Color sand roller dryer

A drum dryer, drum technology, applied in sand drying, non-progressive dryers, dryers, etc., can solve the problems of uneven drying, low drum surface temperature, short falling time, etc., to avoid undrying , The effect of improving drying efficiency and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings.

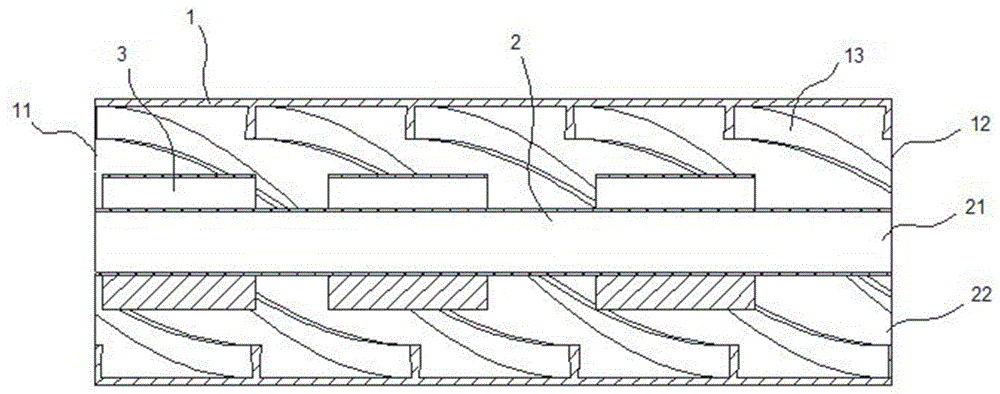

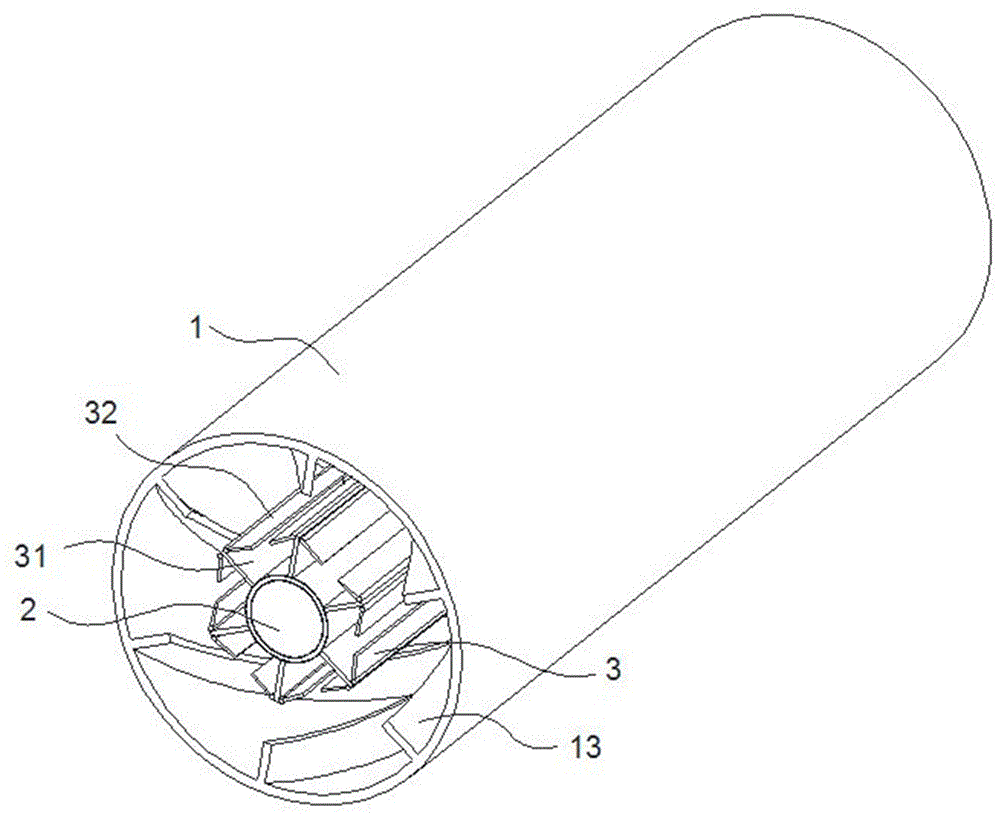

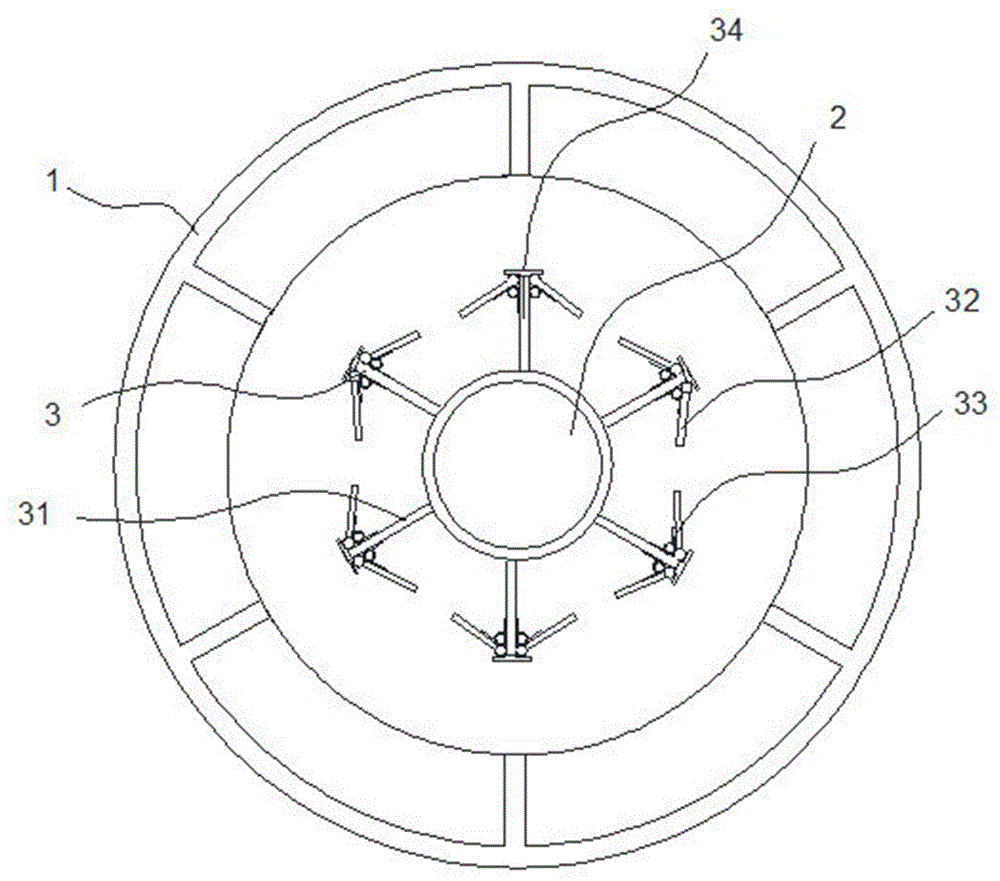

[0020] Such as Figure 1 to Figure 3 As shown, the dryer includes a rotatable drum 1. The drum 1 includes a feed end 11 and a discharge end 12. The inner surface of the drum 1 is provided with a helical blade 13. The material rolls in the drum 1 and under the action of the helical blade 13 Move down. There is an inner tube 2 inside the drum 1, one end of the inner tube 2 is an air inlet 21, and an air outlet 22 is arranged between the inner tube 2 and the drum 1 near the air inlet 21, and the hot air flows into the inner tube 2 from the air inlet 21 and passes through the inner tube The area between the cylinder 2 and the drum 1 is discharged from the air outlet 22; the outer side of the inner cylinder 2 is provided with scrap parts 3, and the scrap parts 3 include partitions 31 distributed along the circumference of the inner cylinder 2, and the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com