Processing method of quickly-ripe low-sodium-salt dry-cured ham

A dry-cured ham and processing method technology, applied in the field of low-sodium dry-cured ham processing, can solve the problems of weak ability to resist market changes, inconsistent product quality, lack of scientific management, etc., and achieve product quality and safety guarantee , increase the burden and potential risks of the enterprise, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Raw material selection: choose fresh and healthy pork legs with no damage, no wounds, no broken bones, no dislocations, full and bright red leg muscles, and a weight of 13-14 kg;

[0038] (2) Trimming: According to the traditional method, the pork legs are boned, cut open, trimmed the sides of the legs, squeezed blood, and finally trimmed into a pipa shape;

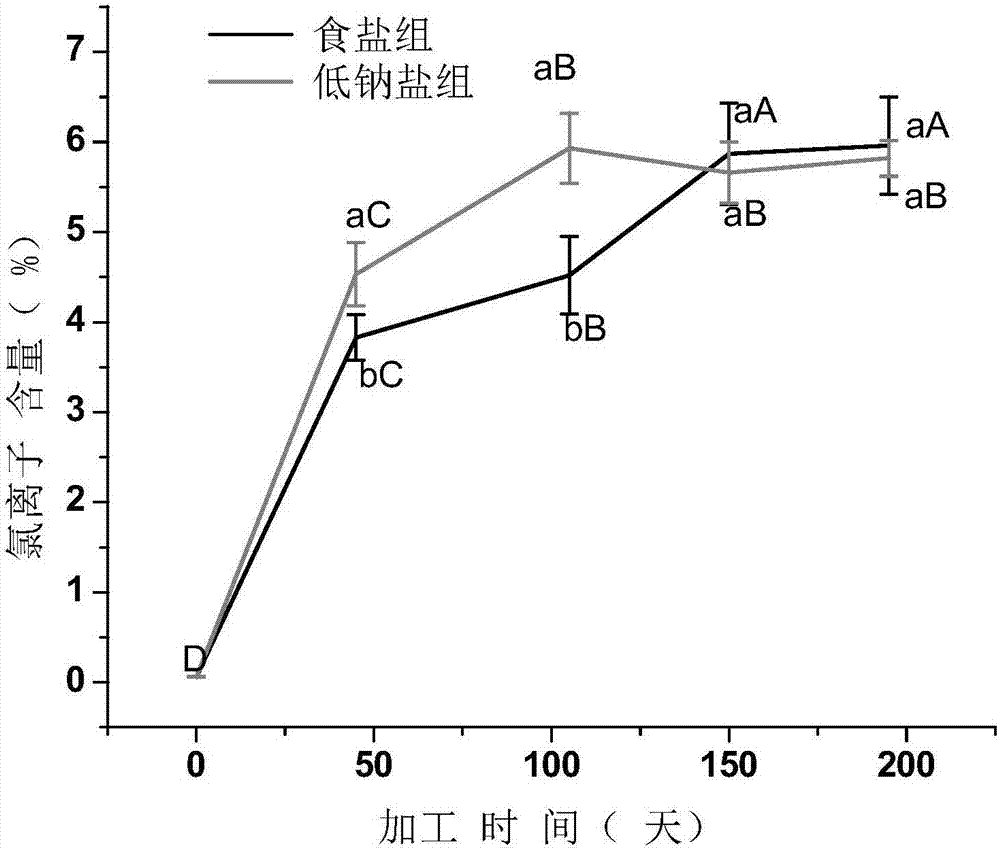

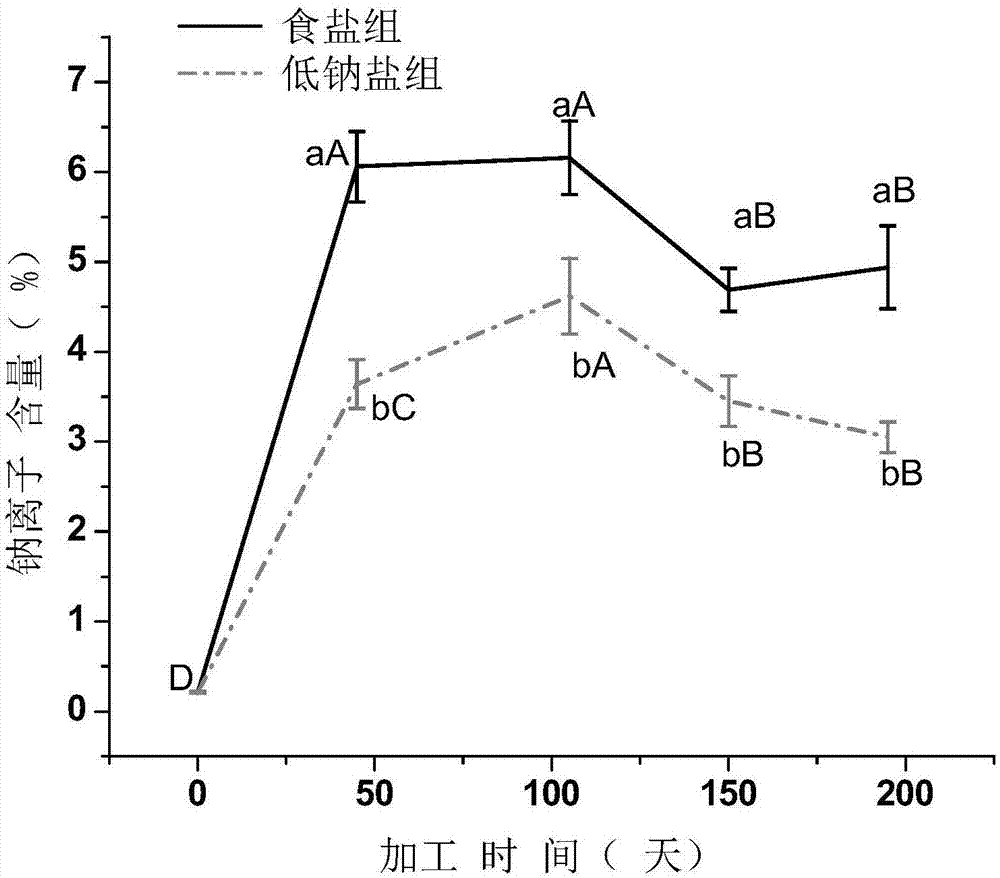

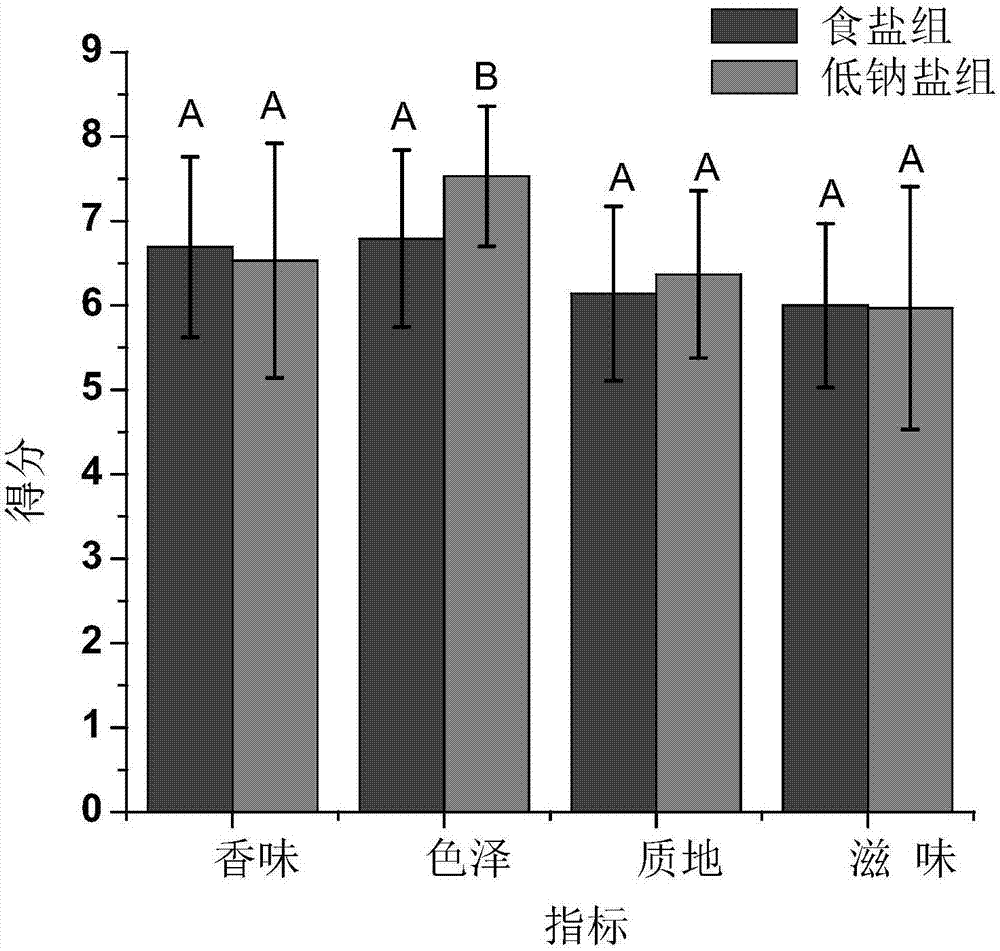

[0039] (3) Curing: replace 50% (w / w) sodium chloride with potassium chloride and mix evenly to make low-sodium salt, add low-sodium salt according to 8% of fresh leg weight, add salt in 6 times, The temperature is controlled at 2-4°C, the relative humidity is controlled at 90%-95%, and the curing time is 45 days. The amount of salt used for the first time is 20% of the total amount of salt used; the second salt is added 24 hours after the first salt is added, and the amount of salt added is 40% of the total amount of salt used; The ham is placed on a special crawler massage machine, squeezed or massaged by rel...

Embodiment 2

[0048] (1) Raw material selection: choose fresh and healthy pork legs with no damage, no wounds, no broken bones, no dislocations, full and bright red leg muscles, and a weight of 9-10 kg;

[0049] (2) Trimming: According to the traditional method, the pork legs are boned, cut open, trimmed the sides of the legs, squeezed blood, and finally trimmed into a pipa shape;

[0050] (3) Pickling: Substitute 50% (w / w) sodium chloride with potassium chloride and mix evenly to make low-sodium salt, add low-sodium salt according to 6% of fresh leg weight, add salt in 5 times, The temperature is controlled at 2-4°C, the relative humidity is controlled at 90%-95%, and the curing time is 30 days. The amount of salt used for the first time is 25% of the total amount of salt used; the second salt is added 24 hours after the first salt is added, and the amount of salt added is 40% of the total amount of salt used; The ham is placed on a special crawler massage machine, squeezed or massaged by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com