Reinforced poly(phenylene ether) compositions, and articles prepared therefrom

A technology of phenylene ether and composition, applied in the field of reinforced poly(phenylene ether) composition and products prepared therefrom, can solve the problems of reducing the flame retardancy of the composition and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

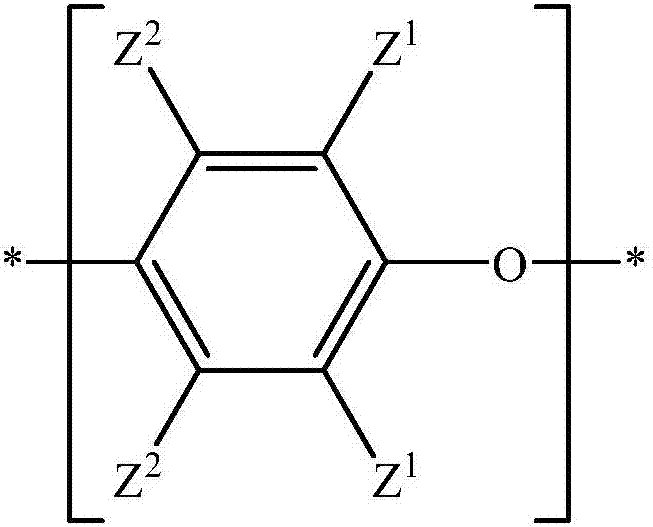

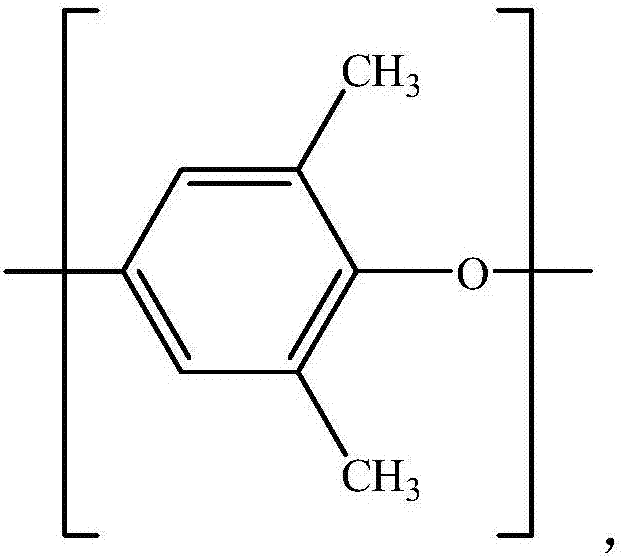

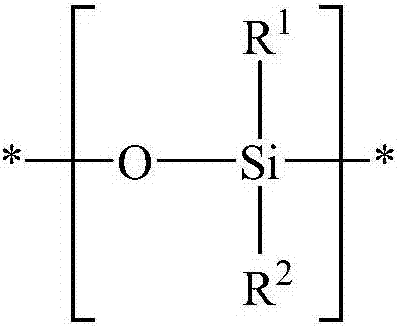

[0086] Embodiment 1: A composition, based on the total weight of polymer and filler, comprising: 0.5 to 91 weight percent of a poly(phenylene ether) and poly(phenylene ether)-polysiloxane intercalated Poly(phenylene ether)-polysiloxane block copolymer reaction product of segment copolymer, 1 to 50 weight percent homopolystyrene; 3 to 25 weight percent comprising organophosphate, phosphazene, or combinations thereof flame retardant; and 5 to 40 weight percent reinforcing filler.

Embodiment approach 2

[0087] Embodiment 2: The composition of Embodiment 1, further comprising 5 to 90.5 weight percent of a second poly(phenylene ether).

Embodiment approach 3

[0088] Embodiment 3: the composition of Embodiment 1, comprising 2 to 20 weight percent of the poly(phenylene ether)-polysiloxane block copolymer reaction product and 10 to 60 weight percent of the second poly(phenylene ether).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com