Production method of garbage incineration ash residue-containing microbial brick

A technology of waste incineration ash and production method, which is applied in the field of solid waste resource utilization, can solve the problems of harmful gas emission process, poor engineering performance and high energy consumption, achieve good environmental protection and economic benefits, improve strength performance, reduce high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] In this example, a method for making a waste incineration ash microbial brick, the method comprises the following steps:

[0034] a. Sieve the waste incineration ash, and take the waste incineration ash with a particle size of less than 5mm and the concentration as OD 600 = 1.2 of the bacterial solution was mixed evenly;

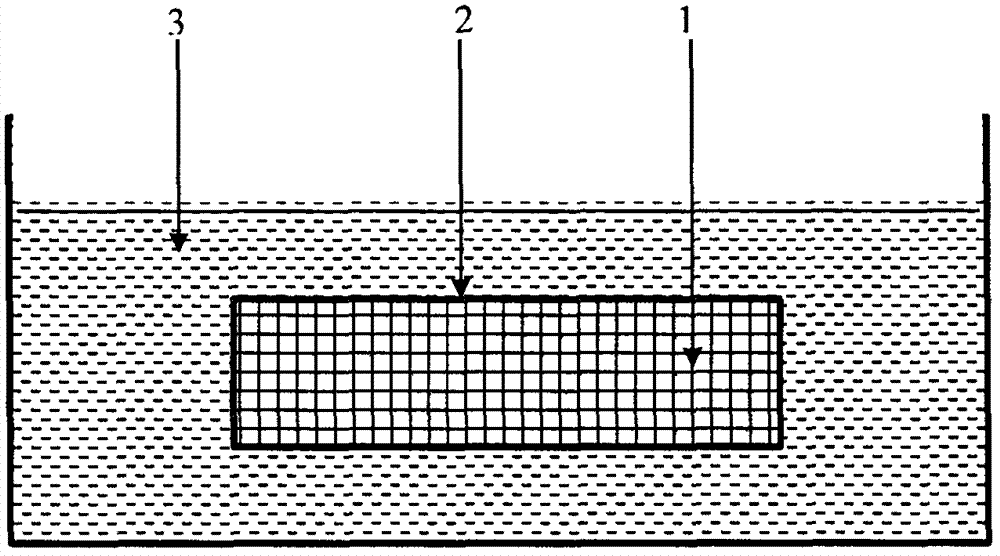

[0035] b. The garbage incineration ash 1 mixed with the bacteria liquid is packed into a porous water-permeable mold 2 for compaction;

[0036] c. Submerge the porous water-permeable mold 2 containing the garbage incineration ash 1 in the mixed salt solution 3 with a concentration of 0.8mol / L, so that the mixed salt solution 3 penetrates into the pores of the garbage incineration ash 2, and let it stand for 12 hours;

[0037] d. Take out the porous water-permeable mold 3 containing the garbage incineration ash 1 from the mixed salt solution 3, and drain the free liquid in the pores of the garbage incineration ash 1;

[0038] e. Repeat operations c a...

Embodiment 2

[0040] In this example, a method for making a waste incineration ash microbial brick, the method comprises the following steps:

[0041] a. Sieve the waste incineration ash, and take the waste incineration ash with a particle size of less than 5mm and the concentration as OD 600 = 1.2 of the bacterial solution was mixed evenly;

[0042] b. The garbage incineration ash 1 mixed with the bacteria liquid is packed into a porous water-permeable mold 2 for compaction;

[0043] c. Immerse the porous water-permeable mold 2 containing the garbage incineration ash 1 in the mixed salt solution 3 with a concentration of 1.2mol / L, so that the mixed salt solution 3 penetrates into the pores of the garbage incineration ash 2, and let it stand for 12 hours;

[0044] d. Take out the porous water-permeable mold 2 containing the waste incineration ash 1 from the mixed salt solution 3, and drain the free liquid in the pores of the waste incineration ash 1;

[0045] e. Repeat operations c and d ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com