Article manufacturing apparatus and manufacturing method

A technology for manufacturing devices and articles, applied in manufacturing tools, semiconductor/solid-state device manufacturing, molding tools, etc., can solve the problems of RFID tag damage and inapplicability, and achieve the effect of suppressing bad effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

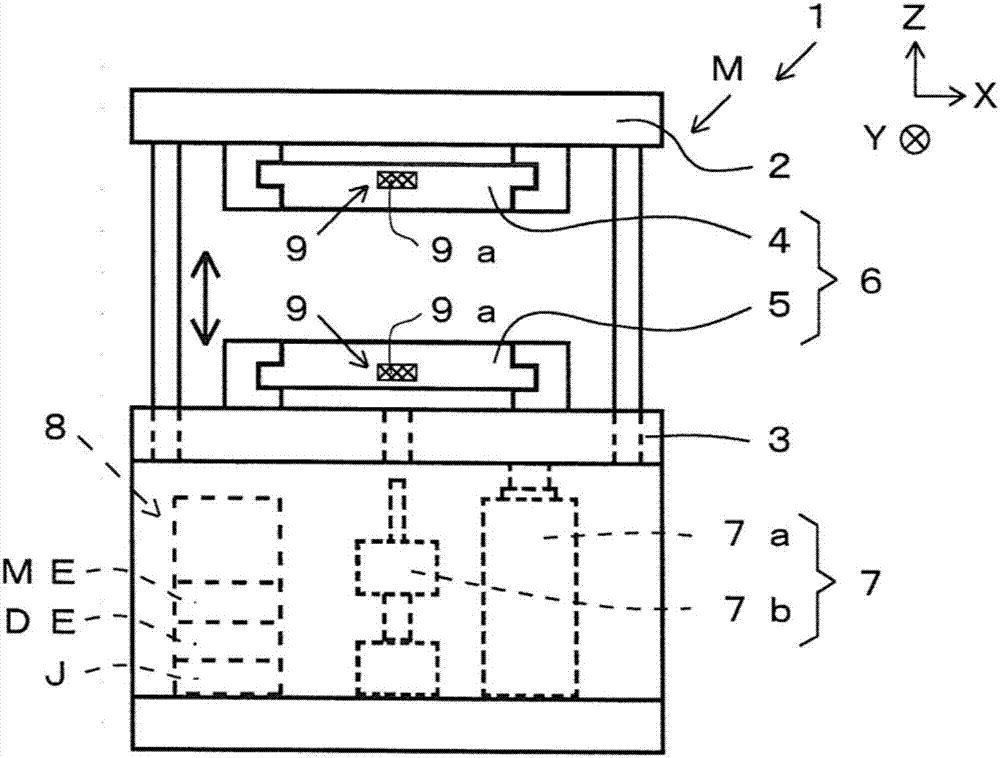

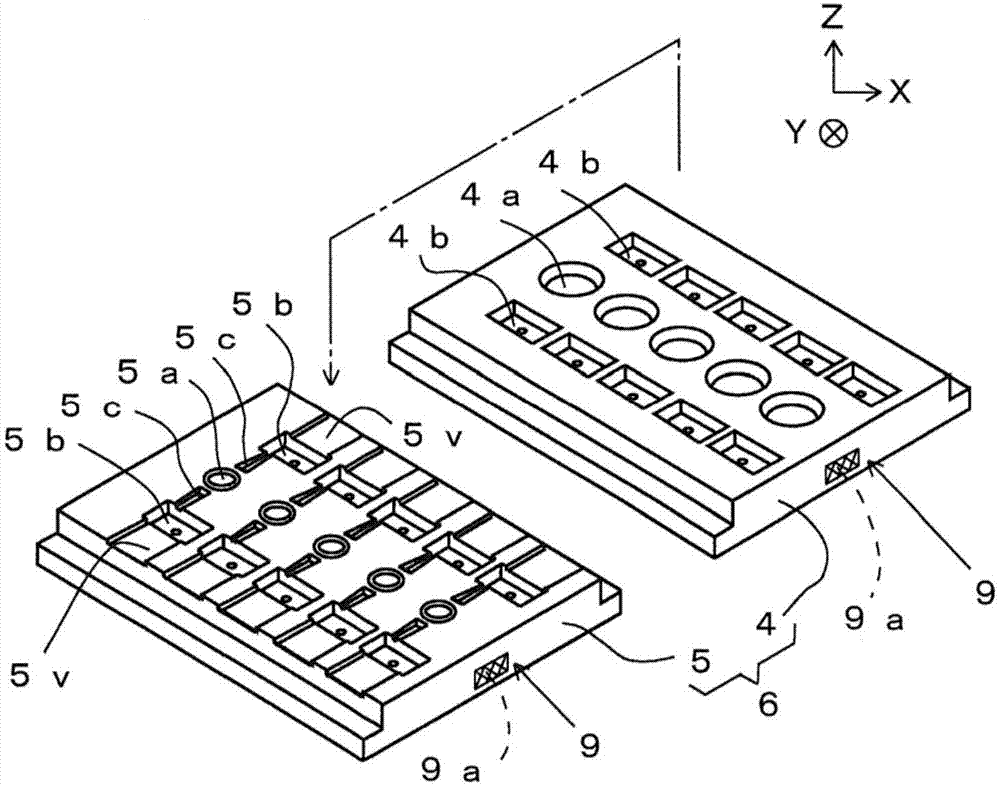

[0054] based on Figure 1A , Figure 1B and Figure 2A , Figure 2B , Embodiment 1 of the manufacturing apparatus and manufacturing method of the article of the present invention will be described. A resin sealing apparatus for electronic components will be described as an example of an article manufacturing apparatus. In the resin encapsulation apparatus of electronic components, the process of covering chip-shaped elements, such as a semiconductor chip, mounted on the board|substrate (lead frame, printed circuit board, etc.) with an encapsulation resin is performed. A packaged substrate corresponding to a molded product is completed by molding an encapsulating resin on a substrate (mounted substrate) on which a chip-shaped component is mounted using a molding die. Sometimes the packaged substrate itself corresponds to an article (finished product). The individual pieces after the packaged substrate is divided (cut) may correspond to articles (finished products). In thi...

Embodiment 2

[0104] Example 2 of the manufacturing apparatus and manufacturing method of the article of the present invention will be described. In this embodiment, the second information is stored in advance in a storage device provided outside the resin sealing device 1 . As the external storage device, the following two