Light pressure-resistant buoyancy material for deep submergence vehicle and preparation method of buoyancy material

A technology of buoyancy materials and submersibles, which is applied in the field of marine engineering materials, can solve problems such as excessive buoyancy structure size, insufficient net buoyancy, and obstacles to submersible exploration, and achieve solidification at medium temperature, increase stirring efficiency, and excellent miscibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

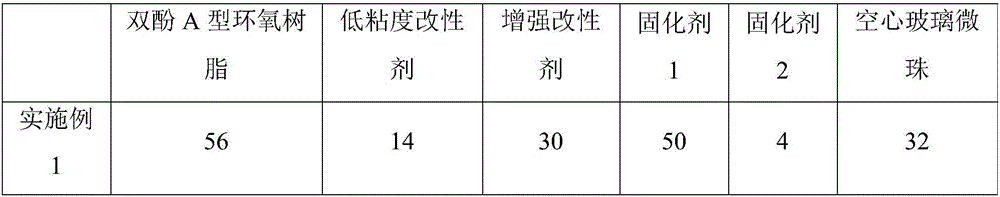

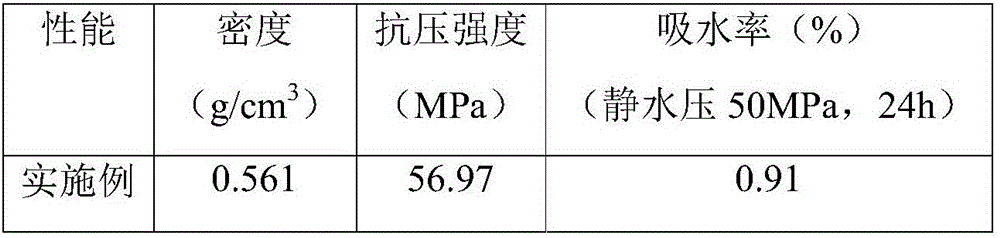

Embodiment 1

[0026] Prepare the lightweight pressure-resistant buoyancy material for deep-sea submersible according to the ratio in Table 1. The specific preparation method is as follows:

[0027] (1) Measured in parts by mass, take 56 parts of bisphenol A type epoxy resin, 14 parts of low viscosity modifier, 30 parts of reinforcement modifier, and 50 parts of liquid organic acid anhydride curing agent and 4 parts of liquid imidazole Add the curing agent into the mixing container with stirring and transposition, and stir evenly to obtain a resin glue with low viscosity characteristics;

[0028] (2) Measured in parts by mass, get 32 parts of hollow glass microspheres after drying and add them to the mixer, then add the resin glue obtained above into the mixer, and stir in vacuum;

[0029] (3) The stirring process temperature is room temperature 25°C to 30°C, the stirring speed is slowly increased from 0r / min to 30r / min, and the rising speed is controlled to increase by 1r / min every 2 seco...

Embodiment 2

[0040] Prepare the light weight pressure-resistant buoyancy material for deep-sea submersible according to the ratio in Table 3 respectively. The specific preparation method is:

[0041] (1) Measured in parts by mass, take 60 parts of bisphenol A type epoxy resin, 20 parts of low viscosity modifier, 20 parts of reinforcement modifier, and 45 parts of liquid organic acid anhydride curing agent and 6 parts of liquid imidazole Add the curing agent into the mixing container with stirring and transposition, and stir evenly to obtain a resin glue with low viscosity characteristics;

[0042] (2) Measured in parts by mass, take 33 parts of hollow glass microspheres after drying and add them to the mixer, then add the resin glue obtained above into the mixer, and stir in vacuum;

[0043] (3) The stirring process temperature is room temperature 25°C to 30°C, the stirring speed is slowly increased from 0r / min to 30r / min, and the rising speed is controlled to increase by 1r / min every 2 seco...

Embodiment 3

[0054] Prepare the light weight pressure-resistant buoyancy material for deep-sea submersible according to the ratio in Table 5 respectively, and the specific preparation method is:

[0055] (1) Measured in parts by mass, take 52 parts of bisphenol A type epoxy resin, 10 parts of low viscosity modifier, 38 parts of reinforcement modifier, and 55 parts of liquid organic acid anhydride curing agent and 3 parts of liquid imidazole Add the curing agent into the mixing container with stirring and transposition, and stir evenly to obtain a resin glue with low viscosity characteristics;

[0056] (2) Measured in parts by mass, get 32 parts of hollow glass microspheres after drying and add them to the mixer, then add the resin glue obtained above into the mixer, and stir in vacuum;

[0057] (3) The stirring process temperature is room temperature 25°C to 30°C, the stirring speed is slowly increased from 0r / min to 30r / min, and the rising speed is controlled to increase by 1r / min every...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com