Preparation method of water glass polyurethane flame retardant material

A flame retardant material and water glass technology, applied in the field of preparation of water glass polyurethane flame retardant materials, can solve the problems of high viscosity, low thermal conductivity, easy delamination of the system, and achieve the effect of increasing the addition ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

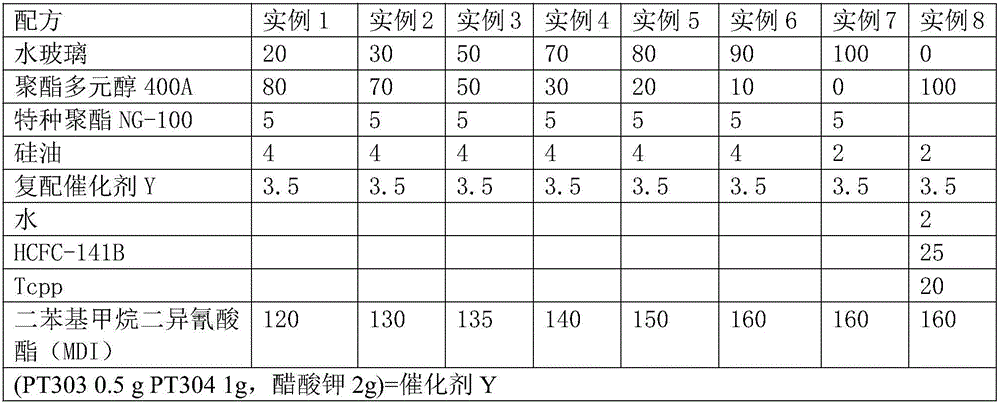

Embodiment 1

[0033] (1) Stir 20kg of water glass and NG-1005kg of special polyester at room temperature for about 10 minutes to obtain a transparent and uniform viscous liquid, then add 80kg of polyester polyol, 4kg of silicone oil and 3.5kg of catalyst Y in turn. Continue to stir In 30 minutes, the obtained material was referred to as A.

[0034] (2) Inject material A and raw material diphenylmethane diisocyanate (MDI) into a mold at 45°C through a high-pressure foaming machine at room temperature 25°C according to the weight ratio (1:1.3-1.6), and open it after 20 minutes of aging The required water glass polyurethane flame-retardant foam material is obtained after the mold is taken out, and finally the physical properties of the flame-retardant material are tested.

[0035] Different shapes of foam materials can be produced according to different mold configurations. The polyester polyol is produced by Zhangjiagang Nanguang Chemical Co., Ltd., and the diphenylmethane diisocyanate (MDI)...

Embodiment 2

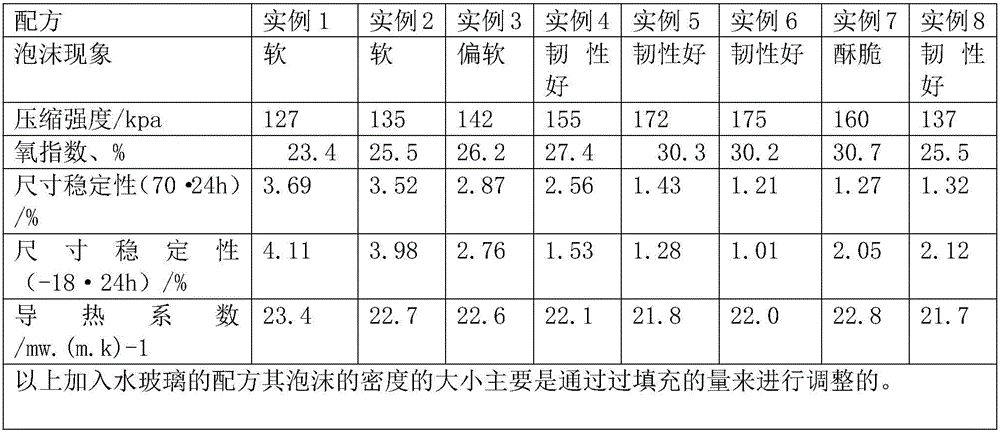

[0037] Prepare water glass polyurethane flame retardant foam material according to the method of embodiment 1. The specific formula is shown in Table 1

Embodiment 3

[0039] Prepare water glass polyurethane flame retardant foam material according to the method of embodiment 1. The specific formula is shown in Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com