storage devices can be mentioned. The first storage device is a storage device included in a server or the like for a user of the resin sealing device 1 to manage the semiconductor manufacturing process. The second storage device is a storage device included in a server or the like used by the qualified product provider related to the resin sealing device 1 or the molding die 6 to manage its own products, services, and the like.

[0105] In this embodiment, first, a user of the resin sealing device 1 or the molding die 6 reads the second information from a storage device included in a server or the like for managing the entire semiconductor manufacturing process. There...

Embodiment 3

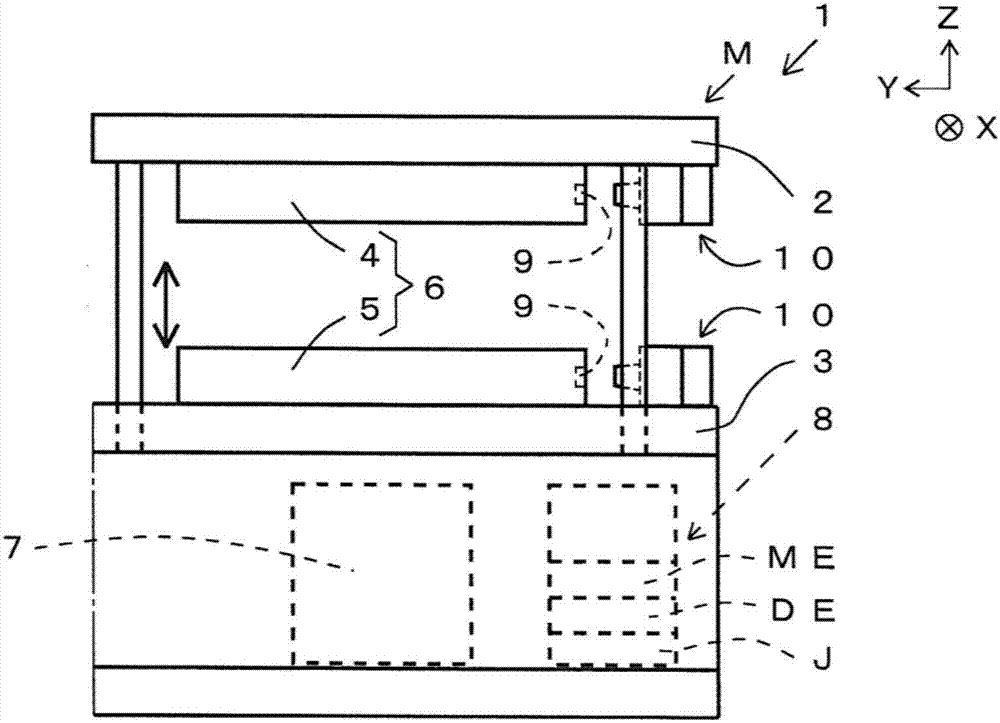

[0108] according to Figure 6Embodiment 3 of the manufacturing apparatus and manufacturing method of the article of the present invention will be described. Hereinafter, as the resin encapsulating apparatus 1 of the manufacturing apparatus, a resin encapsulating apparatus 1 using a compression molding method in which one cavity CAV is provided in the lower mold 5 will be described as an example. Figure 6 The shown forming die 6 is used at high temperature (eg, about 180° C.). Therefore, it is necessary to protect the information reading unit 10 from high temperature. This embodiment shows a preferable example of the information reading unit 10 for a replaceable member used at a high temperature.

[0109] Such as Figure 6 As shown, a ball screw 30 and a nut 31 are provided on the resin encapsulation device 1 . A main conveying mechanism 32 is mounted on the nut 31 . In order to allow the main transport mechanism 32 to move in the X direction, an X direction guide rail 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com