STEREOLlTHOGRAPHY MACHINE WITH IMPROVED OPTICAL UNIT

A stereo light curing, optical unit technology, applied in optical components, optics, opto-mechanical equipment, etc., can solve the problem of mirror size limitation, low production time, large inertial momentum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

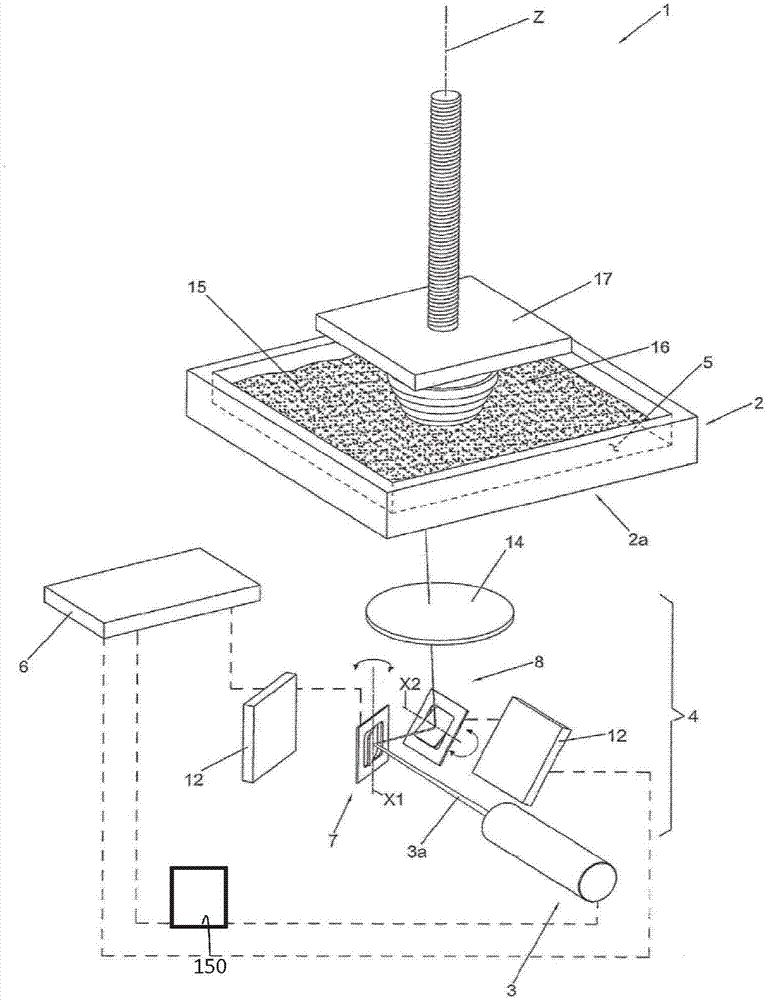

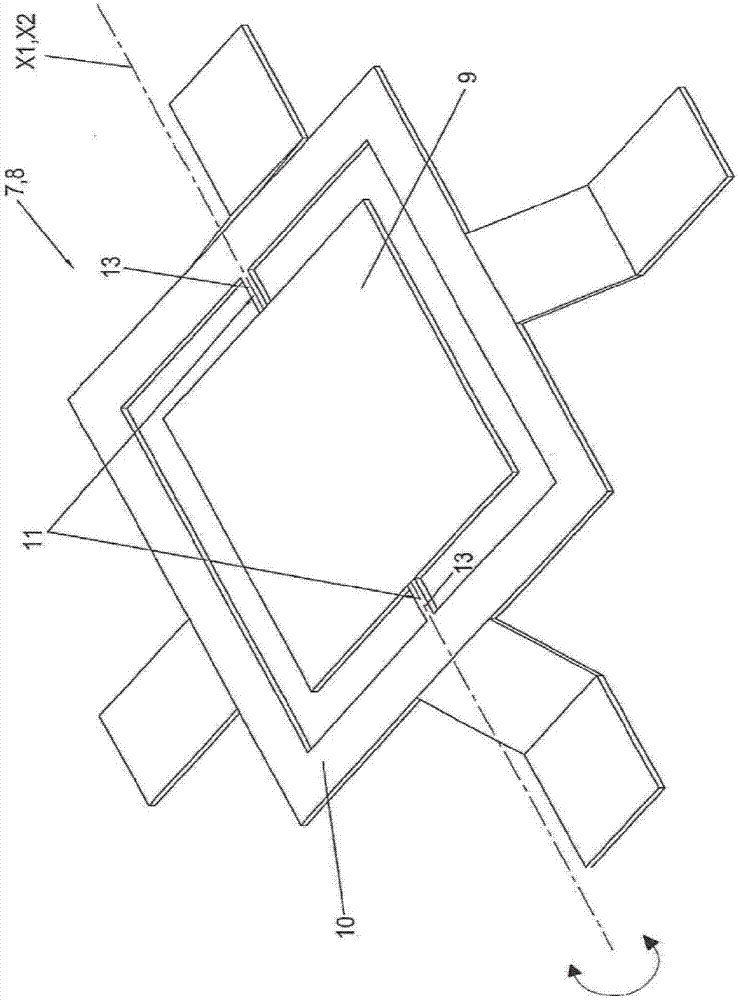

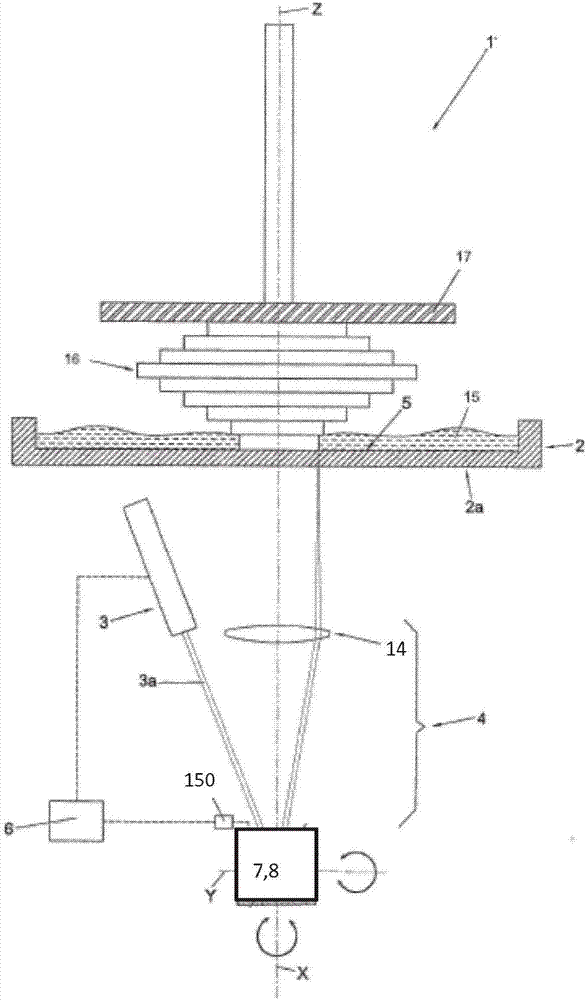

[0082] The stereolithography machine that is the subject of the present invention, in figure 1 and image 3 In the whole, it is represented by 1, and can be stacked by multiple layers ( image 3 The process seen in ) produces a three-dimensional object 16, said layers being obtained by selectively exposing a fluid substance 15 to predetermined radiation 3a suitable for curing it.

[0083] Preferably, the fluid substance 15 is a photosensitive liquid resin. Preferably, the resin is a polymeric resin curable using radiation in the UV range. Preferably, the resin comprises:

[0084] (Meth)acrylated monomers and / or oligomers further comprising photosensitizers and / or colorants and, in some cases, fillers.

[0085] Radiation for exposing the fluid substance is emitted by the laser source 3, preferably radiation in the wavelength range of violet wavelengths (eg 405nm±10nm). When a laser beam of a given irradiance hits the resin, the above-mentioned resin is solidified. Prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com