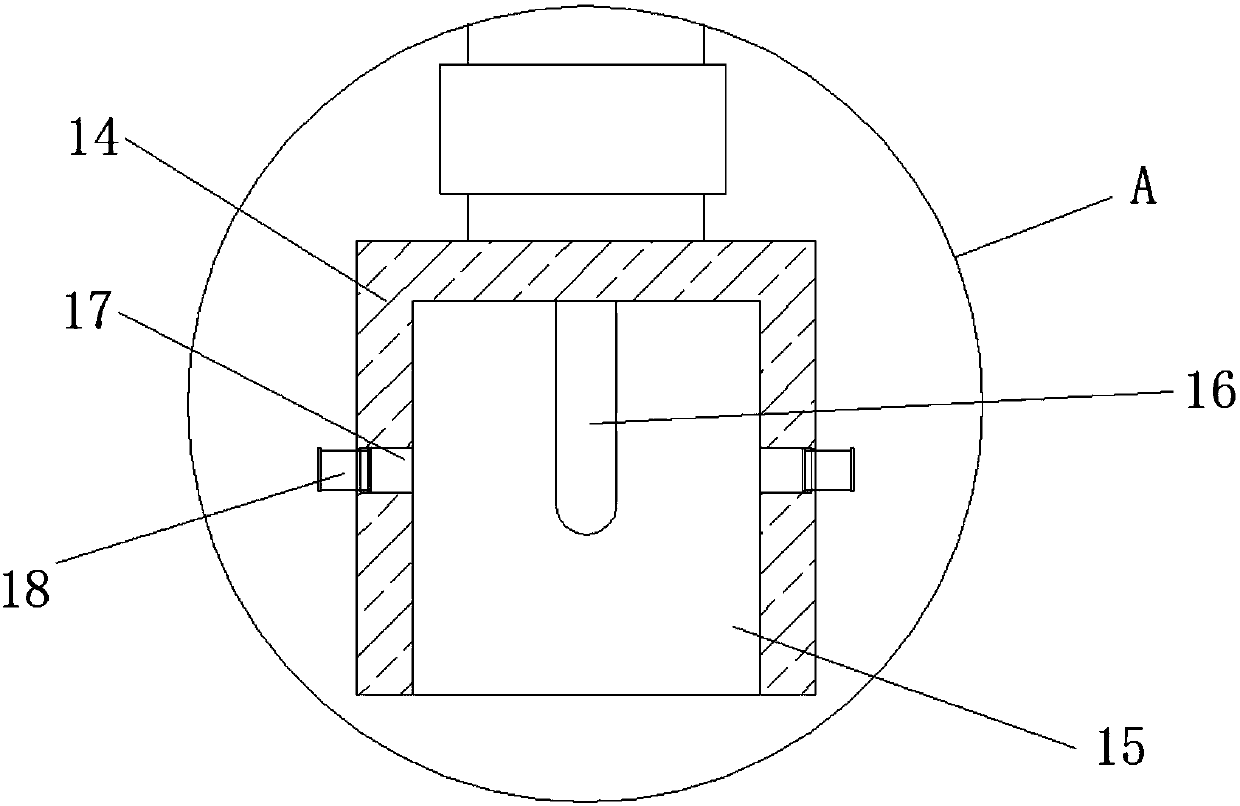

[0036] refer to figure 2 , 5 Or 6, the connector 14 is a cylindrical hollow structure, and one end is fixedly connected to the output shaft of the forward and reverse motor 13, and the end away from the forward and reverse motor 13 is set as an opening, and the connector 14 is connected to the forward and reverse motor 13 A guide column 16 is arranged at the inner circle center of one end, and the side wall of the connector 14 is symmetrically provided with a clamping hole 17 that runs through the side wall, and a retracting rod 18 is movably installed in the clamping hole 17, and one end of the retracting rod 18 passes through the clamping hole 17. The connecting hole 17 extends to the outside of the connecting head 14, the center of the dismounting head 19 is provided with a docking channel 20, and the docking channel 20 is docked with the guide column 16, and the two sides of the disassembling head 19 are symmetrically provided with telescopic grooves, and A clamping spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com